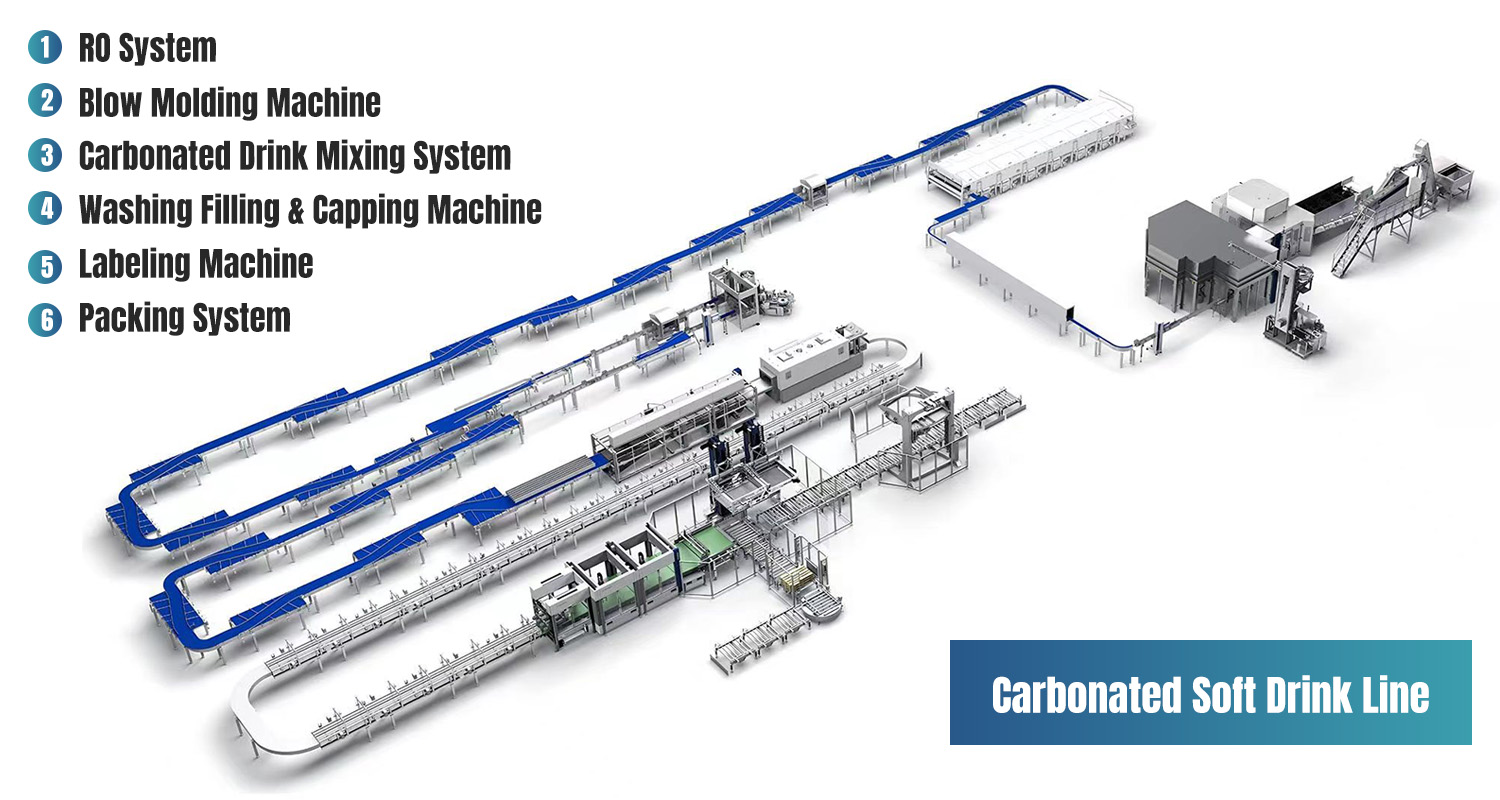

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

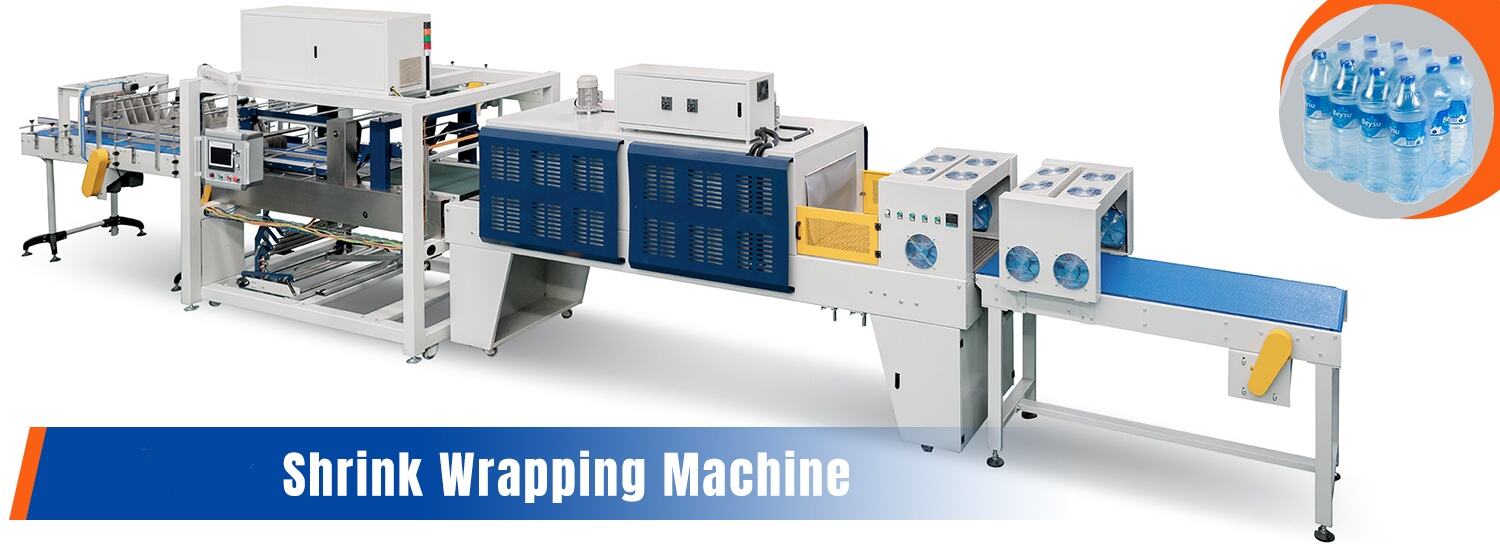

Operating Principle Of Packaging Machine

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping.

|

|

|

|

|

|

Power Supply

|

AC 380V/60HZ

|

Weight

|

5500KG

|

|

|

|

|

Operating Power

|

55KW

|

Maximum Packaging Size

|

450×450×340(H)mm

|

|

|

|

|

Working Pressure

|

0.6~0.8Mpa

|

Film Cutter Length

|

600mm

|

|

|

|

|

Gas consumption

|

80NL/min-100NL/min

|

Shrink Time

|

0-6S(Depends on speed and site conditions)

|

|

|

|

|

Heat Shrinkable Film

|

PE( Color Film)

|

Maximum Production Speed

|

20-25 Pack/minute(Determined according to package size and packaging specifications)

|

|

|

|

|

Working Noise

|

≤65

|

Number of bottles per package (round or square)

|

|

|

|

|

Packaging Film Width

|

≤600mm

|

4 columns 4 x 6 4 x5 applicable bottle size

|

4 x 4 Ф 40 - Ф 70 mm

|

|

|

|

|

Packaging Film Thickness

|

0.03~0.15mm

|

3 columns 3 x 3 applicable bottle size

|

3 x 4 Ф 70 - Ф 98 mm

|

|

|

|

|

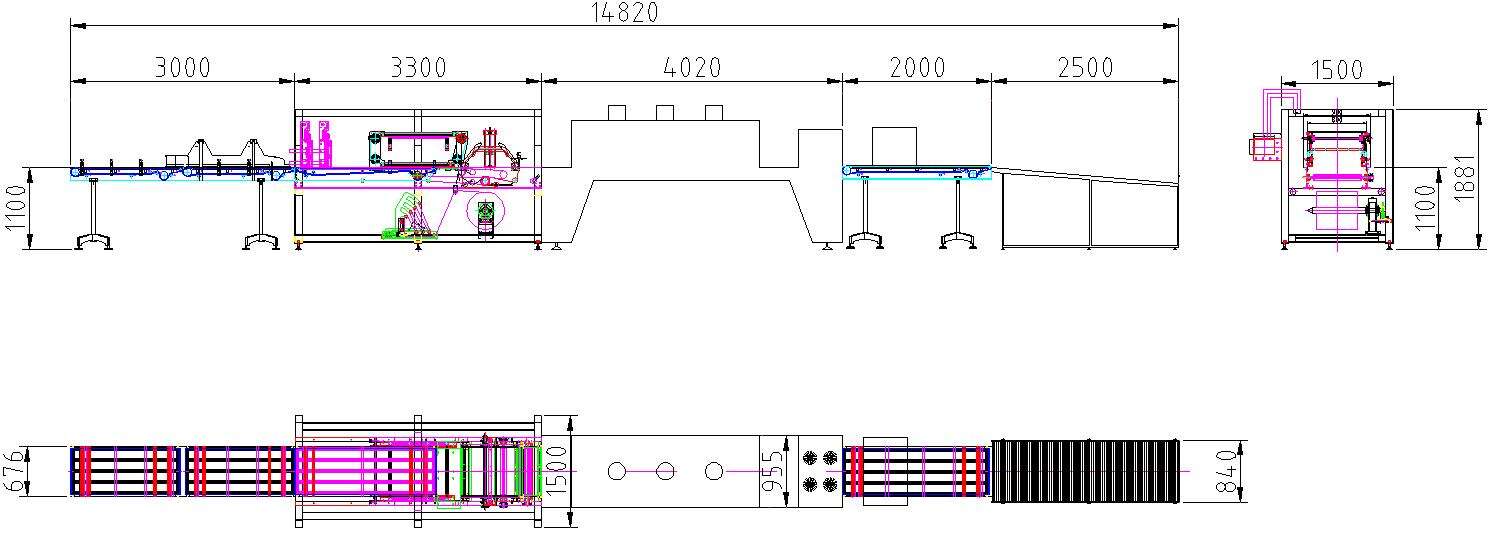

Level Of Feeding Conveyor Belt

|

1150±50mm

|

2 columns 2 x 3 bottle diameter

|

2 x 4 Ф 98 mm

|

|

|

|

|

package style: Sleeve Style

|

Cuff Style

|

1 column 1 x 2 x 1 applicable bottle diameter

|

1 x Ф140 mm

|

|

|

|

The Machine Features And Advantages

4.1.Selecting universal brand-name components, uniform specifications, and random interchangeability.

4.2.The PLC programmable control system is adopted to ensure the accuracy and stability of the packaging process control.The shrinking machine adopts the latest thermal cycle treatment technology to reduce energy consumption. Improve the utilization rate of hot air, and the conveying speed can be adjusted by frequency conversion to achieve a good packaging effect.

4.3.Touch screen control makes the device action control enter a high-precision and intelligent state. All actions are monitored, various alarms and PC status are displayed on the touch screen, which makes the equipment operation safer and more reliable. It can be operated in a single step, which is convenient forde bugging and maintenance. The equipment is equipped with an automatic alarm device to further improve the safety and reliability of the equipment.

4.4.The pneumatic components adopt the brand of Taiwan Airtac.

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

Q1: How to find suitable machine or complete beverage production line?

A1: Looking for beverage filling machine in www.grandeemachine.en.alibaba.com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for.

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team , providing good and after-sales service term , professional salesman terms .

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee , and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

GRANDEE MACHINE

Introducing the Fully Automatic Pure Bottle PE Film Shrink Tunnel Wrapping Packing Machine Plant an innovative solution designed to streamline your packaging process and boost efficiency in your manufacturing facility.

Developed to last, with durable materials and state-of-the-art technology that ensures reliable performance and constant outcomes. Powered by advanced automation, this machine is completely automatic, requiring minimal human intervention and offering procedure is hands-free.

Capable of wrapping and packing a range is wide of, making it well suited for use in industries such as food and drink, pharmaceuticals, cosmetics, along with other consumer goods. This GRANDEE MACHINE machine can manage the job with ease whether you will need to bundle bottles, cans, jars, or other containers.

Among the key features is its use of pure bottle PE film, which provides protection is superior your products. This packaging is advanced offers excellent resistance to dampness, dust, and other ecological factors that could harm your products during shipping.

incorporates a shrink tunnel system is wrapping which uses heat to shrink the packaging film tightly around your products or services. This ensures a secure and fit is snug reducing the risk of damage during transportation. The procedure is efficient and fast, using the device capable of wrapping and packing up to 120 products per minute.

Designed to be easy to utilize and maintain in addition to its higher-level packaging technology. with an interface is intuitive users can very quickly and simply put up the machine to meet their specific packaging needs. and with automatic maintenance and cleaning functions, the machine requires minimal upkeep, reducing downtime and productivity is enhancing.

Overall, if you're looking for a reliable and efficient way to package your products, the Fully Automatic Pure Bottle PE Film Shrink Tunnel Wrapping Packing Machine Plant from GRANDEE MACHINE is an excellent choice. with its advanced technology, durable construction, and user-friendly design, this machine is sure to streamline your packaging process and improve your bottom line.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM