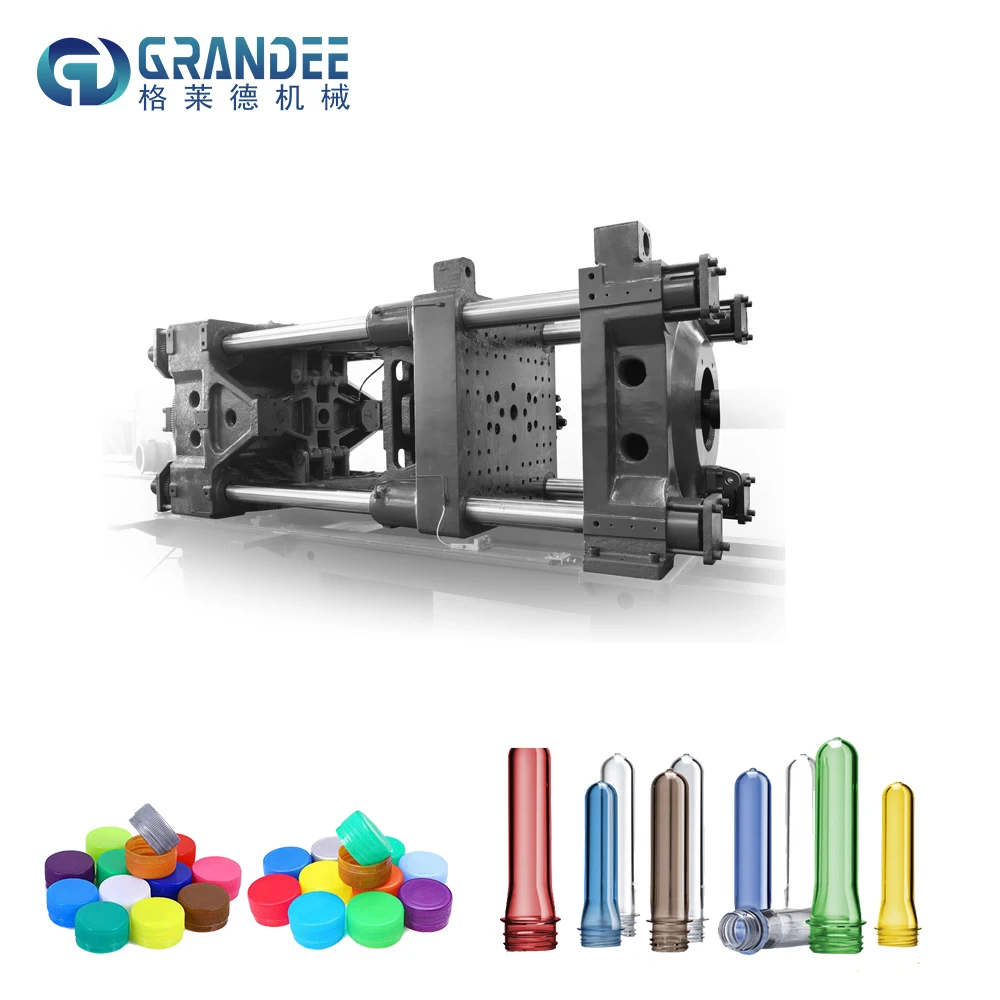

High Efficiency Energy Saving Injection Molding Machine adopts proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock, the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close - loop PID tem - perature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators ' s safety

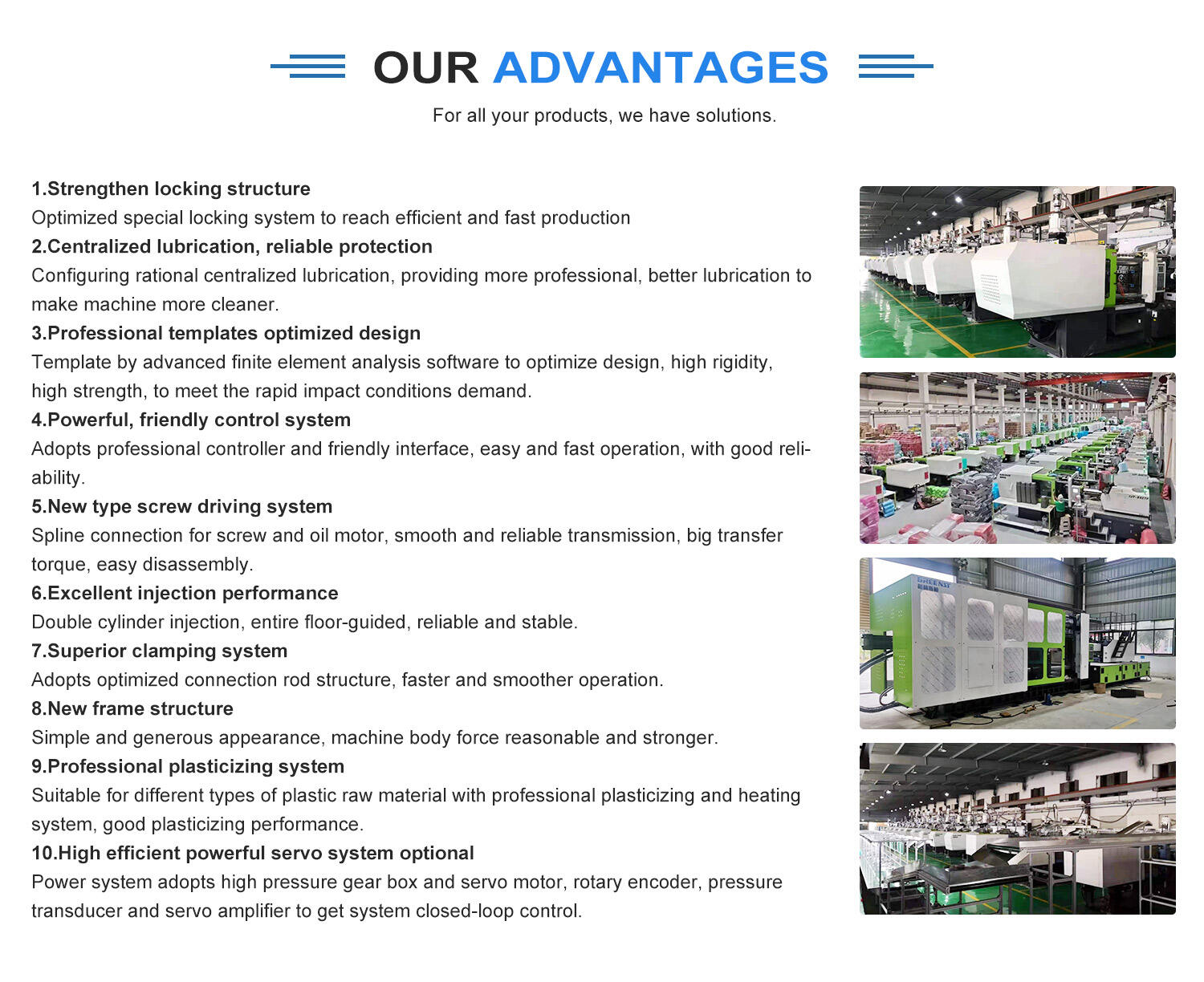

OUR ADVANTAGES1. Strengthen locking structure Optimized special locking system to reach efficient and fast production

2. Centralized lubrication, reliable protection Configuring rational centralized lubrication, providing more professional, better lubrication to make machine more cleaner.

3. Professional templates optimized design Template by advanced finite element analysis software to optimize design, high rigidity, high strength, to meet the rapid impact conditions demand.

4. Powerful, friendly control system Adopts professional controller and friendly interface, easy and fast operation, with good reli - ability

5. New type screw driving system Spline connection for screw and oil motor, smooth and reliable transmission, big transfer torque, easy disassembly.

6. Excellent injection performance Double cylinder injection, entire floor - guided, reliable and stable.

7. Superior clamping system Adopts optimized connection rod structure, faster and smoother operation.

8. New frame structure Simple and generous appearance, machine body force reasonable and stronger.

9. Professional plasticizing system Suitable for different types of plastic raw material with professional plasticizing and heating system, good plasticizing performance.

10. High efficient powerful servo system optional Power system adopts high pressure gear box and servo motor, rotary encoder, pressure transducer and servo amplifier to get system closed - loop control

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM