Capacity Range:

5000 bottles/hour -48000 bottles/hour; for the bottle types of 150ml-1500ml

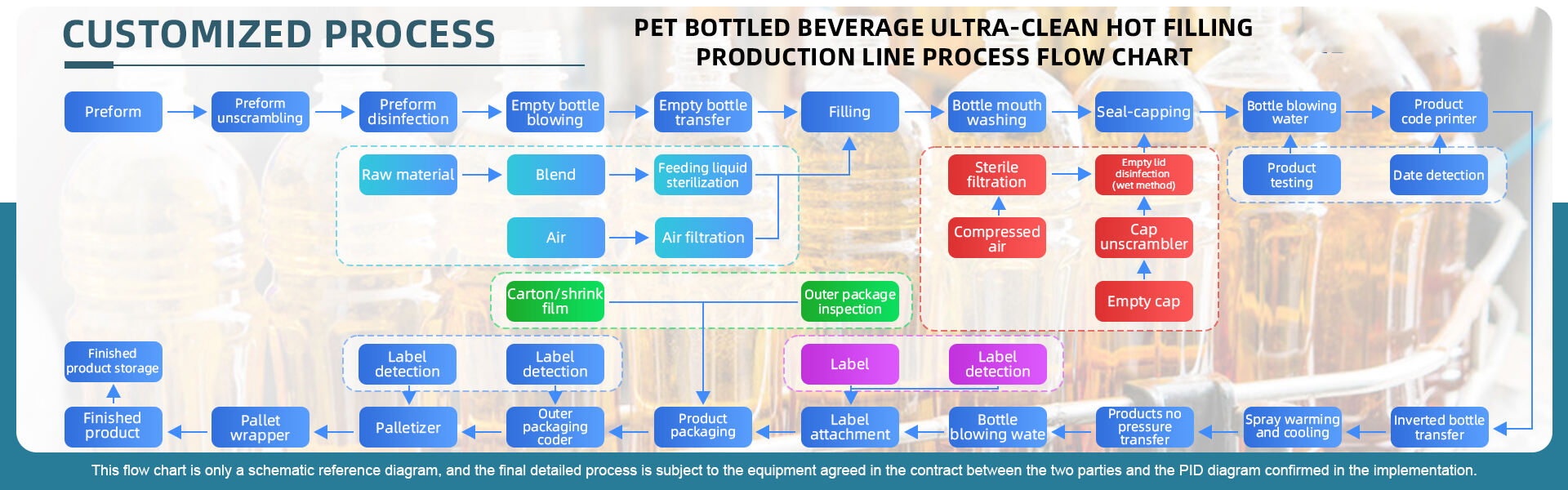

Ultra-Clean Blowing-Filing-Capping Combiblock integrates functions of blowing, disinfection, cleaning, filling and capping to ensure the health and safety of beverages. The technology can be divided into ultra-clean hot filling (82-92 °C), ultra-clean medium temperature filling (68-72 °C), ultra-clean normal temperature filling (16-25 °C), ultra-clean cold filling (4- 15°C).

I 、Equipment selection principle:

1) The product has strong adaptability, complete functions, high degree of automation, maturity and stability, low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, good reputation.

4) Aim at the domestic advanced level as far as possible, giving priority to the use of mature and advanced equipment to achieve the processing of its key processes.

Application Scope:

Mainly used for packaging PET bottles of juice, liquid milk, tea, energy drinks, etc.

Suitable Container:

Suitable for PET, PE, PP, PS and other plastic packaging containers. You can choose ultra-clean and clean versions, fully automatic bottle feeding, ion dust removal, bottle sterilization, filling (weighing or flowmeter), cap sterilization, cap screw, bottle out, sealing with anti-theft plastic cap screw or aluminum film cap heat seal. With one key switch function, various bottle type switch on the man-machine interface button to achieve.

III 、Our customize PID

IV 、 Whole plant project

IVV 、Feature

Ultra-clean filling equipment adopts ultra-clean filling process, the sterilization efficiency of the contact surface of packaging materials and materials SE≥3, and the filling and sealing area should meet the N6 clean room requirements stipulated in GB 50073-2013 "Clean Workshop Design Code".

Gas filled filling technology:

1.Mechanicalor volumetric electronic filling valve;

2.Tubular type filling bowl no dead angle, easy to clean;

3.Automatic CIP,easy for operation and maintenance;

4.Raise filling temperature above 12~15°C for energy

saving;

5. Volumetric valve leads to high filling precision,5~6

times higher than mechanical valve;

6.Volumetric valve filling can realize fast changeover, no vent tubes

Filling technology for fruit juice, tea, beverages, etc:

1. Hot filling or aseptic filling technology available;

2. For hot fill, product return during machine stop to keep valve body temperature;

3.Product return volume adjustable as per request,e.g.5~15%;

4. Filling valve design could be mechanical valve with product return, or upgraded to be electro-pneumatic valve or flow meter valve, simple flow structure, easy forCIP, no leakage;

5. Advanced CIP structure design no dead angle, downstream and upstream clean available;

6.Two steps filling in case fruit pulp size bigger than 5x5x5mm;

7. Enclosed structure with HEPA filter or exhaust system to guarantee clean filling area(Option)