GRANDEE MACHINE

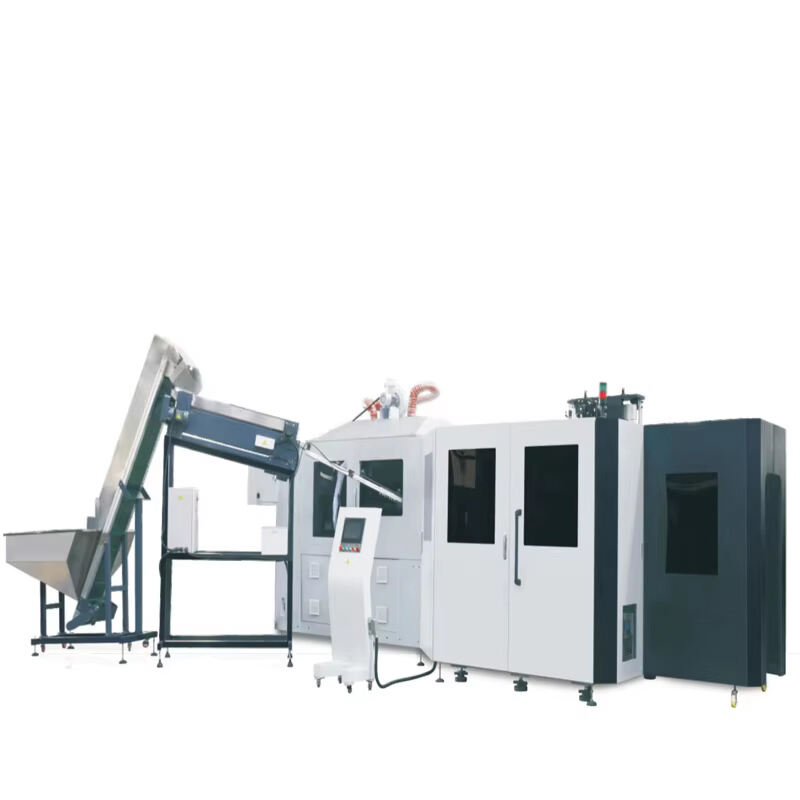

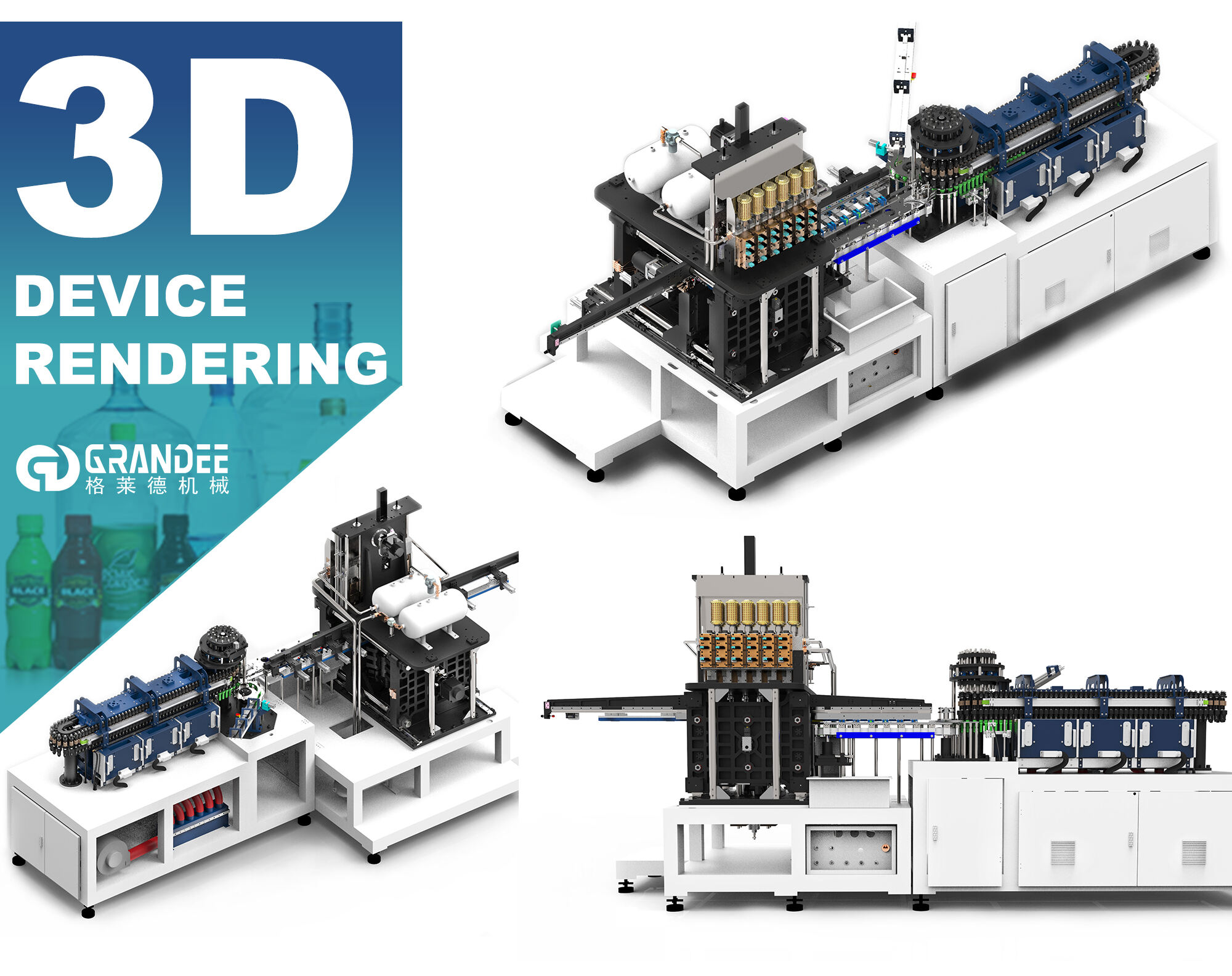

The top quality High Quality Full Automatic Pet Bottle Blow Molding Machine Price Blow Moulding Machine device may be the solution ideal organizations trying to find efficient and equipment dependable automate their container manufacturing procedure. This machine advanced designed to end in the manufacturing of top-notch animal bottles jars and containers hassle-free and simple

Very notable highlights of this blow molding device is its completely procedure automatic which somewhat decreases the necessity for handbook intervention through the manufacturing procedure. The GRANDEE MACHINE implies the apparatus could work non-stop and evening making certain your manufacturing line never ever operates far from containers also during top need durations time

Another standout function regarding the GRANDEE MACHINE's High Quality Full Automatic Pet Bottle Blow Molding Machine Price Blow Moulding Machine complete animal automated blow molding device is its high-level of modification. It really is made with a approach modular and therefore the person average could possibly be personalized to fit your certain manufacturing demands. This will ensure it is easy to attain the specified bottle size form and quality for the item

The device is made of top-notch materials and technology advanced level ensuring exceptional performance and durability. It employs a home sophisticated that guarantees consistent temperature circulation resulting in consistent and container manufacturing top-quality. Additionally it is made with an cooling advanced that facilitates faster and much more efficient cooling of this containers produced causing greater manufacturing prices

GRANDEE MACHINE's complete animal automated blow molding device can additionally be super easy to use and keep. It features interfaces that can easily be user-friendly easy intuitive settings that produce procedure simple. The equipment additionally is sold with step-by-step manuals and guides that provide helpful directions on how to run and keep maintaining the gear

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

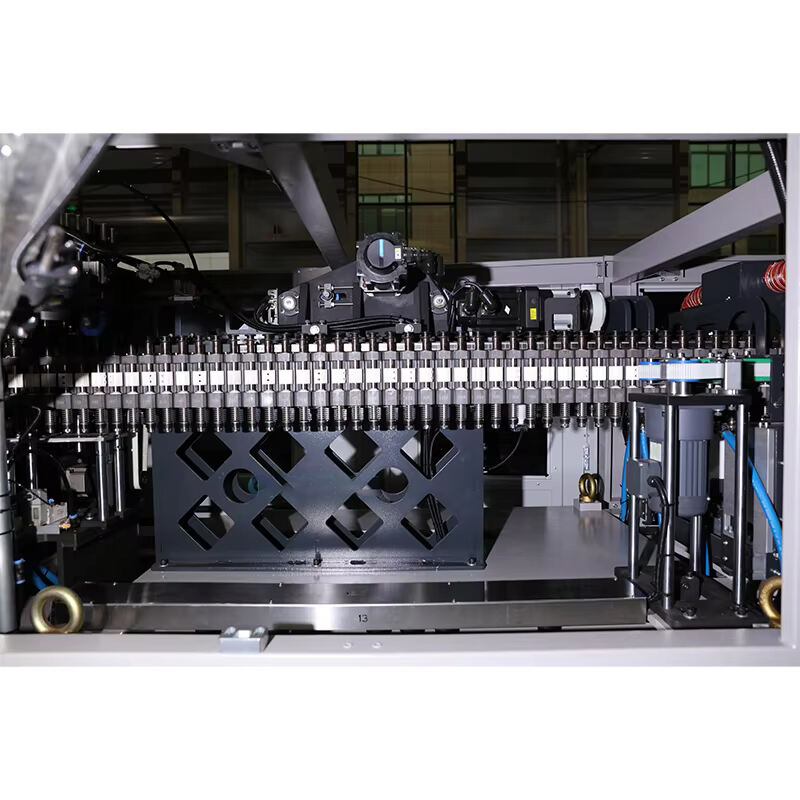

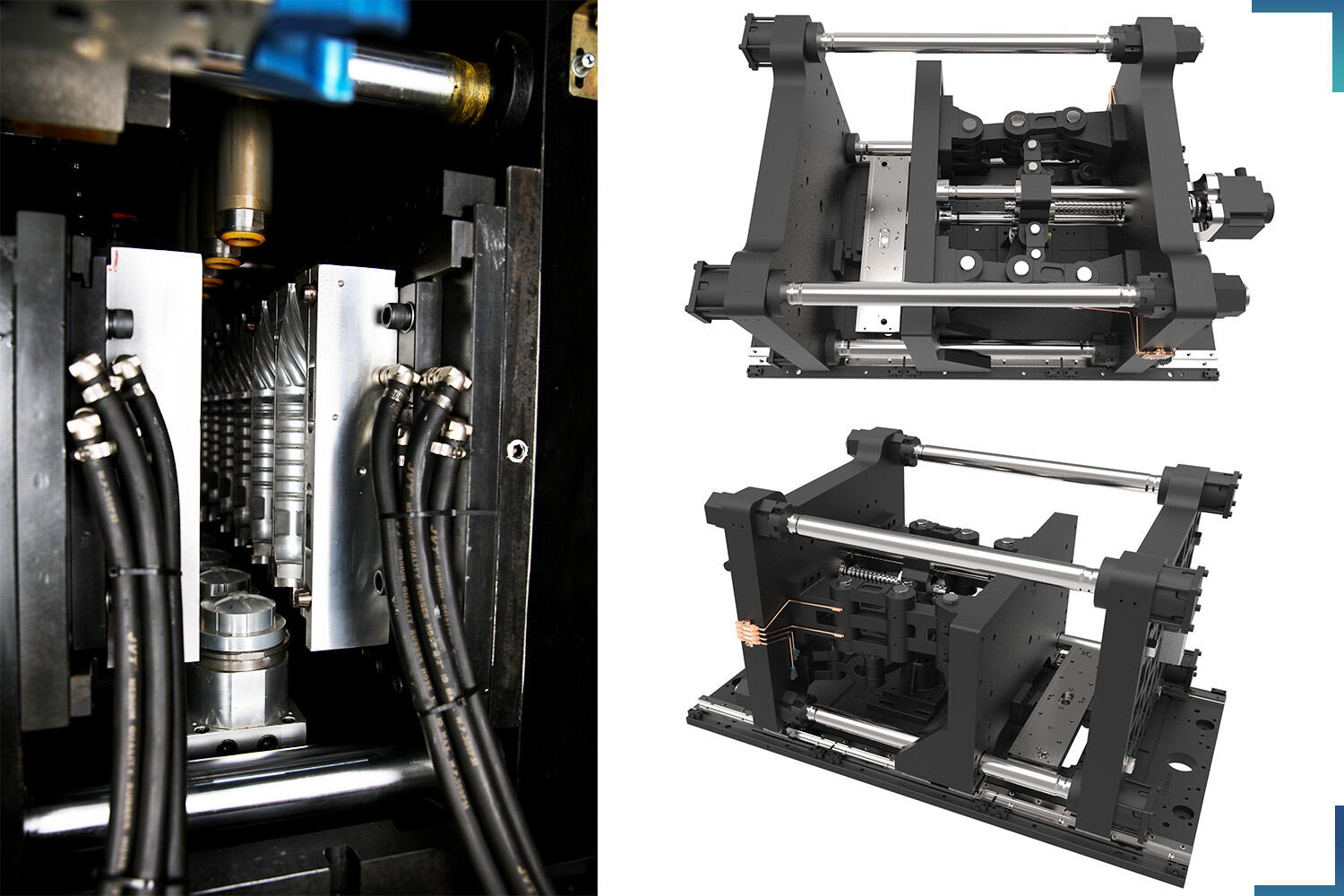

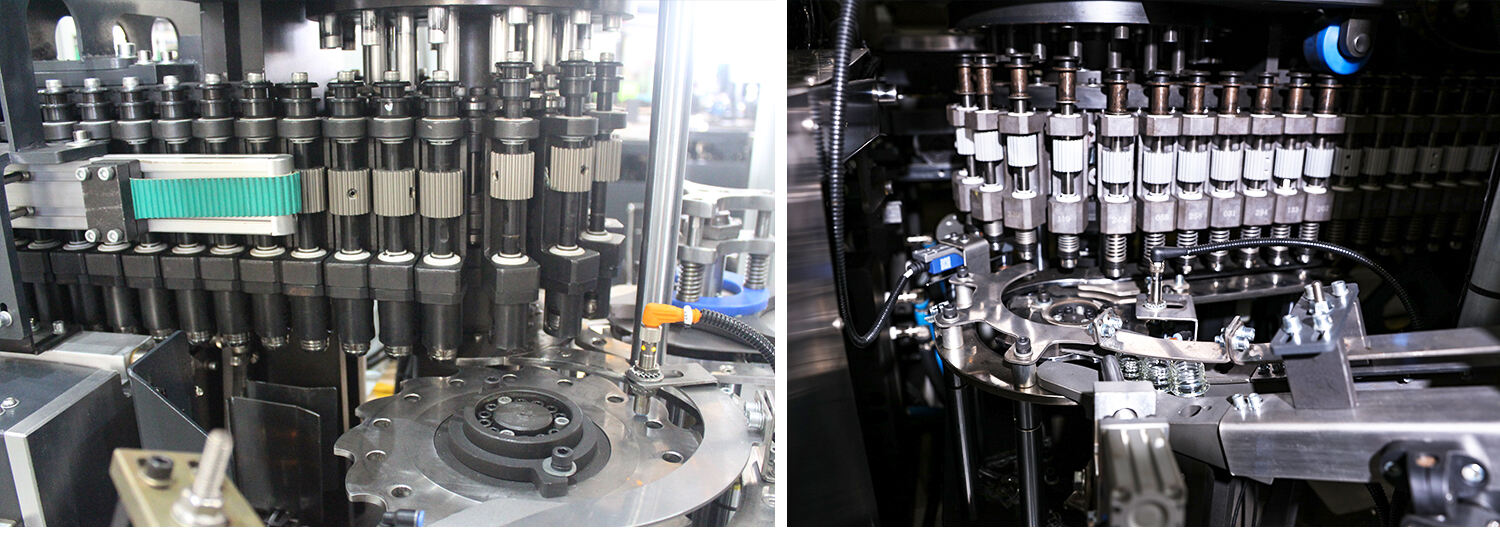

[1] Clamping Unit:

servo motor drives the reducer for clamping and opening, bottom cam system works together for mold open and close

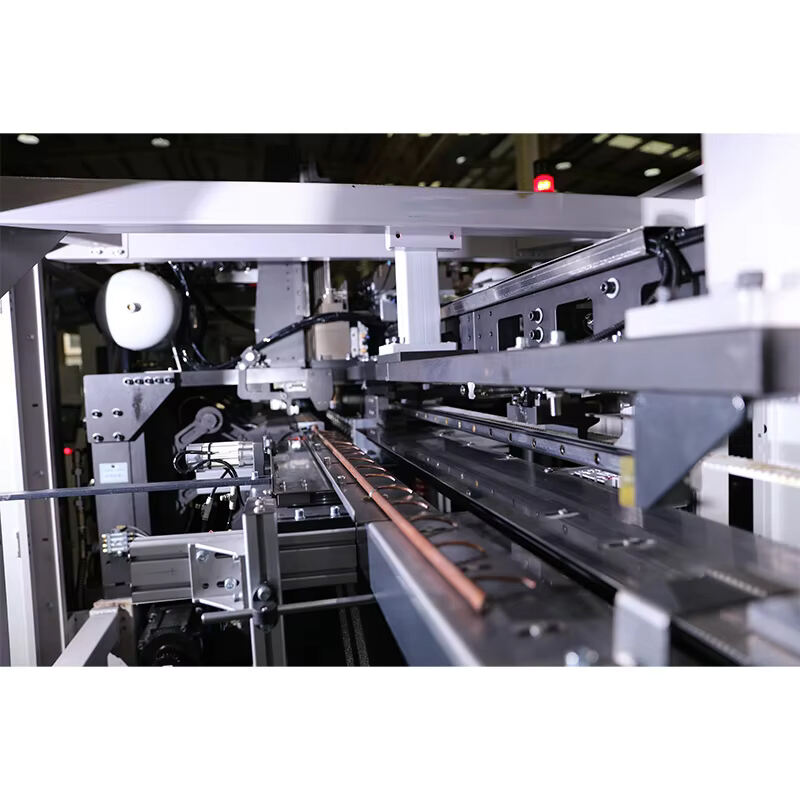

[2] Stretch unit:

servo motor driven, gear and rack system to achieve high speed

[3] Ceramic refection board system:

adopt Swiss ceramic reflection board to achieve high reflection efficiency, save power and high efficiency

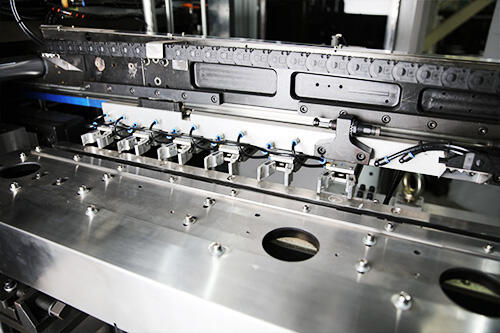

[4] Continuous splitting mechanism:

Adjust the pitch of the heated bottle blank (38.1mm) to the center distance required for blowing (114.3mm), achieving the goal of energy conservation. The clamping component includes at least 4 pneumatic fixtures with an opening angle of 180 degrees; The pneumatic fixture is driven by a cylinder to open the clamp block 180 degrees, so that when the pneumatic fixture is opened, the clamp block is parallel to the conveyor belt for transporting the bottle preform, ensuring that the pneumatic fixture does not need to move vertically when returning to pick up the bottle preform, but only needs to move horizontally. It not only saves time, simplifies the structure, but also reduces unnecessary shaking

[5] Combination high-pressure blowing valve:

The valve body operates sensitively and has a fast response speed, with a short blowing time cycle, increasing production capacity and reducing energy consumption.

[6] Star wheel preform feeding system:

a linked type preform feeding star wheel disc, with the oven and star wheel disc linked, reliable and stable one-on-one preform feeding, ensuring that there is no omission of preforms

[7] Air intake system:

The air source cooling water is centralized at the inlet, avoiding disorderly external pipelines. The entire set adopts Japanese SMC components, making the air source more stable

|

Model

|

Unit

|

GD-8II

|

|

|

|

|

|

Clamping System

|

Number of cavity

|

cavities

|

8

|

|

|

|

|

|

mold stroke

|

mm

|

0-130

|

|

|

|

|

(stretch stroke

|

mm

|

340

|

|

|

|

|

Bottom stroke

|

mm

|

50

|

|

|

|

|

Cavity pitch

|

mm

|

114.3

|

|

|

|

|

heating pitch

|

mm

|

50.8

|

|

|

|

|

Number of holder

|

PCS

|

128

|

|

|

|

|

Container

|

Max. container volume

|

ltr

|

1.5

|

|

|

|

|

|

Max. neck diameter

|

mm

|

30/38

|

|

|

|

|

Max. preform height

|

mm

|

120

|

|

|

|

|

Max. container diameter

|

mm

|

95

|

|

|

|

|

Max. container height

|

mm

|

320

|

|

|

|

|

theoretical output

|

|

B.P.H

|

12000-14000

|

|

|

|

|

Electrical System

|

heating oven

|

UNITS

|

8

|

|

|

|

|

|

box*channel

|

layer

|

10

|

|

|

|

|

Number of lamp

|

pcs

|

80

|

|

|

|

|

heating power

|

KW

|

96

|

|

|

|

|

AVERAGE POWER

|

KW

|

38

|

|

|

|

|

installed power

|

KW

|

108

|

|

|

|

|

voltage

|

Voltage

|

220v/380V/3phase

|

|

|

|

|

Air System

|

operating pressure

|

kg/cm2

|

7

|

|

|

|

|

|

blowing pressure

|

mpa

|

2.5-3.5

|

|

|

|

|

high pressure air consuming

|

L/min

|

8

|

|

|

|

|

Chiller System

|

temperature

|

°C

|

10-15

|

|

|

|

|

|

pressure

|

Mpa

|

0.4

|

|

|

|

|

flow rate

|

L/min

|

80

|

|

|

|

|

heating power

|

HP

|

10

|

|

|

|

|

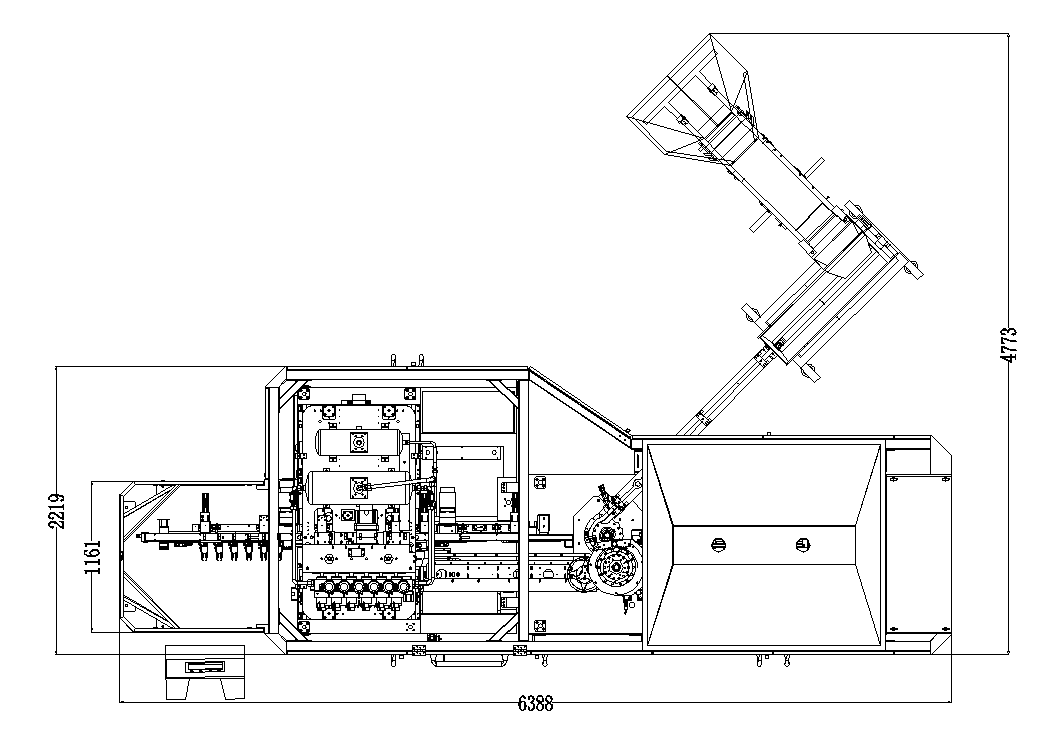

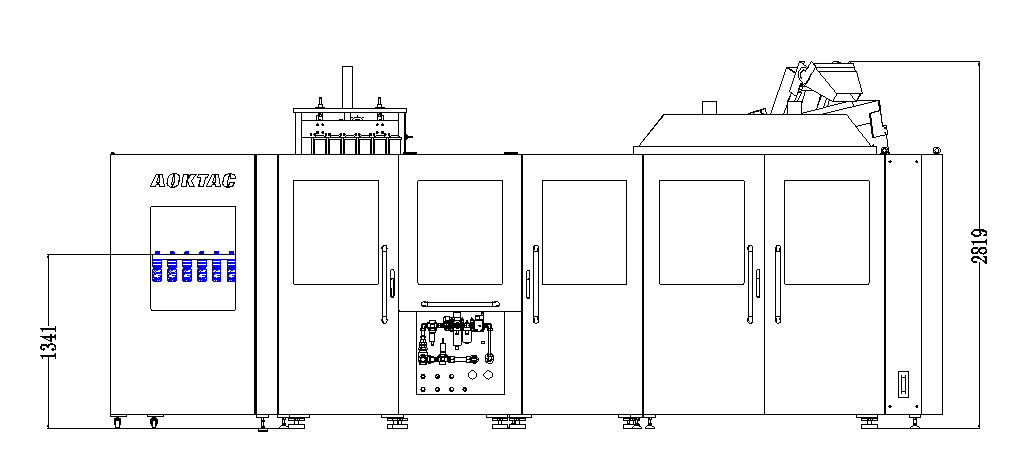

Machine

|

machine dimension

|

M

|

7.2*2.1*2.8(machine)

|

|

|

|

|

|

|

|

2.5*2.0*2.5(machine)

|

|

machine weight

|

KG

|

10000

|

|

|

|

Fruit juice filling machine

One stage or Second stage R.O. Water treatment system

Raw Water Tank→ Raw Water Pump→ Quartz Sand Filter→Activated Carbon Filter→ 5 Micron Filter→ 1 Micron Filter→High Pressure Pump→Primary Reverse Osmosis Device→Intermediate Water Tank→ Booster Pump→ (Secondary High Pressure Pump→Secondary Reverse Osmosis Device) → Ozone Mixer→Pure Water Pump→ Pure Water Tank→ External Supply Pump→ Titanium Tube Filter→ External Supply→ To Filling Machine

Automatic OPP BOPP hot melt Glue labeling machine

Automatic BOPP labeling machine is widely suitable for different material of containers and labels. The cost of each label is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is one of the most economical models to make mass production and integrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, like changing the label is only needed to change the PLC program, the products concept that the equipment is used for users and considered for users is embodied in everywhere

Automatic PVC PE Sleeve Shrink Labeling Machine

This fully automatic sleeve labeling machine is suitable for various kinds of bottles, like round bottles, square bottles, oval bottles, etc. This machine can automatically feed and cut film, and it can sleeve labels precisely, greatly saving labor and improving work efficiency. The machine can be widely used for beverage bottles, cosmetic bottles, shampoo bottles, etc

Operating Principle Of Packaging Machine

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping

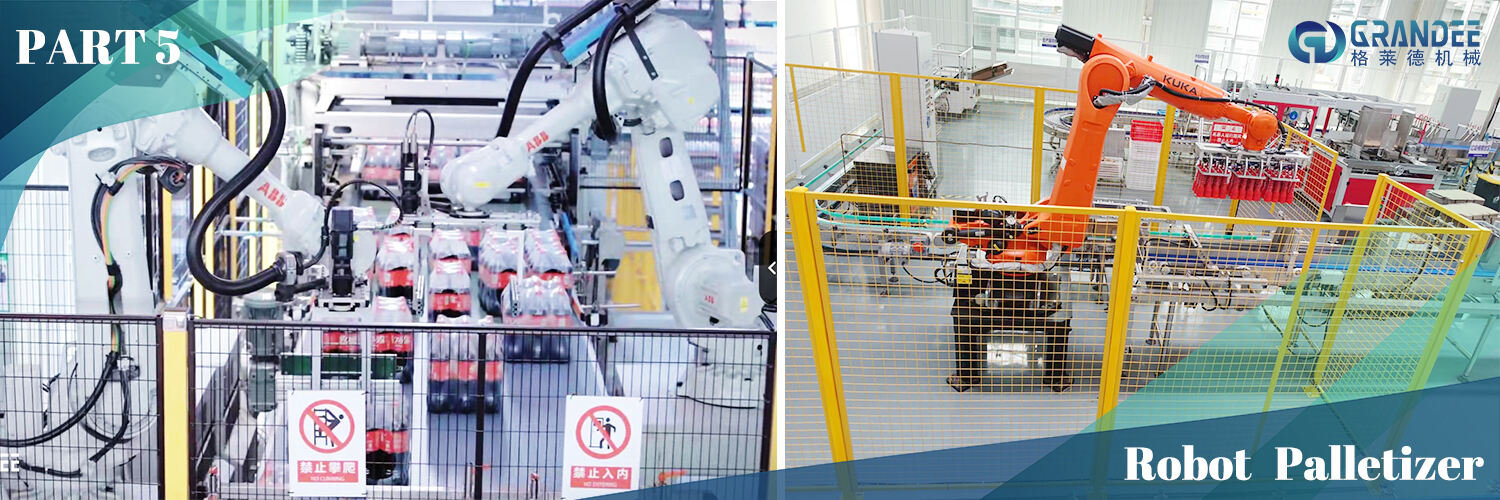

Robot Palletizer

Which contribute to the robot-ization of the pallet-izing system has a compact body and a high throughput It is suitable for packing bottled drinking water, juice, carbonated soft drinks etc. with production capacity up to 520layer/h. Suitable robot models can be selected according to the work pieces. Payload 110kg,140kg, 185kg,315kg, 500kg, 700kg

|

NO

|

Item

|

Data

|

|

1

|

Power

|

15KW(will be changed according to different models

|

|

2

|

Robot

|

KUKA, ABB, NACHI

|

|

3

|

Max load per pallet

|

1.6tons (will be changed according to different models

|

|

4

|

Pallet size

|

1200x1000mm(can be customized according to customer requirements

|

|

5

|

Palletizing speed

|

10-80packs/min(the pallet-izing speed is related to the size of the pallet and the grouping form of each layer

|

|

6

|

Pallet material

|

Wood or plastic

|

|

7

|

Overall size

|

(L)8000MMx(W)4500MMx(H)3000MM(will be changed according to different models

|

|

8

|

Machine weight

|

4500KG(will be changed according to different models

|

Q1: How to find suitable machine or complete beverage production line

A1: Looking for beverage filling machine in www.grandeemachine.en.alibaba.com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for

Q2: Are you a trading company or a manufactory

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team, providing good and after-sales service term, professional salesman terms

Q3: Do you have technical support after we purchased your machines

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems

Q4: If you buy our machines, can you offer us wear-out spare parts

A4: We provide our high quality machine 2 years guarantee, and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM