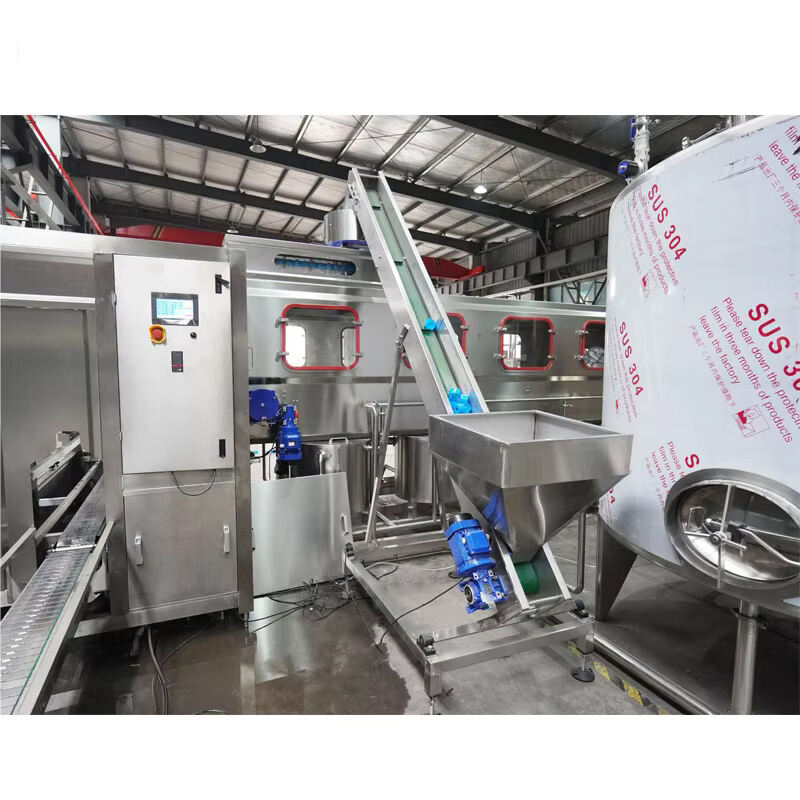

Presenting, the Full Automatic Complete Turnkey 5 Gallon Bottle Filling Machine 5 Gallon Barrel Pure Water Production Line, proudly presented by GRANDEE MACHINE. This top-of-the-line product was meant to offer hassle-free and efficient manufacturing of pure, top-notch water in 5-gallon containers.

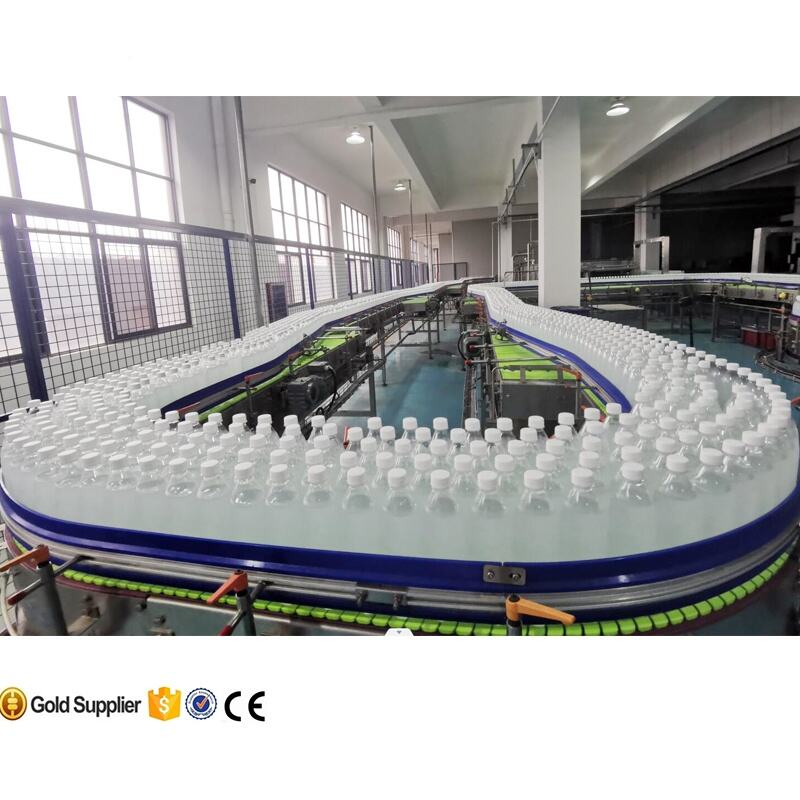

This is perfect for busy production environment where time is important with its completely automatic features. This machine is not hard to utilize, making it perfect for novice and expert operators. It guarantees uniformity and high accuracy on each container, with zero mistakes in the manufacturing procedure.

The Full Automatic Complete Turnkey 5 Gallon Bottle Filling Machine includes a number of advanced features, including a complete rinsing, automatic filling, and capping system. This offers a great production of up to 900 barrels each hour, permitting you to complete high-volume of tasks in a small period of time compared to old-fashioned techniques.

Furthermore, this product was established to minimize waste. The equipment's easy design makes upkeep and cleansing a breeze that makes it easy to retain in top working condition. The unit was manufactured from top-quality materials to ensure its durability and, making it a long-lasting investment.

The Full Automatic Complete Turnkey 5 Gallon Bottle Filling device from GRANDEE MACHINE was created for various sources, including different minerals and other solutions. The product was made of a top-quality water system, ensuring the last item is without any impurities

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

5 Gallon Mineral Pure Water Filling Production Machine

The 5 gallon water filling line specially for 3-5 gallons barreled drinking water, with type QGF-150, QGF-200, QGF-300, QGF-450, QGF-600, QGF-900, QGF-1200. It integrated bottle washing, filling and capping into one unit, in order to achieve the purpose of washing and sterilizing. The washing machine uses multi-washing liquid spray and disinfectant spray, the disinfectant can be used circularly. The capping machine can be cap barrel automatically. The line equips with water spraying device in order to ensure those caps sterile and clean, it also can automatically carry out barrel, washing, sterilizing, filling, capping, counting and products discharging, with complete function, modern design and high degree of automation, It is a new kind of barreled water auto producing line, which integrates mechanism, electricity and pneumatics technologies together

Automatic Decapping Machine

Decapping machine can be used alone, or whole production line. The cap-pulling head is mainly composed of cap pulling claw, cylinder, and other components. The cap-pulling head can be adjusted up and down, and the cap-pulling claw can be fine-tuned. It does not hurt the bottle mouth and has strong applicability to different bottle mouths. The host machine is controlled by PLC

Leakage Tester

Automatic 5 gallon bottle Leaking Detector is a professional equipment to check leakage. With inline design, empty 5 gallon bottle is fed into testing compressed air continuously. After gas filling, pressure keeping, pressure testing, qualified bottle will be sent to next process, the damaged barrels will be kicked out of conveyor

Automatic rotary outer brushing machine

It can wash bottle neck, bottle body, bottle bottom and other parts, the bottle in the machine to complete the revolution around the main shaft and its own autobiography, to achieve a full range of cleaning, cleaning water after washing. The machine is made of excellent stainless steel with the advantage of easily-rinsing and corruption-resistance. The main electrical elements adopt the products with brands of SIEMENS and OMRON. Pneumatic elements adopt the products with brand of AIRTAC

High pressure inside and outside brushing machine

1. high pressure nozzle clean inside, Brusher clean outside, 2. The machine is special 5 gallons brush barrel machine, the main material is 304, beautiful appearance, reasonable structure, 3. convenient operation, automatic control, the main components is import, internal and external body brush, reduce the user's using area, it is ideal for 5 gallons filling machine equipment

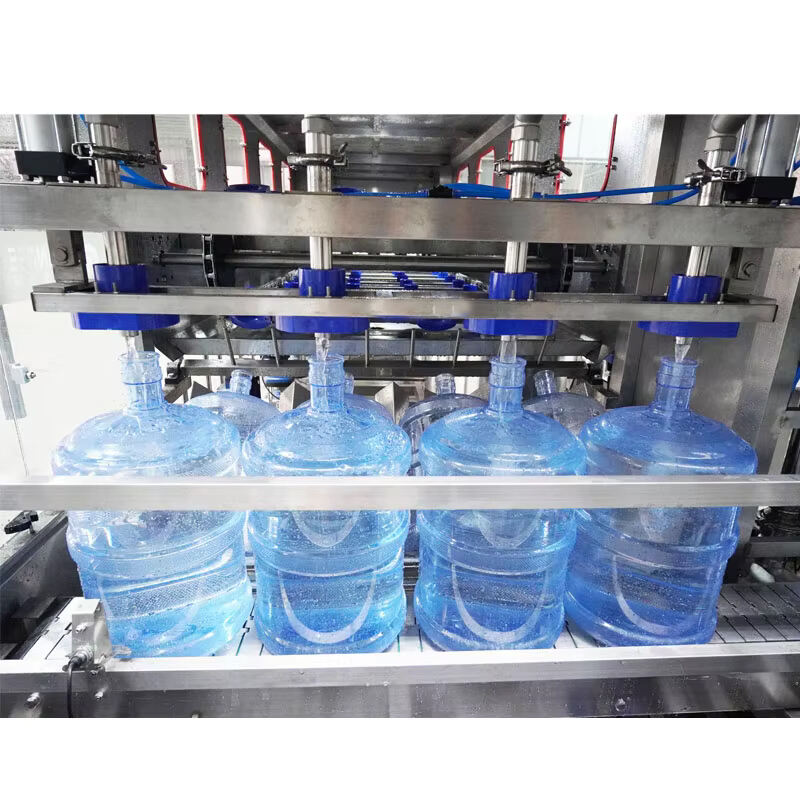

5 gallon water filling machine

QGF series 5 gallon filling machine is designed for producing 5 gallon barrel drinking water. This machine is consisted of Rinser, filler and capper. The Rinser has several sprays which can be used as for both clean water rinsing and disinfectant

rinsing. The disinfectant can be recycled. The machine also has automatic capping device, and cap rinsing device. The

whole production line can automatic feeding barrel, rinsing, sterilizing, filling, capping, counting and output

Automatic 5 gallon cap seal shrink labeling machine

Equipment production efficiency: 100bottles/min, single shrink labels for the tray, microcomputer automatic control; Automatic detection, automatic positioning; In the rapid and energy saving, to cut off the position precision

Automatic palletizer

1. The best choice for increasing production and efficiency 2. Put the packaged buckets on the pallet according to a certain arrangement code for automatic stacking, which can be stacked in multiple layers and then pushed out to facilitate the forklift to transport to the warehouse for storage

|

Model

|

|

QGF-200

|

QGF-300

|

|

|

QGF-900

|

|

|

|

|

|

|

|

|

Capacity(500ml/BPH)

|

150

|

200

|

300

|

450

|

600

|

900

|

1200

|

|

|

|

|

|

|

|

Suitable bottle shape and size

|

|

|

|

|

|

|

|

|

Compressed air pressure

|

|

|

|

|

|

|

|

|

Bottle washing medium

|

|

|

|

|

|

|

|

|

Washing pressure

|

|

|

|

|

|

|

|

|

Main motor

|

1.5

|

2.2

|

2.2

|

2.2

|

4.5

|

5.5

|

7.5

|

|

|

|

|

|

|

|

Dimension mm

|

2900*1000*1800

|

3200*1200*2300

|

3900*1200*2300

|

5000*1500*2300

|

6200*18*2300

|

7970*1800*2700

|

10780*2000*2700

|

|

|

|

|

|

|

|

Weight KG

|

500

|

1500

|

3000

|

3500

|

4500

|

5500

|

7500

|

|

|

|

|

|

|

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

One stage or Second stage R.O. Water treatment system

Raw Water Tank→ Raw Water Pump→ Quartz Sand Filter→Activated Carbon Filter→ 5 Micron Filter→ 1 Micron Filter→High Pressure Pump→Primary Reverse Osmosis Device→Intermediate Water Tank→ Booster Pump→ (Secondary High Pressure Pump→Secondary Reverse Osmosis Device) → Ozone Mixer→Pure Water Pump→ Pure Water Tank→ External Supply Pump→ Titanium Tube Filter→ External Supply→ To Filling Machine

Automatic OPP BOPP hot melt Glue labeling machine

Automatic BOPP labeling machine is widely suitable for different material of containers and labels. The cost of each label is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is one of the most economical models to make mass production and integrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, like changing the label is only needed to change the PLC program, the products concept that the equipment is used for users and considered for users is embodied in everywhere

Automatic PVC PE Sleeve Shrink Labeling Machine

This fully automatic sleeve labeling machine is suitable for various kinds of bottles, like round bottles, square bottles, oval bottles, etc. This machine can automatically feed and cut film, and it can sleeve labels precisely, greatly saving labor and improving work efficiency. The machine can be widely used for beverage bottles, cosmetic bottles, shampoo bottles, etc

Operating Principle Of Packaging Machine

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping

Company Profile

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line, can filling and sealing line, complete blowing labeling and packaging system

We have laser cutting, CNC machining centers, and other various processing equipment to provide customers with precise and reliable products. The ERP system provides an important resource integration path for production management and ensures production and delivery cycles

Q1: How to find suitable machine or complete beverage production line

A1: Looking for beverage filling machine in www.grandeemachine.en.alibaba.com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for

Q2: Are you a trading company or a manufactory

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team, providing good and after-sales service term, professional salesman terms

Q3: Do you have technical support after we purchased your machines

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems

Q4: If you buy our machines, can you offer us wear-out spare parts

A4: We provide our high quality machine 2 years guarantee, and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing

For more information, please feel free to contact us to send inquiries!

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM