GRANDEE MACHINE

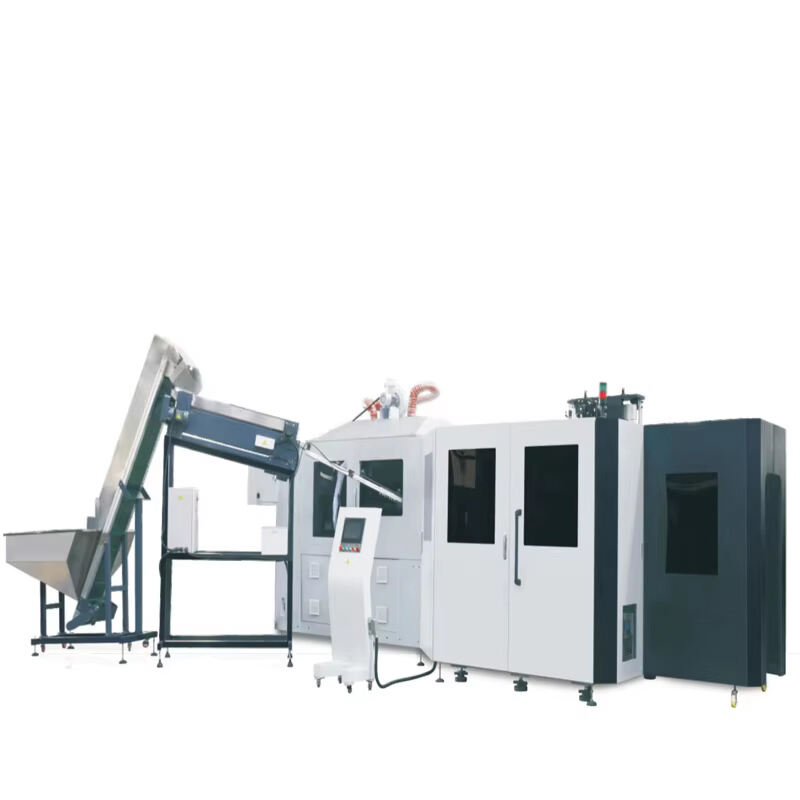

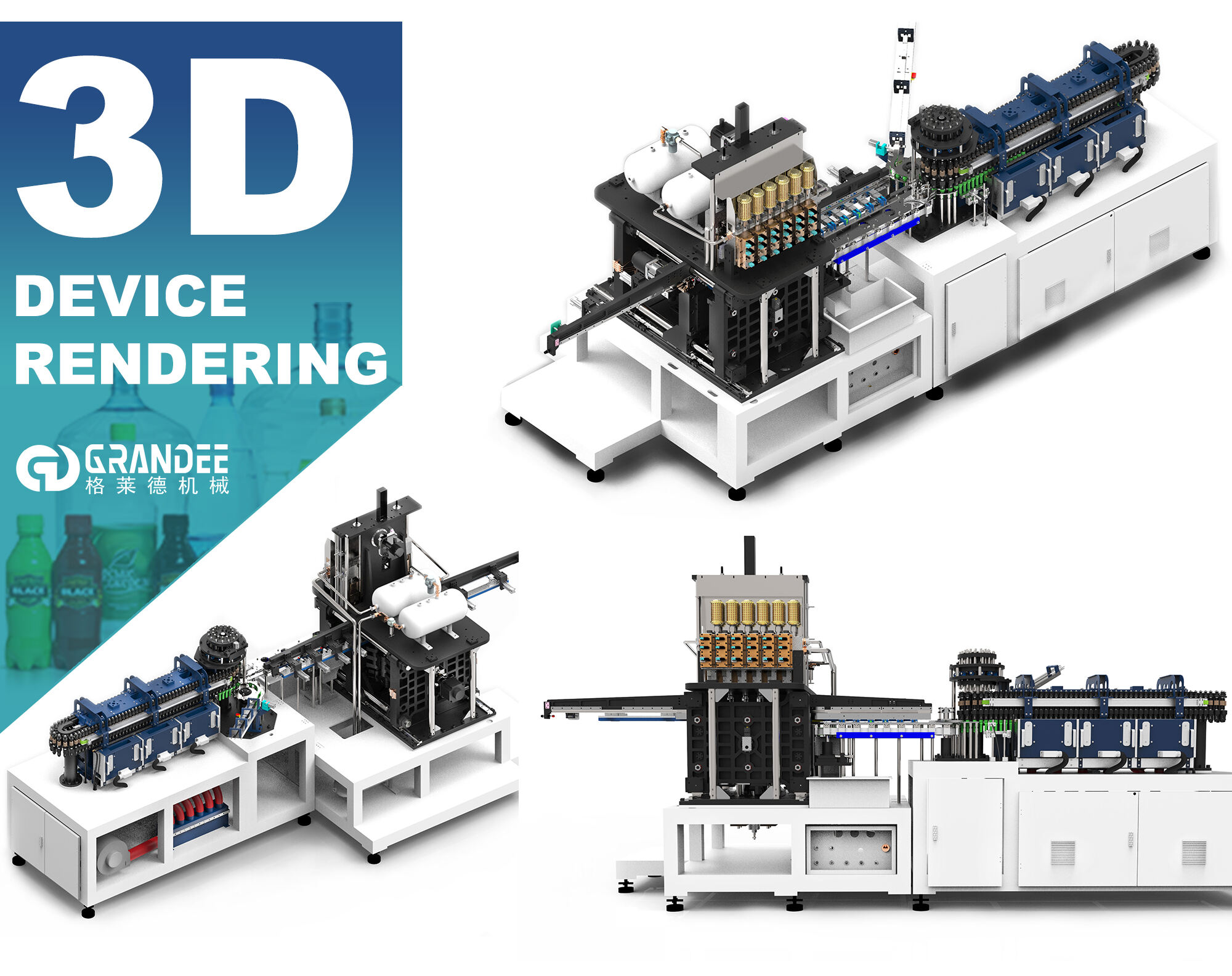

High speed automatic pet plastic water bottle blowing mold molding machine price brings you the technology latest in pet synthetic water container molding with their brand-new High Speed Automatic Pet Plastic Water Bottle Blowing Mold Molding device. This revolutionary product ideal versatile creating water containers in a number of sizes.

The apparatus is totally automated that makes it quite simple to utilize. It is laden up with a servo high-speed which means that the apparatus operates with amazing rate and accuracy. It creates up to GRANDEE MACHINE 2000 containers each full hour making this perfect for both tiny and manufacturing large-scale.

The gear is made of top-quality metal gives it a sleek and appearance modern. Its design compact means calls at a lower price room and will match Bit manufacturing surroundings. This allows you to wash and keep allowing you to conserve effort and time.

Another function outstanding of High-Speed Automatic Pet Plastic Water Bottle Blowing Mold Molding device is its energy-saving mechanisms. The apparatus uses less power which supports preservation ecological. and this means the product shall allow you to save on power expenses in to the run very long.

The unit is wholly computerized having a screen user-friendly is simple to exert effort. It features a security sensible that detects any pressing issues or malfunctions while offering instant feedback rendering it an easy task to troubleshoot and correct any issues. Which means manufacturing processes aren't interrupted and any dilemmas can very quickly be fixed.

This High-speed automatic pet plastic water bottle blowing mold molding machine price device was made with security in your mind. A security is had due to it home that stops any accidents from taking place during manufacturing. Its security features ensure that the apparatus shall perhaps not begin until all things are correctly put up making sure every person around is safe.

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

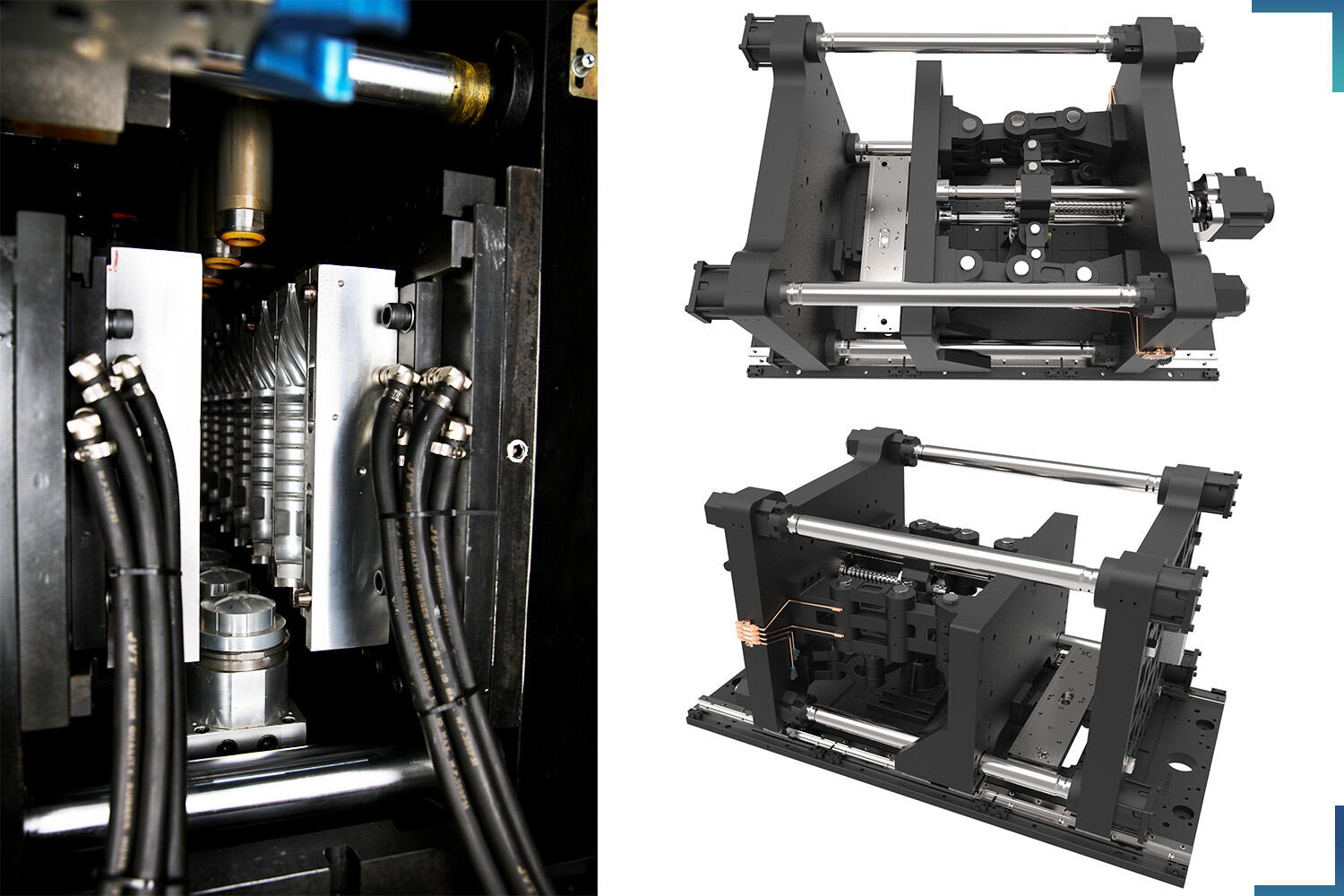

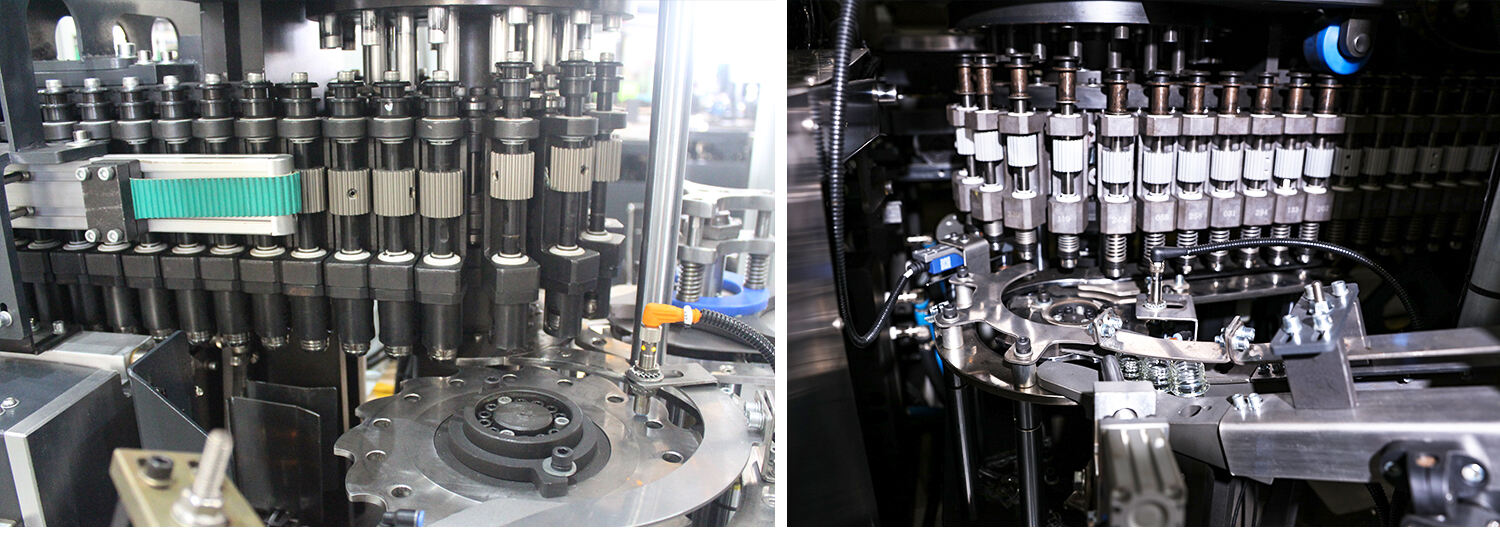

[1] Clamping Unit:

servo motor drives the reducer for clamping and opening, bottom cam system works together for mold open and close.

[2] Stretch unit:

servo motor driven, gear and rack system to achieve high speed.

[3] Ceramic refection board system:

adopt Swiss ceramic reflection board to achieve high reflection efficiency, save power and high efficiency.

[4] Continuous splitting mechanism:

Adjust the pitch of the heated bottle blank (38.1mm) to the center distance required for blowing (114.3mm), achieving the goal of energy conservation. The clamping component includes at least 4 pneumatic fixtures with an opening angle of 180 degrees; The pneumatic fixture is driven by a cylinder to open the clamp block 180 degrees, so that when the pneumatic fixture is opened, the clamp block is parallel to the conveyor belt for transporting the bottle preform, ensuring that the pneumatic fixture does not need to move vertically when returning to pick up the bottle preform, but only needs to move horizontally. It not only saves time, simplifies the structure, but also reduces unnecessary shaking.

[5] Combination high-pressure blowing valve:

The valve body operates sensitively and has a fast response speed, with a short blowing time cycle, increasing production capacity and reducing energy consumption.

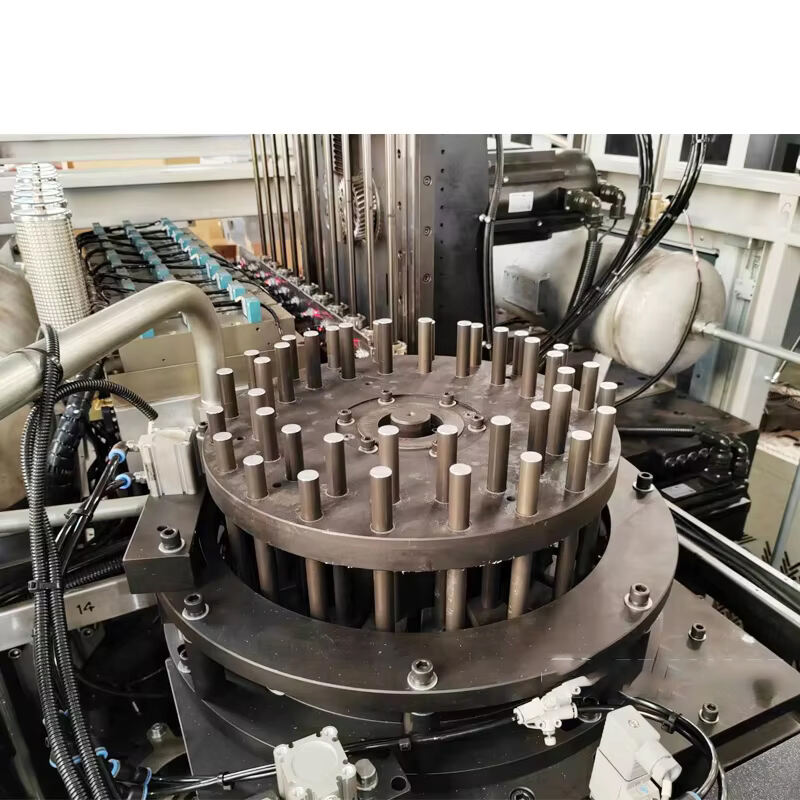

[6] Star wheel preform feeding system:

a linked type preform feeding star wheel disc, with the oven and star wheel disc linked, reliable and stable one-on-one preform feeding, ensuring that there is no omission of preforms.

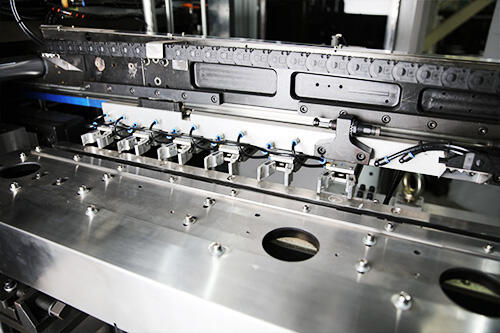

[7] Air intake system:

The air source cooling water is centralized at the inlet, avoiding disorderly external pipelines. The entire set adopts Japanese SMC components, making the air source more stable

|

Model

|

Unit

|

GD-6II

|

|

|

|

|

Clamping System

|

Number of cavity

|

cavities

|

6

|

|

|

|

|

mold stroke

|

mm

|

0-130

|

|

|

|

(stretch stroke

|

mm

|

340

|

|

|

|

Bottom stroke

|

mm

|

50

|

|

|

|

Cavity pitch

|

mm

|

114.3

|

|

|

|

heating pitch

|

mm

|

50.8

|

|

|

|

Number of holder

|

PCS

|

96

|

|

|

|

Container

|

Max. container volume

|

ltr

|

1.5

|

|

|

|

|

Max. neck diameter

|

mm

|

30/48

|

|

|

|

Max. perform height

|

mm

|

120

|

|

|

|

Max. container diameter

|

mm

|

95

|

|

|

|

Max. container height

|

mm

|

340

|

|

|

|

theoretical output

|

|

B. P. H

|

9000

|

|

|

|

Electrical System

|

heating oven

|

UNITS

|

5

|

|

|

|

|

box*channel

|

layer

|

10

|

|

|

|

Number of lamp

|

pcs

|

50

|

|

|

|

heating power

|

KW

|

60

|

|

|

|

AVERAGE POWER

|

KW

|

24

|

|

|

|

installed power

|

KW

|

72

|

|

|

|

voltage

|

Voltage

|

220v/380V/3phase

|

|

|

|

Air System

|

operating pressure

|

kg/cm2

|

7

|

|

|

|

|

blowing pressure

|

mpa

|

3.0-3.8

|

|

|

|

high pressure air consuming

|

L/min

|

8

|

|

|

|

Chiller System

|

temperature

|

°C

|

10-15

|

|

|

|

|

pressure

|

Mpa

|

0.4

|

|

|

|

flow rate

|

L/min

|

80

|

|

|

|

heating power

|

HP

|

8

|

|

|

|

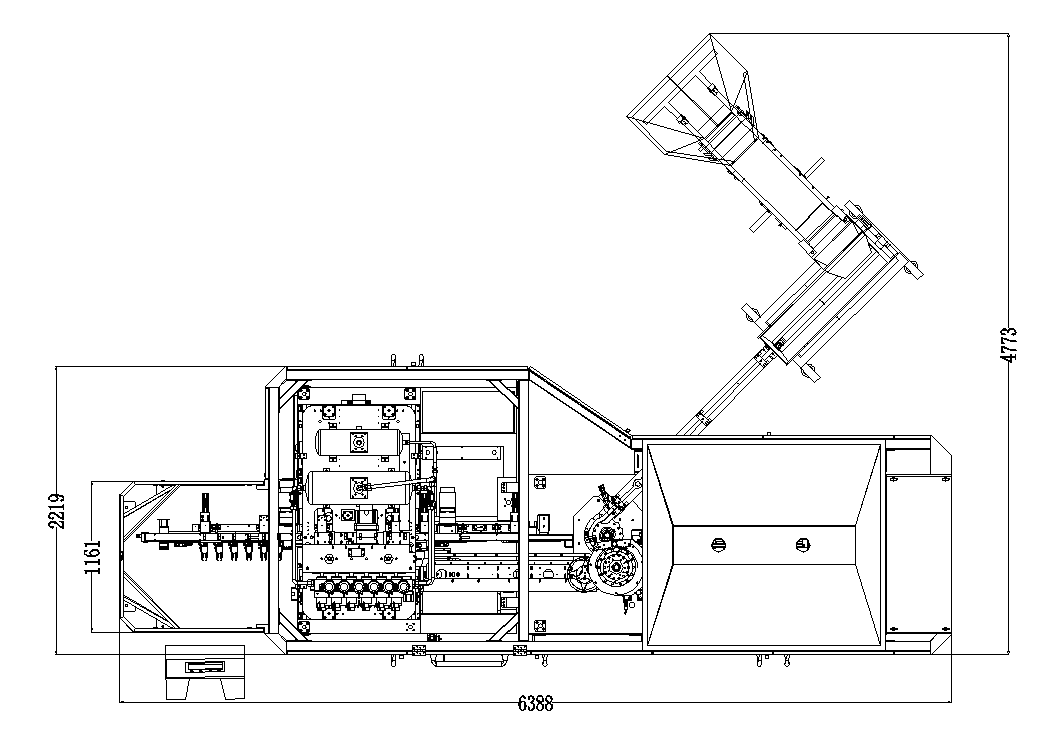

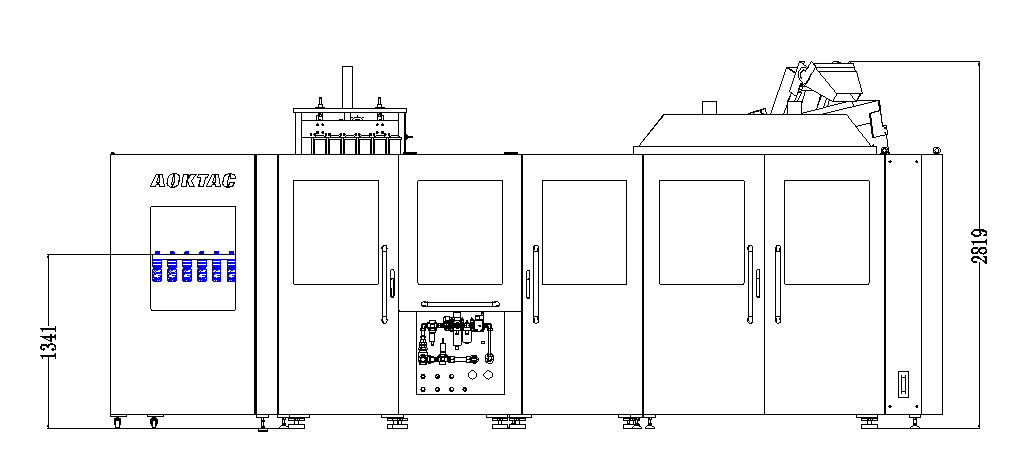

Machine

|

machine dimension

|

M

|

1.0*3.5*2.5(heating)

|

|

|

|

|

|

|

2.5*2.0*2.5(machine)

|

|

machine weight

|

KG

|

8000

|

|

|

One stage or Second stage R. O. Water treatment system

Raw Water Tank→ Raw Water Pump→ Quartz Sand Filter→Activated Carbon Filter→ 5 Micron Filter→ 1 Micron Filter→High Pressure Pump→Primary Reverse Osmosis Device→Intermediate Water Tank→ Booster Pump→ (Secondary High Pressure Pump→Secondary Reverse Osmosis Device) → Ozone Mixer→Pure Water Pump→ Pure Water Tank→ External Supply Pump→ Titanium Tube Filter→ External Supply→ To Filling Machine

Automatic OPP BOPP hot melt Glue labeling machine

Automatic BOPP labeling machine is widely suitable for different material of containers and labels. The cost of each label is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is one of the most economical models to make mass production and integrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, like changing the label is only needed to change the PLC program, the products concept that the equipment is used for users and considered for users is embodied in everywhere.

Automatic PVC PE Sleeve Shrink Labeling Machine

This fully automatic sleeve labeling machine is suitable for various kinds of bottles, like round bottles, square bottles, oval bottles, etc. This machine can automatically feed and cut film, and it can sleeve labels precisely, greatly saving labor and improving work efficiency. The machine can be widely used for beverage bottles, cosmetic bottles, shampoo bottles, etc.

Operating Principle Of Packaging Machine

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping.

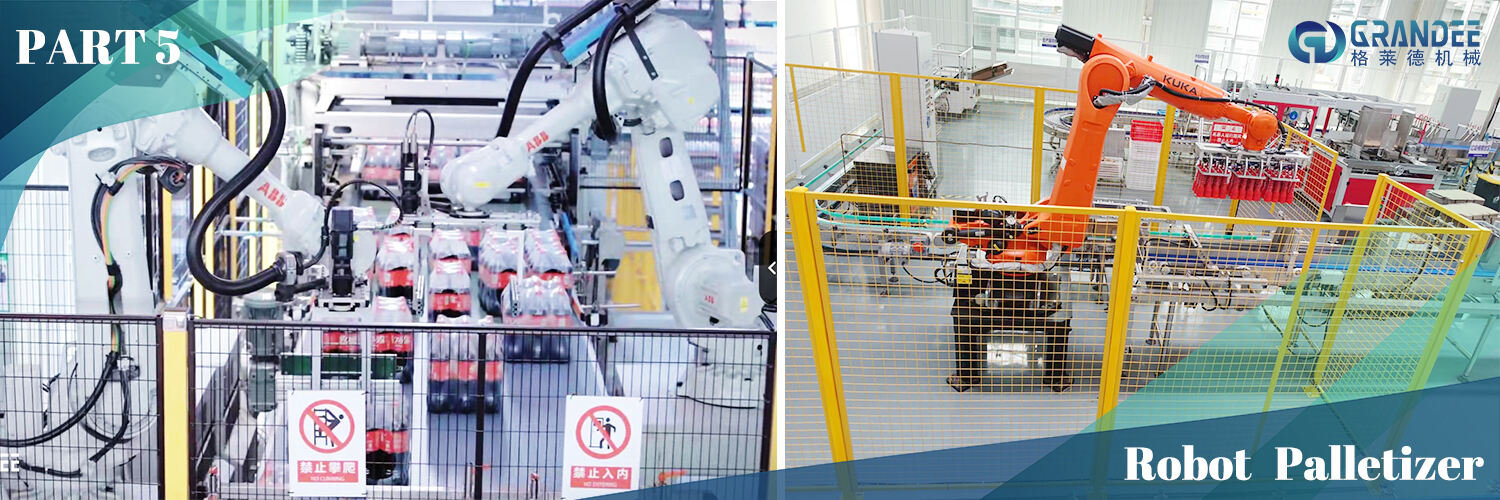

Robot Palletizer

Which contribute to the robot of the pallet system has a compact body and a high throughput. It is suitable for packing bottled drinking water, juice, carbonated soft drinks etc. with production capacity up to 520layer/h. Suitable robot models can be selected according to the work pieces. Payload 110kg, 140kg, 185kg, 315kg, 5 00kg, 700kg. number.

Q1: How to find suitable machine or complete beverage production line?

A1: Looking for beverage filling machine in www. Grandee machine. en. alibaba. com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team, providing good and after-sales service term, professional salesman terms

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee, and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing

For more information, please feel free to contact us to send inquiries!

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM