Aseptic filling line

A、Capacity range:

production capacity

5000 bottles/hour – 36000 bottles/hour

1. Our intelligent manufacturing solutions for different customers.

2. New customized drinking water production line.

3. Main equipment scheme selection (for reference)

4. Equipment selection principle:

1) The product has strong adaptability, complete functions, high degree of automation, maturity and stability, low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, good reputation.

4) Aim at the domestic advanced level as far as possible, giving priority to the use of mature and advanced equipment to achieve the processing of its key processes.

B、Dedicated to providing a full range of customized solutions for liquid packaging products

1.What kind of packaging do you need to design? Bottle label cover label, labeling (self-adhesive or hot melt adhesive).

2.The nominal capacity of the bottle is such as 500ml bottle, and there are several other volume bottles respectively

3.Does the difference in bottle mouth and cap and automation requirements affect how the equipment is selected?

4.Our whole factory turnkey engineering services, so that customers more worry and the whole line before and after a high degree of cooperation, good stability.

C、Solution for aseptic filling and packaging of PET bottles: (Display production pictures of blowing, filling, and spinning at the customer's site)

Applicable Products:UHT milk, normal temperature yogurt, tea, juice, coffee, functional drinks, vegetable protein, liquid milk, etc All types of liquid food

Suitable Container:PET bottles of various shapes and capacities

Filling Method:Non-contact filling Room temperature filling (25-30℃)

Production Capacity:5000 bottles/hour – 48000 bottles/hour

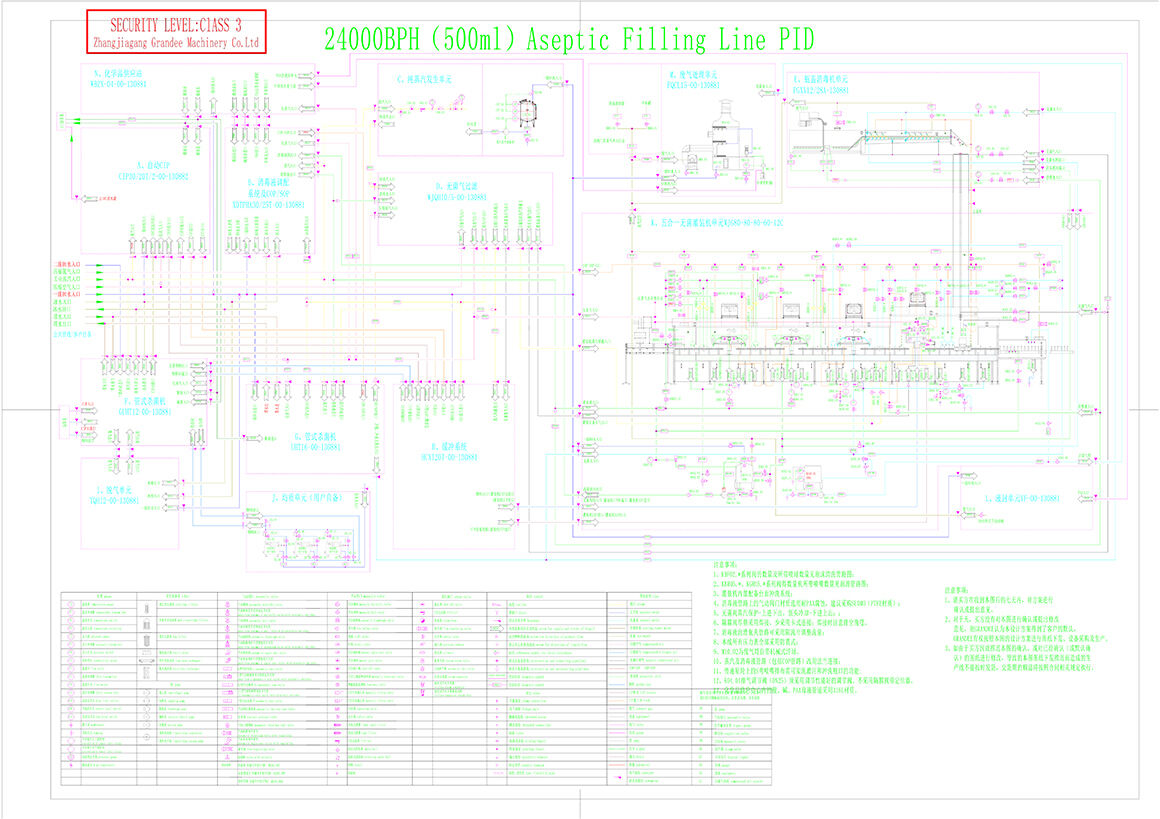

D、Our customized PID process design for bottled water production line

PID picture

E、Whole plant project PET bottled water production line process flow:

How to build a complete aseptic cold filling beverage production line, our most professional technology to answer your questions and give you reasonable planning suggestions.

F、The relevant advantages of our equipment are introduced

1、GRANDEE with mature low, medium and high speed PET bottle aseptic filling technology, the technology has a wide range of product applicability. For high-acid and low-acid products, the sterilization efficiency of the entire system can reach 5D or 6D. The sterilization process is divided into wet sterilization and dry sterilization, which are used for the sterilization of packaging materials such as bottles and caps and the environment. The sterile area is achieved by means of isolators, and the graded clean space inside the unit is maintained by positive pressure.

2、Dry and wet equipment (dry blowing and spinning process advantages of energy saving: water, electricity, gas, disinfectant) : dry blowing and spinning covers less area: 20-30%, save energy (save steam, reduce sewage discharge, save the amount of disinfectant, filling main machine and auxiliary machine application to save electricity), the use of dry process production line to produce milk, juice and other beverages greatly reduces the cost, while improving product competitiveness.

G、Perfect packaging for all neutral and other beverages.

H、Aseptic filling equipment: fully automatic finishing of bottle embryo, bottle embryo conveying, embryo dust removal, embryo sterilization, embryo heating, blowing, bottle testing, aseptic filling, cap arrangement, cap sterilization, capping, servo screw cap, bottle out and finished product conveying.

1.It can be compatible with gas aseptic filling, non-gas aseptic filling and fruit filling.

2.Advanced bottle sterilization technology and linear/rotary equipment architecture.