Drinking water production line

4000 bottles/hour-72000 bottles/hour(500ml-20000ml)

PET small bottle of water: 150ml-1500 ml

PET large bottle water:

1200 bottles/hour -16800 bottles/hour; Applicable bottle size 3000m1-7000ml

1000 bottles/hour -6000 bottles/hour; Suitable for bottle size 7000m1-20000ml

I 、Capacity range:

A. Our intelligent manufacturing solutions for different customers.

B. New customized drinking water production line.

C. Main equipment scheme selection (for reference)

D. Equipment selection principle:

1) The product has strong adaptability, complete functions, high degree of automation, maturity and stability, low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, good reputation.

4) Aim at the domestic advanced level as far as possible, giving priority to the use of mature and advanced equipment to achieve the processing of its key processes.

II、Dedicated to providing full line customized solutions for Liquid Packaging products

A.Dedicated to providing a full range of customized solutions for liquid packaging products

B.What kind of packaging do you need to design? Bottle label cover label, labeling (self-adhesive or hot melt adhesive).

C.Your water source comes from underground Wells or surface natural mountain springs,etc

D.The nominal capacity of the bottle is such as 500ml bottle, and there are several other volume bottles respectively

E.Does the difference in bottle mouth and cap and automation requirements affect how the equipment is selected?

F.Our whole factory turnkey engineering services, so that customers more worry and the whole line before and after a high degree of cooperation, good stability.

PET bottle water production line packaging solutions:

Applicable product:

Pure water, mineral water, mountain spring water, etc

Applicable container:

Water packaging series: Various capacity square bottles and round shape PET bottles, glass bottles, cans, etc., can be tailored for you.

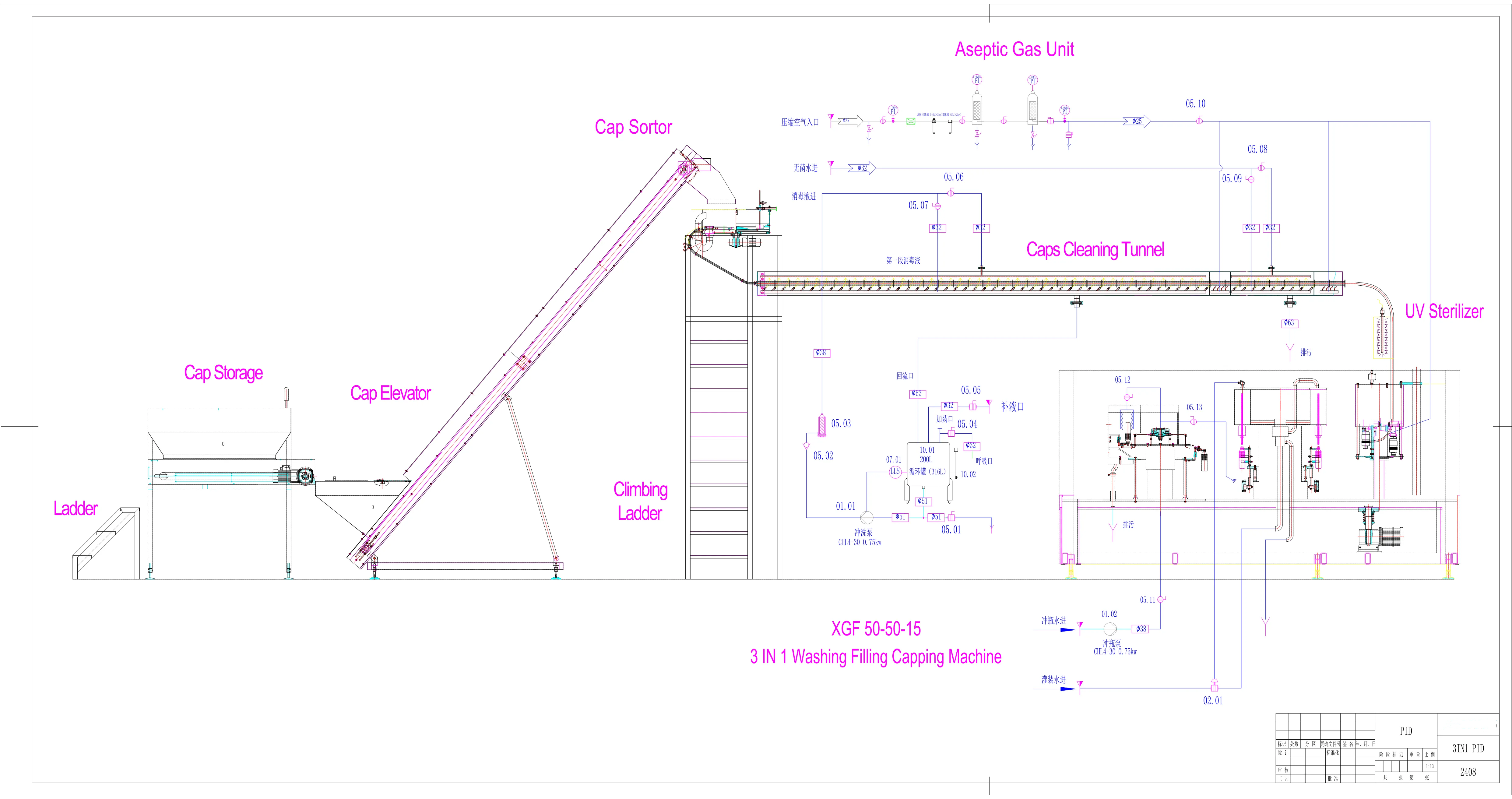

III 、Our customized PID process design for bottled water production line

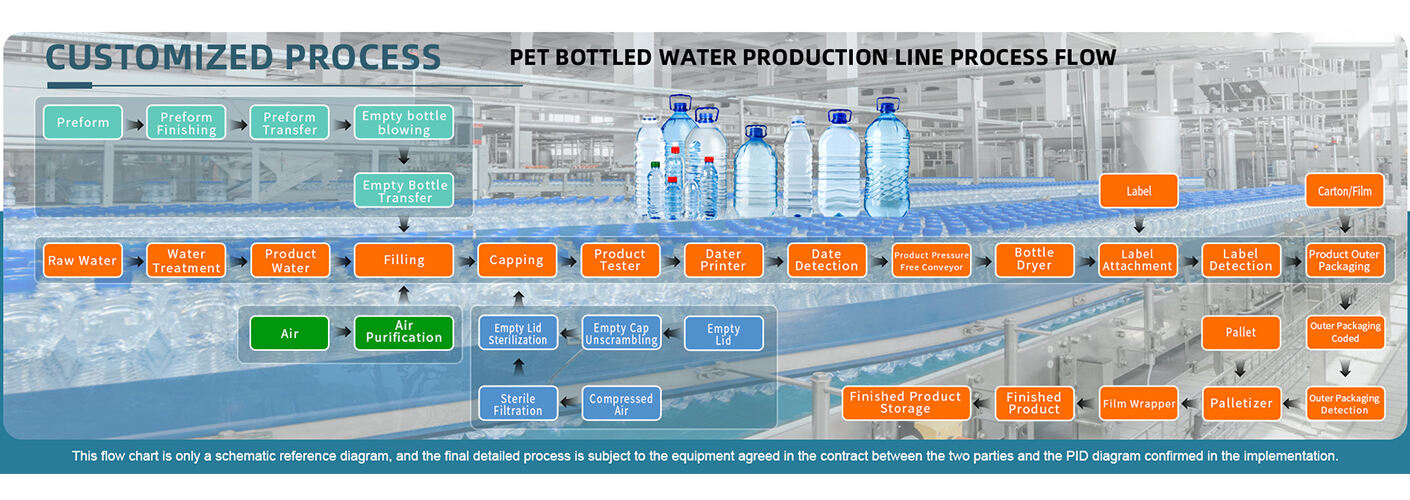

IV 、 Whole plant project PET bottled water production line process flow:

(How to build a complete bottled water production line, our company with the most professional technology to answer your questions and give reasonable planning suggestions.)

V 、The relevant advantages of our equipment are introduced

Blowing and spinning:

Energy consumption compared with domestic counterparts, saving more than 30% of electricity, saving more than 10% of gas, taking 24,000 blowing and spinning production lines as an example, according to the production of 22 hours per day, 280 days per year, only electricity (blowing and air pressure) one, can save about 550,000 / year. Fully embodies the design concept of high efficiency, energy saving, safety and environmental protection.

Blow molding machine:

(We give you a variety of bottle design compatible with a blow machine equipment to complete blowing)

Our company blow light bottle 5.5g can blow 350ml water bottle,9.8g blow 500ml water bottle;

China is the first to develop large bottle water blowing and spinning production line 5-20 liters PET bottle disposable packaging drinking water;

Filling machine:

(If you plan to build a new factory: considering the production of bottled water and want to produce soft drinks, our filling machine can complete a variety of materials compatible filling with one)

Water line:

Specially designed for the production of pure water or natural spring water filling valve, fast flow rate, precise level control, independent non-polluting return system, optimized internal structure of the valve body, can achieve thorough CIP cleaning, representing the highest level of domestic filling technology.

Filling method:

Mechanical valve filling, flowmeter filling, weighing filling or laser fixed level filling

VI 、Well-designed and built for customers the whole plant engineering integrated intelligent solutions.

Please carefully refer to your better choice!