GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

Juice / Milk / Aseptic Cold Filling Machine RXGF32-32-8

Aseptic cold juice filling equipment adopts bottle neck holding transmission technology to realize fully automatic bottle rinsing, cold juice filling, carbonated filling and cap screwing. It employs single cavity plunger type of fixing filling volume technique. It is equipped with negative pressure filling valves, so that the liquid level is always stable. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation etc

Washing part

Into bottle way is air conveyor direct connection with bottle dial

All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean 304/316

Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

304/316 stainless steel washing pump make the machine more durable

Filling part

304/316 Stainless steel high precision filling nozzle Filling volume adjustable in fine rank, same liquid level after filling All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

304/316 stainless steel filling pump

Efficient spray nozzle rinse thoroughly and save water for flushing

Capping part

Place and capping system with aluminum foil sealing part, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping All 304/316 stainless steel construction No bottle no capping

Automatic stop when lack of bottle

Capping effect is stable and reliable, Defective rate ≤0.2%

|

Model

|

RXGF

14-12-5

|

RXGF

18-18-6

|

RXGF

24-24-8

|

RXGF

32-32-8

|

RXGF

40-40-12

|

RXGF

50-50-12

|

|

Capacity (500ml)

|

2000-3000

|

3000-5000

|

5000-7000

|

8000-9000

|

10000-12000

|

12000-14000

|

|

Suitable bottle shapes

|

PET circular

|

|

Bottle diameter

|

50-115mm

|

|

Bottle height

|

160-320mm

|

|

Filling type

|

Isobaric filling

|

|

Filling pressure

|

<0.4MPa

|

|

Rinsing water pressure

|

>0.06MPa <0.2MPa

|

|

Application

|

Carbonated soft drink bottling line

|

|

Total power

|

4.4kw

|

5.2kw

|

6.2kw

|

7.5kw

|

8.2kw

|

11kw

|

|

Overall dimensions

|

2.5*1.9m

|

2.8*1.9m

|

3.2*2.2m

|

3.4*2.5m

|

4.8*2.3m

|

5.5*3.3m

|

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

|

Weight

|

3000kg

|

4500kg

|

6000kg

|

8500kg

|

10000kg

|

11000kg

|

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

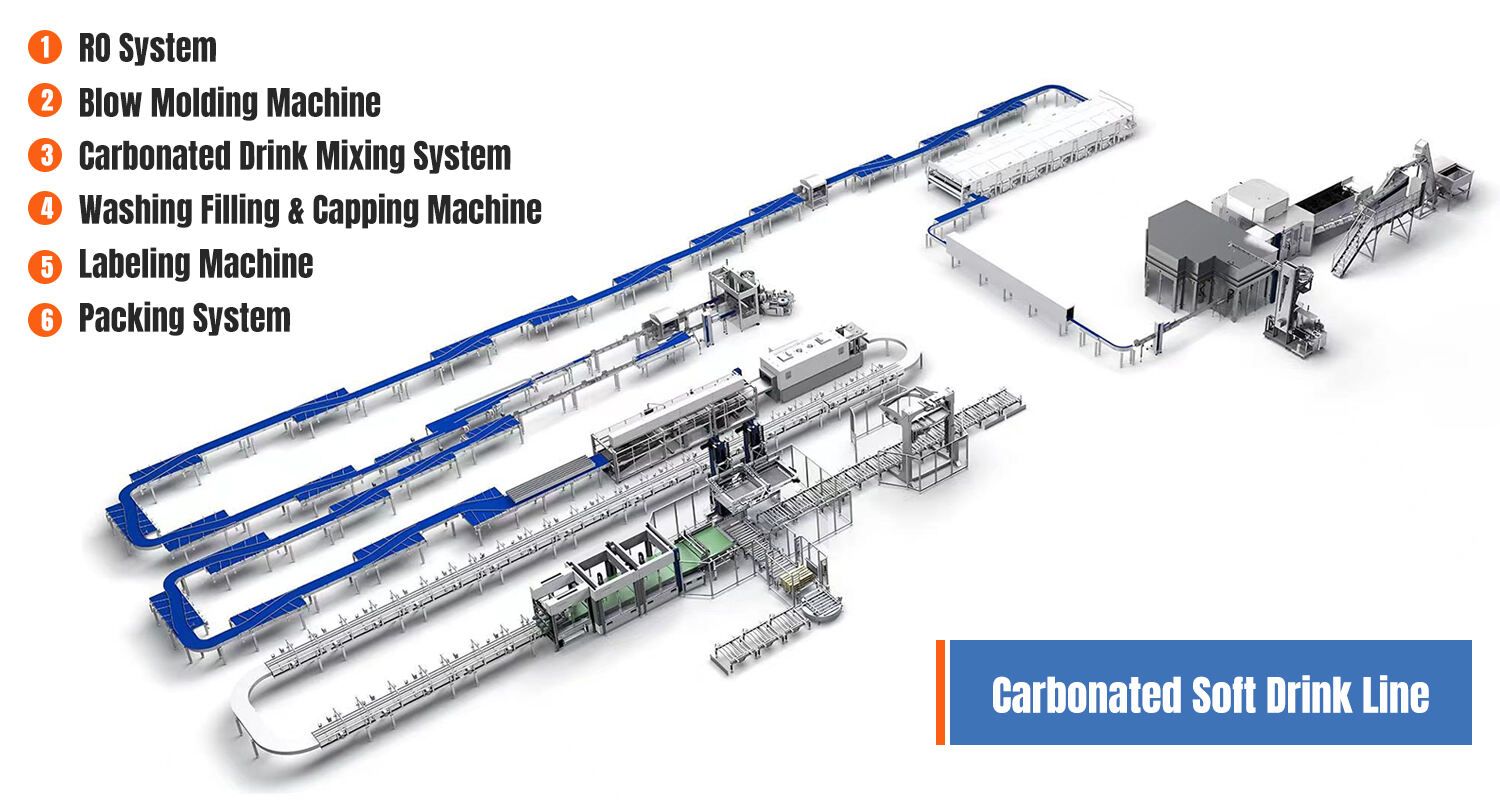

1. RO system

This RO system is very important in the whole water project, we prefer you supply water analysis report from your local inspection department. This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr. This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised. We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

2. Automatic blow molding machine for PET bottle:

Full automatic blowing machine from 2 cavity, 4 cavity, 6 cavity, 8 cavity, 9 cavity, etc from 2500BPH to 12000BPH for 500ml bottle

3. Automatic PVC sleeve shrink labeling machine:

Capacity: 100-350bottles/min can be chosen Label material: PVC PET OPS, etc

Bottle material: PET PE PP Glass Bottle Diameter: 28 ~ 120mm

Bottle Height: 15~320mm Bottle shape: round, square, ellipse, rectangular

Label length: 30~250mm max Label thickness: 0.03~0.13mm

4. High speed automatic PE film shrink packing machine:

Film material: PE Shrink membrane thickness: 70~100um

Capacity: 20-25packages/ min can be chosen Conveyor belt max width: 600mm

Height : 1000~1100mm

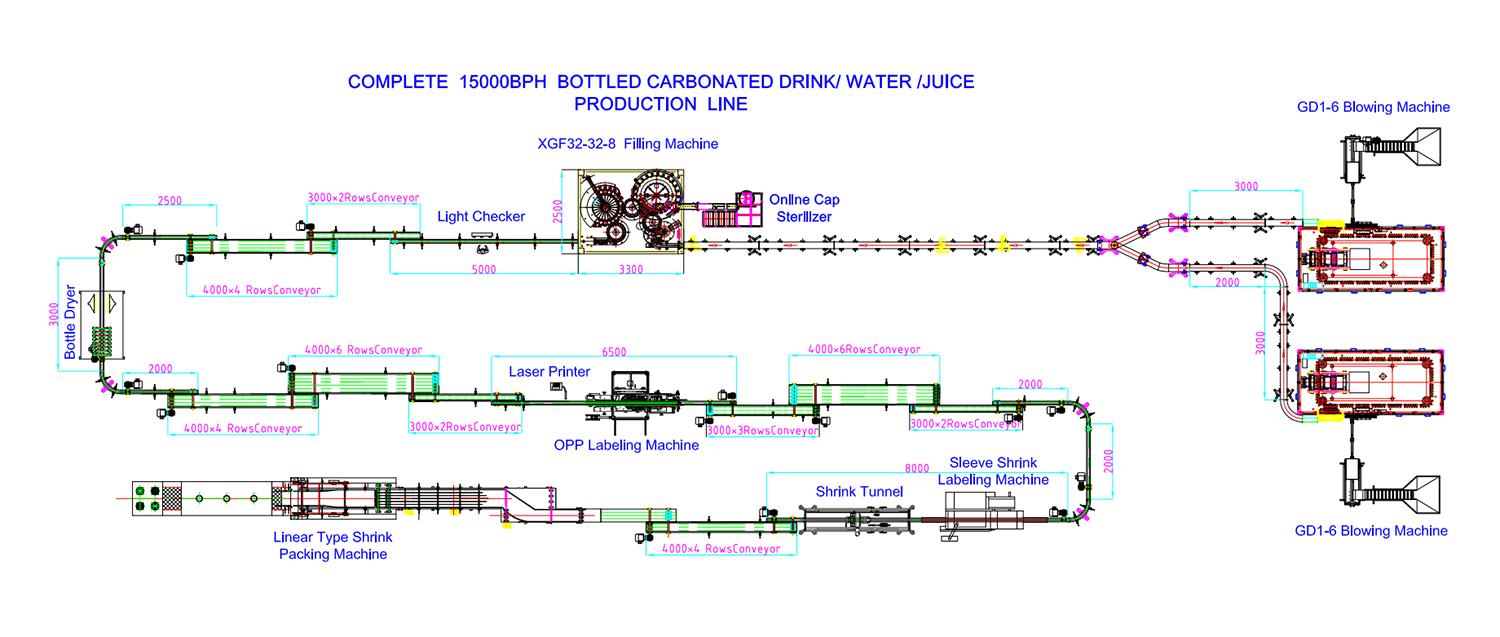

Turkey Project - Carbonated Drink/Water/Juice Production Line

Small Bottle Water Washing FIlling Capping Machine

Bottle volume: 200ml-2250ml Capacity: 12000BPH 500ml,5000BPH 1500ml

Juice Washing Filling Capping Machine

Juice Washing Filling Capping

Machine

Can Filling Sealing Machine

Application: Beer, Carbonated Drink, Sparkling Water, etc

High Speed PE Film Shrink Packing Machine

Packing speed: 22-28bags/min

Automatic Sleeve Shrink Labeling Machine

1. Single head or double heads available 2. Output: 150-350bottles/min

Automatic PE Film Shrink Packing Machine

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line, can filling and sealing line, complete blowing labeling and packaging system

For more information, please feel free to contact us to send inquiries

GRANDEE MACHINE

Starting the entire Automatic Round Bottle Aseptic Juice Washing Filling and Sealing Machine, delivered by this operational system is trusted GRANDEE MACHINE. This product is revolutionary is top-of-the-line been designed to provide the solution is most appropriate for the juice production needs.

Intended to the item quality requirements being greatest, this revolutionary product offers a simple yet effective and solution is dependable clean, fill, and seal your juice services and products. Utilizing level is advanced and materials are frequently your this top-grade that is particular manufacturing is actually safe, efficient, and hygienic.

Obtaining the charged ability to instantly neat and sterilize your bottles before filling them, this machine prevents contamination and signifies that the juice items are safe as well as top quality. Also, this product's automatic system is filling dispenses the juice to the containers, ensuring determination in the fill level and decreasing the threat of spills and waste.

A task is operate that easy can be managed insurance firms a person is easy touch-screen. This particular aspect is specific it really ideal for both tiny and juice is facilities being large-scale.

Carries a variety is wide of parameters that let you optimize your manufacturing procedure. This is made up of the capability to adjust the fee this is certainly bottle is filling, and quantity is filling. So you'll adjust the gear to raised suit the specific needs associated with juice manufacturing process.

Created to be multipurpose. It really is suited to a combination is wide of size and shapes, which makes it ideal for various juice products and services. This machine are capable of the whole thing from little glass containers to containers are big artificial.

The round that is entire is automated Bottle Juice Washing Filling and Sealing Machine from GRANDEE MACHINE will really supply you with the most useful results, every time.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM