Main feature of this model:

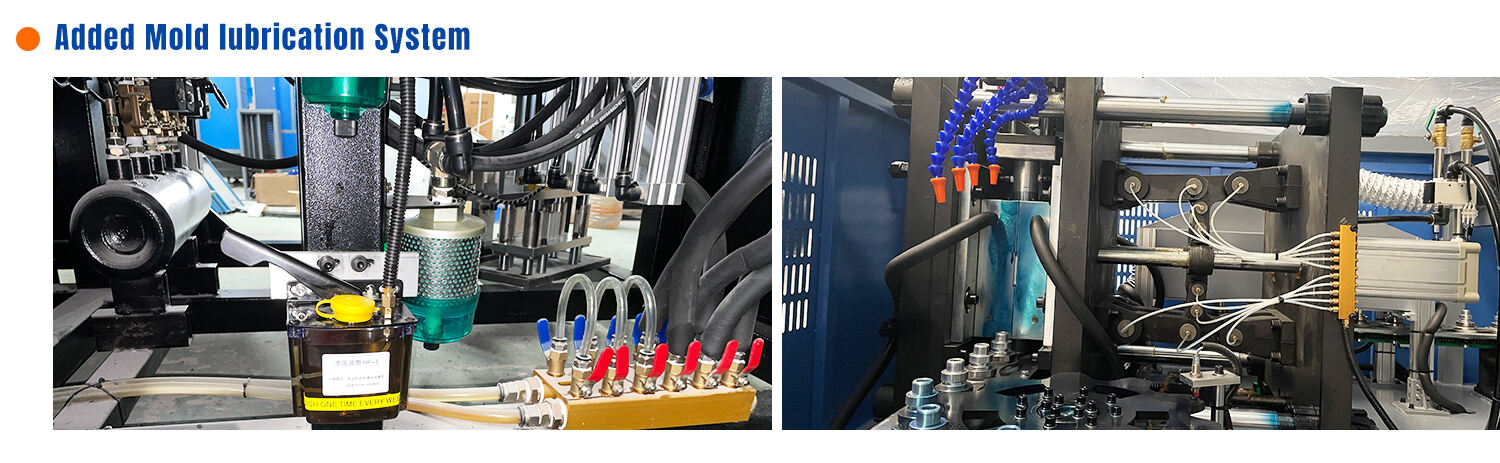

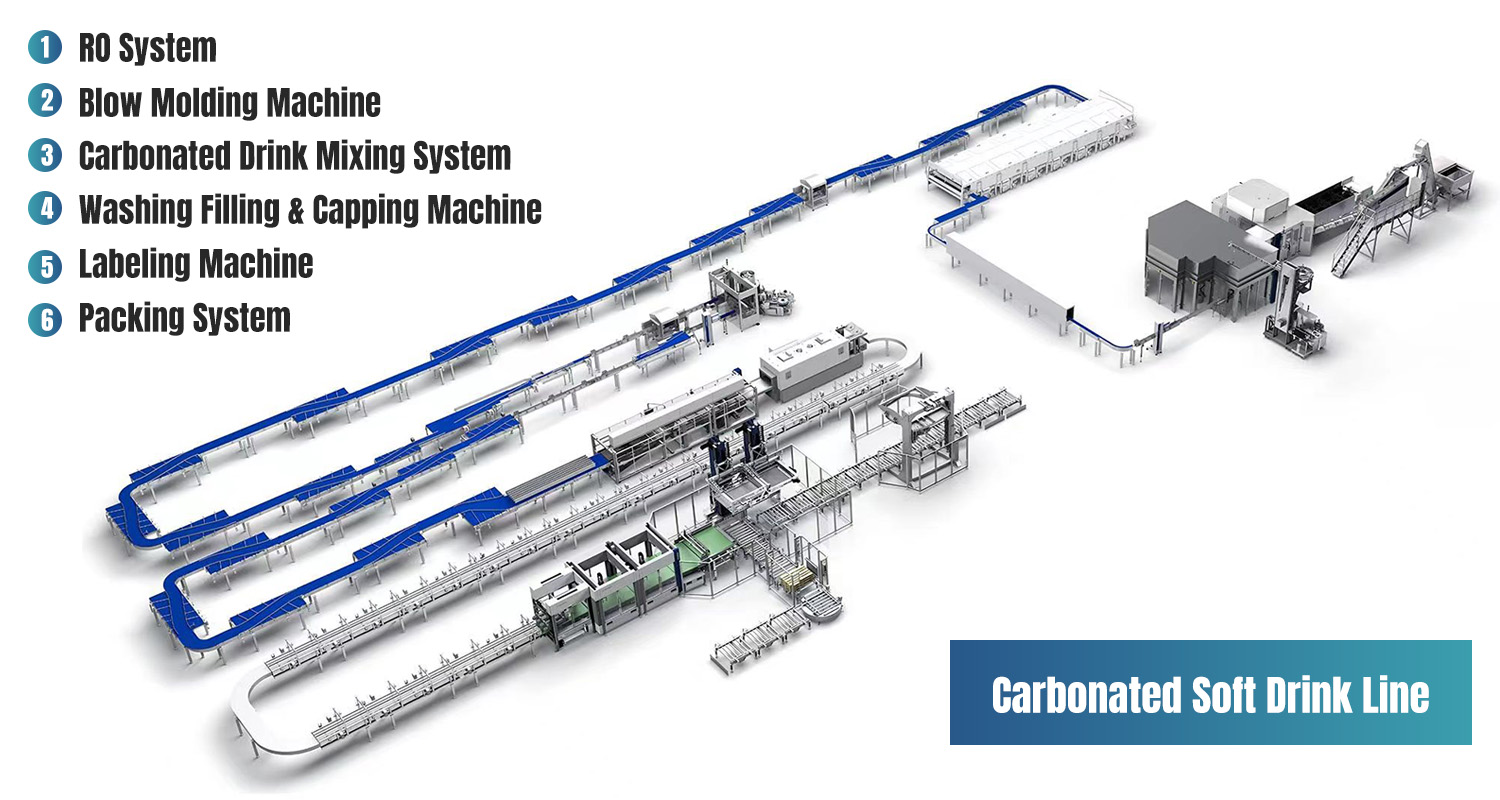

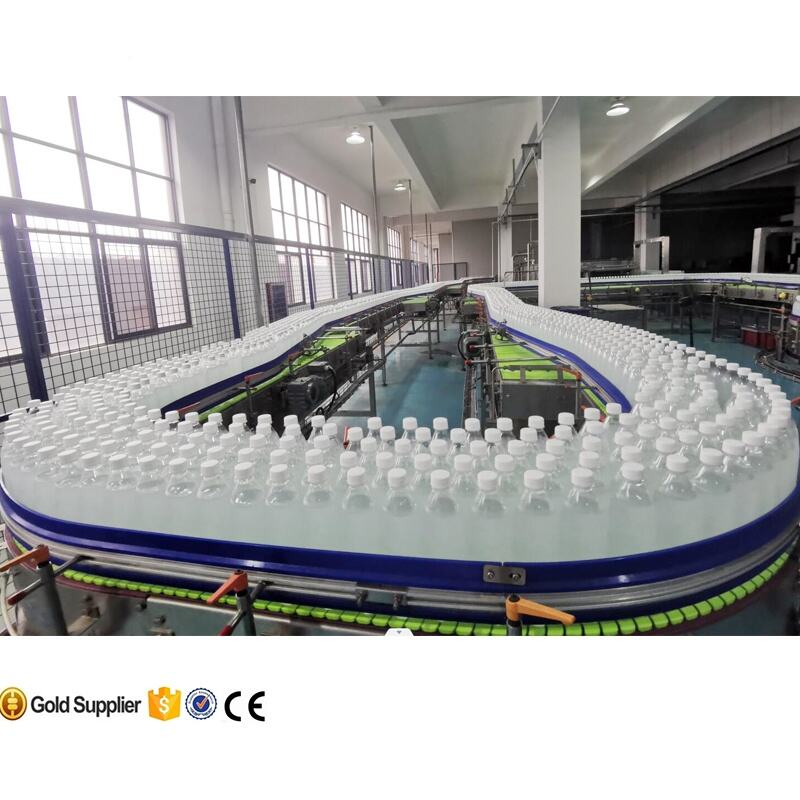

1. The man-machine interface is easy to operate. Everything is computerized, including temperature adjustment and preform distribution. 2. Preform unscrambling, loading, bottle handling and ordering are all operated by stainless steel manipulator automatically without a second contamination. 3. The circulating chilling water system can protect the bottle neck against deformation when the preform is being heated. 4. The homo thermic heater adopts auto reflection and closed loop adjusting system which have the power supplied constantly in proportion, not affected by the fluctuation of voltage. The conveying chain is short pitched and paratactic, which helps to realize slow heating and low power consumption. As a result, the preform can be heated evenly and easy to blow. 5. The positioned installation of molds makes it possible to change molds easily within 30 minutes. 6. All the critical parts we use for the machines, such as the electrical, hydraulic and pneumatic components, servo motor, etc, are famous branded parts imported from Japan, USA and Europe, which ensures the stability and long life of our equipments. 7. Servo motor controls the preform stepping motion; 8. Compact with 2 cavities, center distance 120 mm; 9. Newly high efficiency Ruby Heaters; 10. It is an ideal equipment to make different-shaped containers, such as mineral water bottle, beverage bottle, cosmetics bottle, medicine bottle, pesticide bottle, edible oil bottle, wine bottle, milk bottle, etc. With reasonable investment and high efficiency, it helps you raise production and save energy.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM