ALL PRODUCTS

-

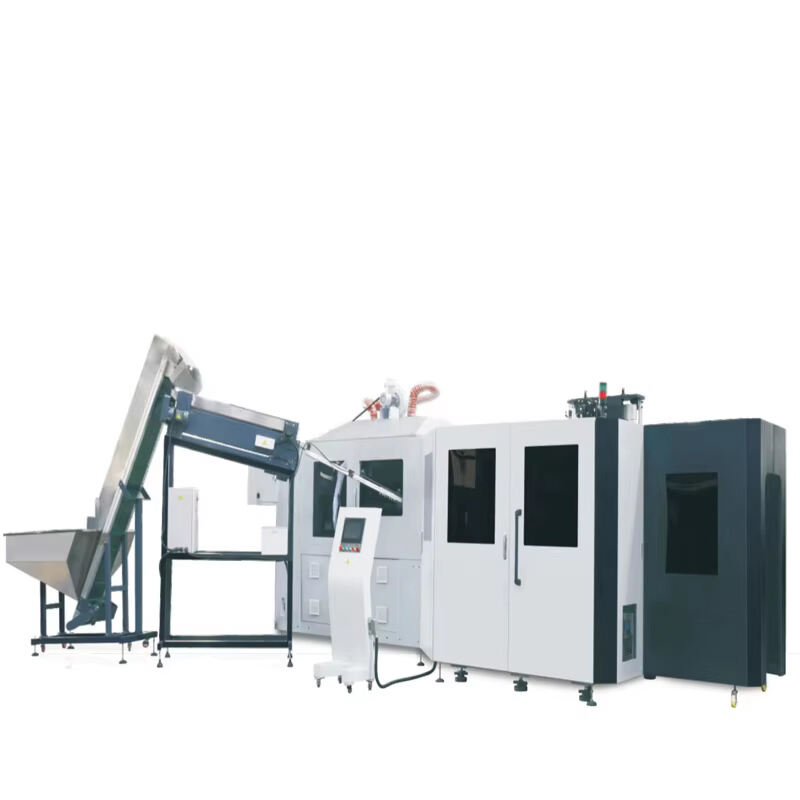

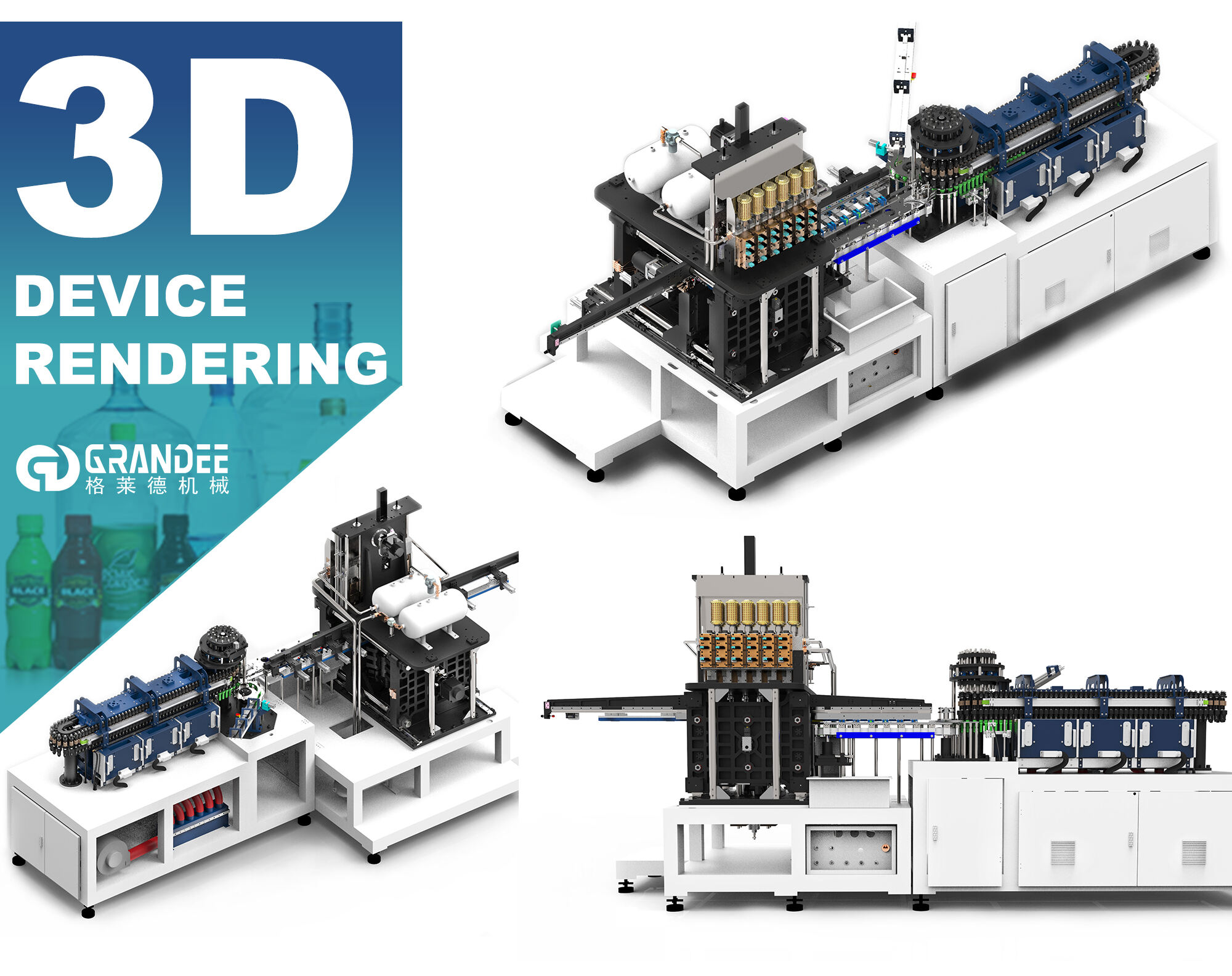

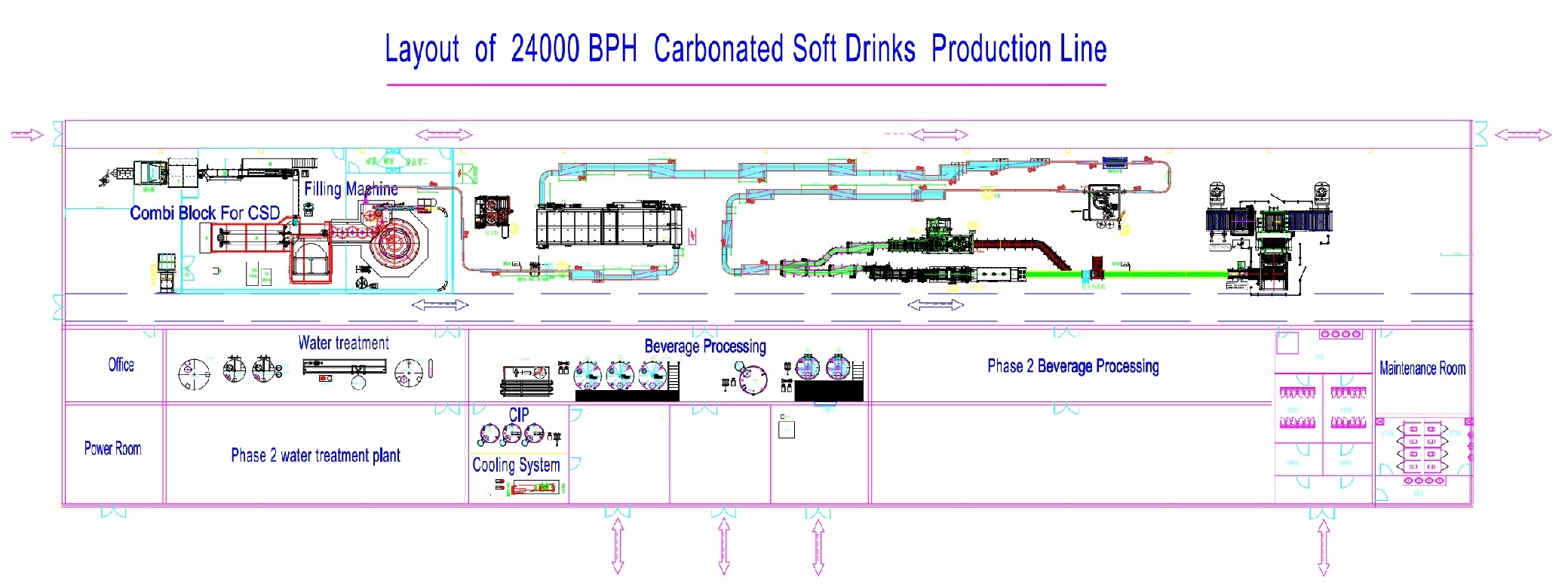

Combi Block

-

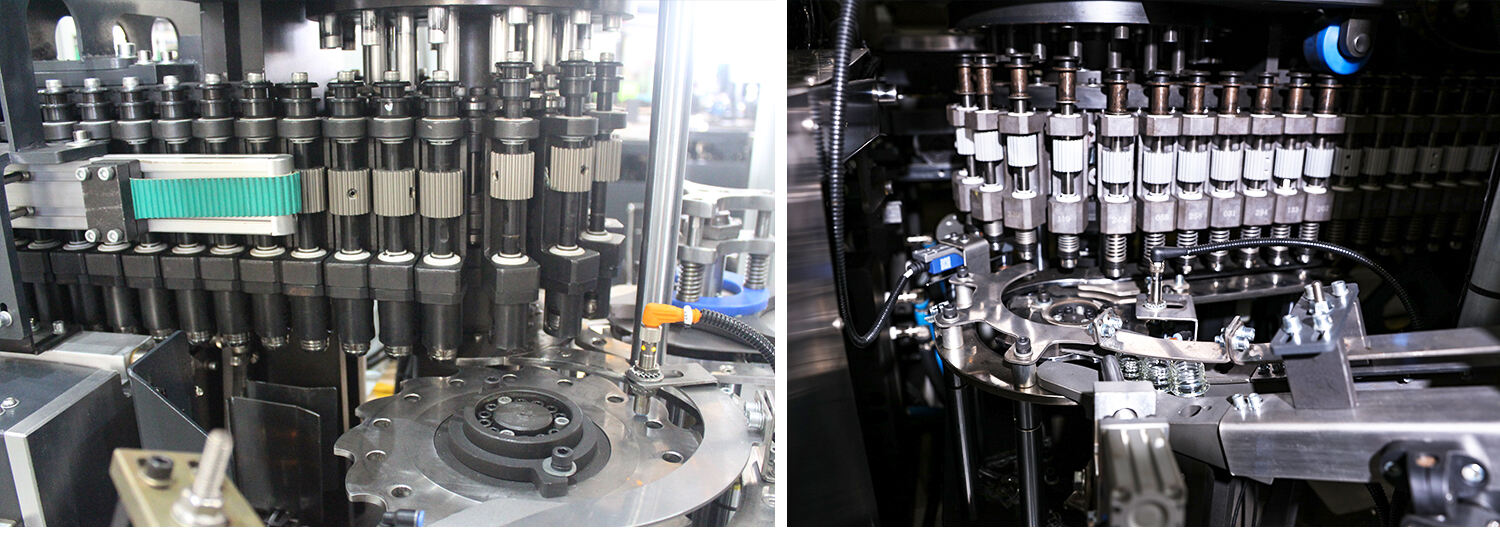

Filling Machine

- Oil Filling

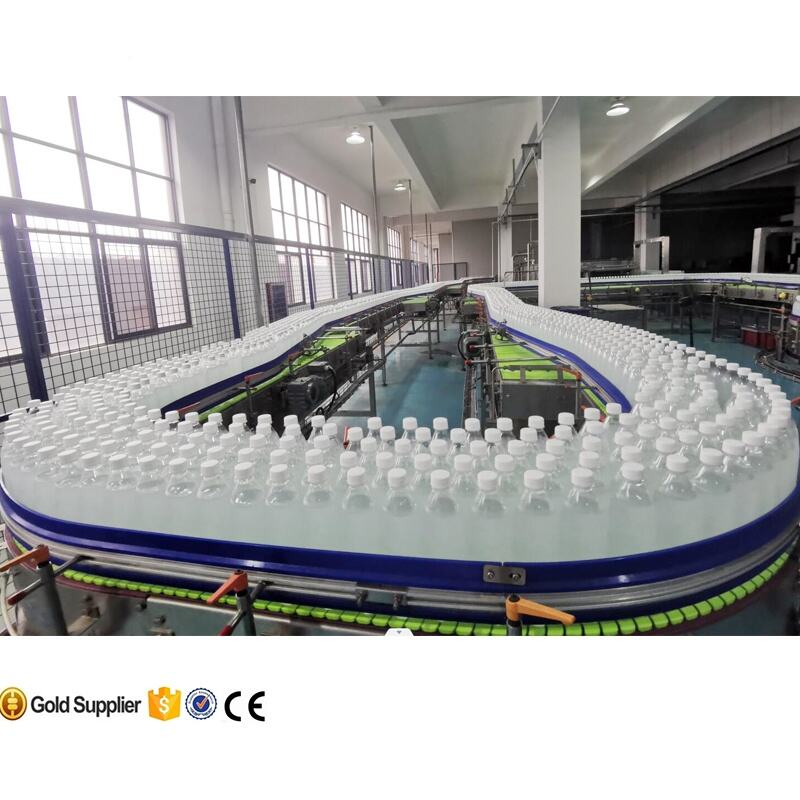

- Water Filling for Small Bottle

- Chemical Filling

- Water Filling for 3~20L Bottle

- Glass Bottle Filling for Wine

- Glass Bottle Filling for Condiment

- Glass Bottle Filling for Beer

- Glass Bottle Filling for CSD

- Glass Bottle Filling for Juice

- Can Filling for Beer

- Can Filling for CSD

- Can Filling for Juice

- Aseptic Filling

- CSD Filling

- Juice Filling

- Water Filling for 5 Gallon Bottle

-

Beverage Processing System

-

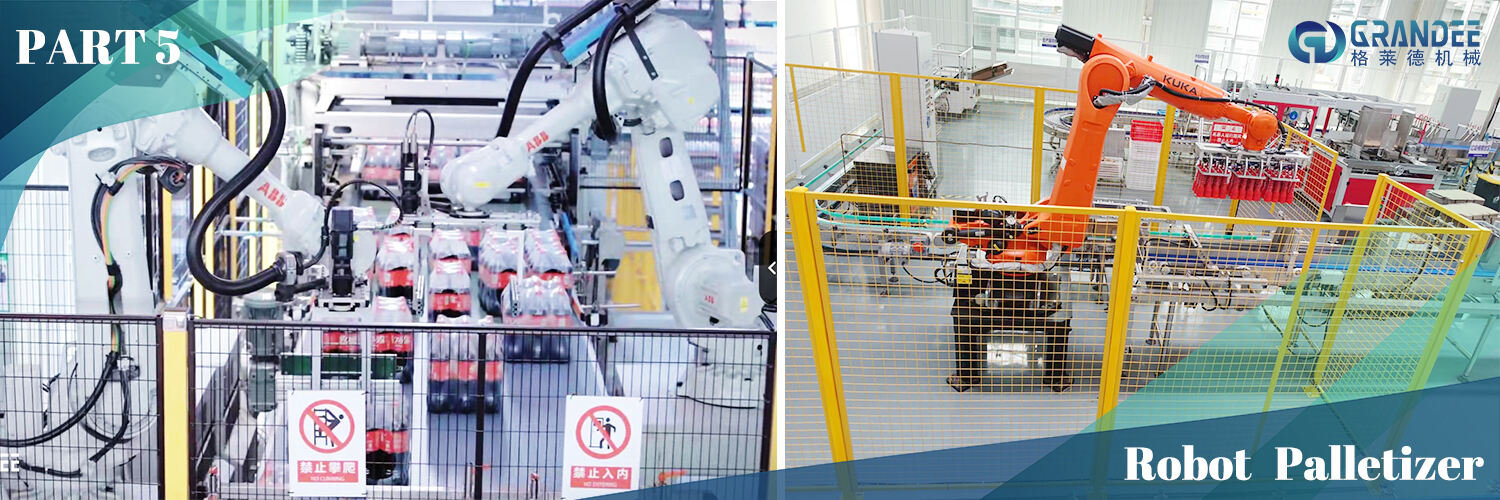

Labeling & Packaging Machine

-

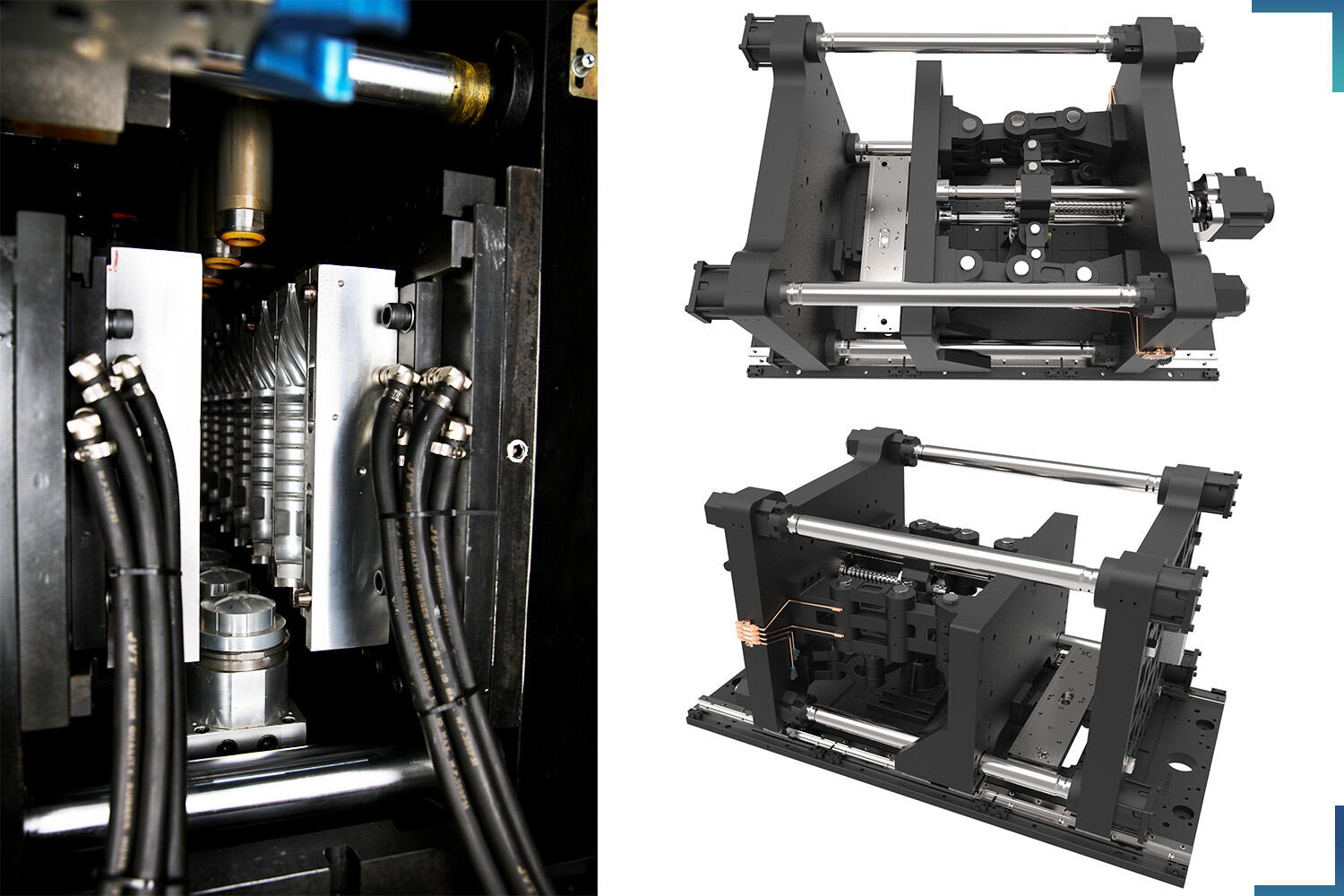

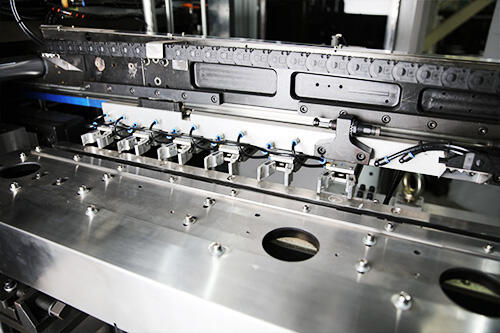

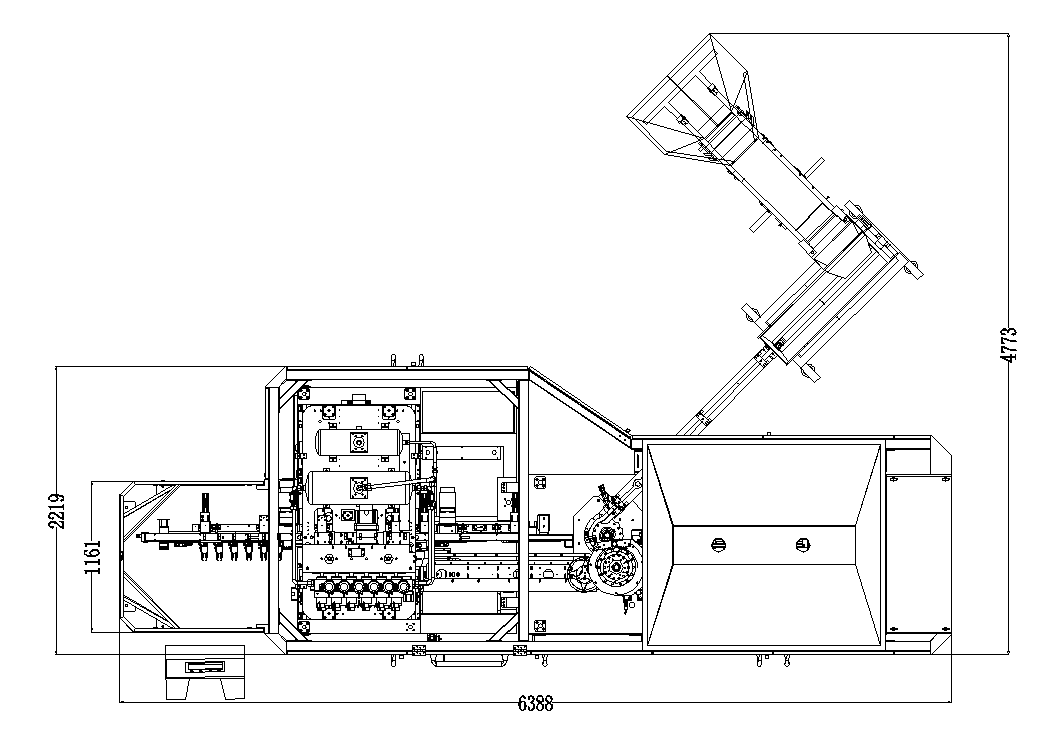

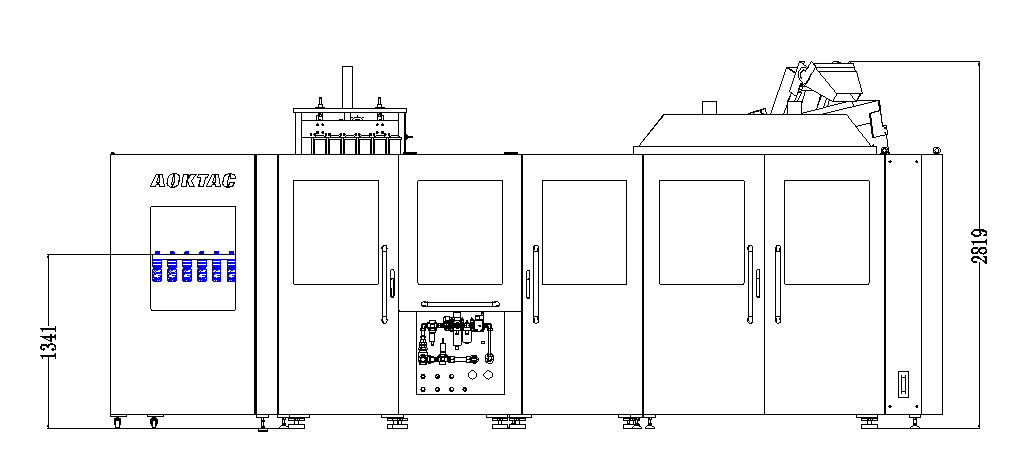

Bottle Blowing Machine

-

Injection Moulding Machine

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM