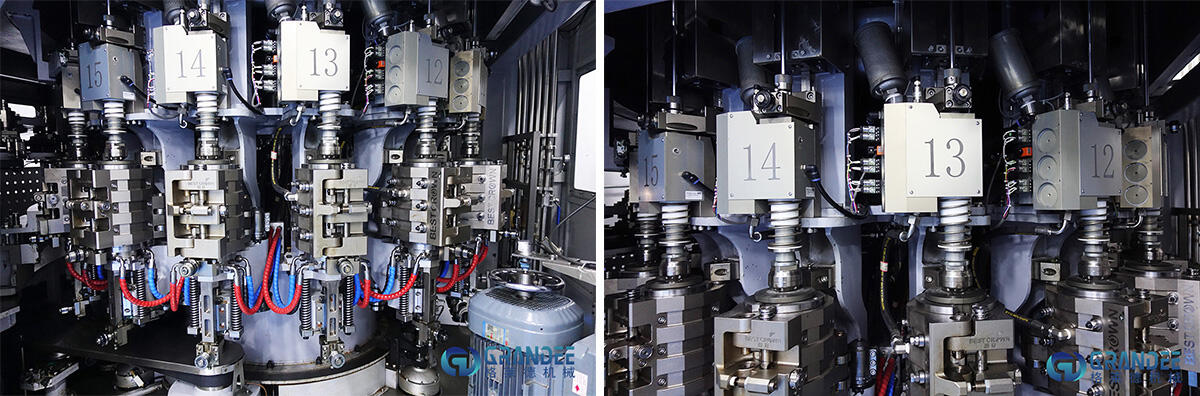

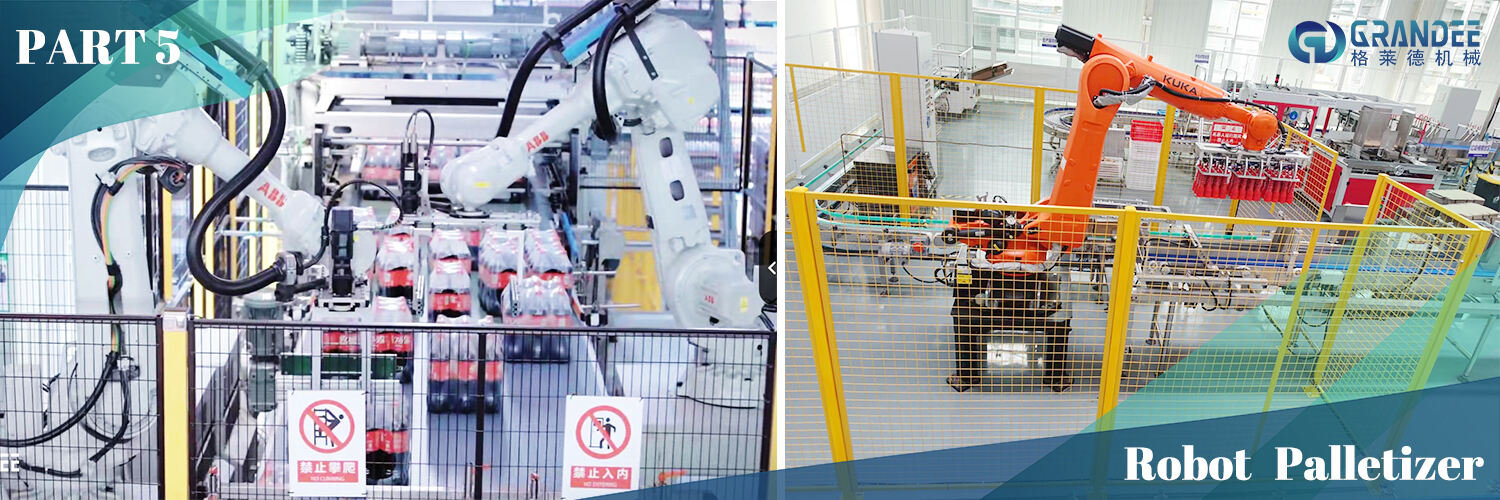

Each torque point and key point of the machine has torque protectors, photoelectric protection switches, stroke protection switches and other protective measures, so as to ensure the safe operation of the equipment, avoid the forced operation of the robot, thus extending the service life of the machine and the maintenance cost of accessories.

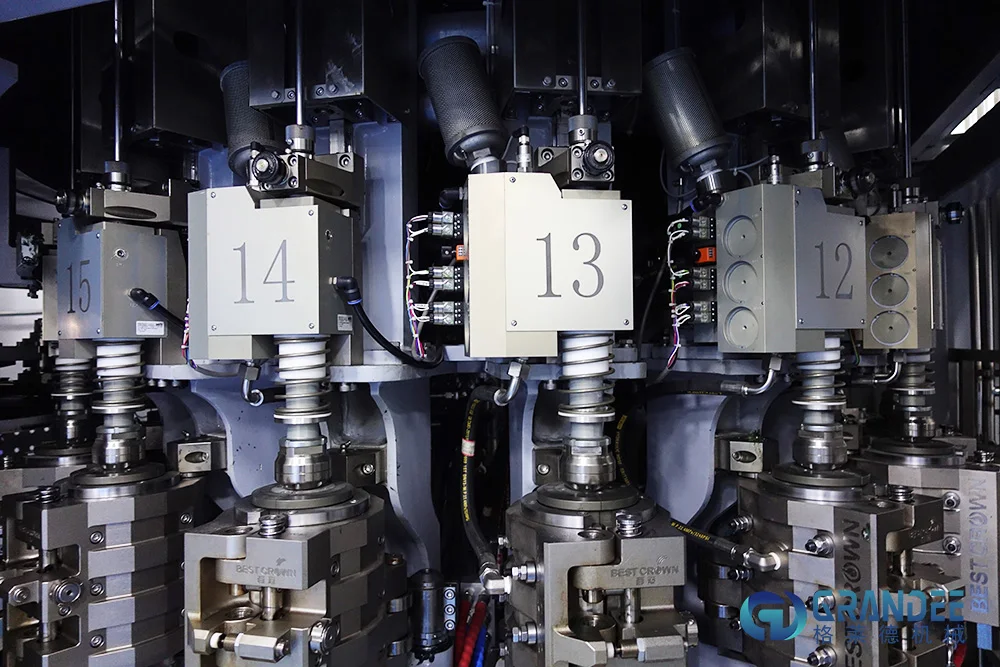

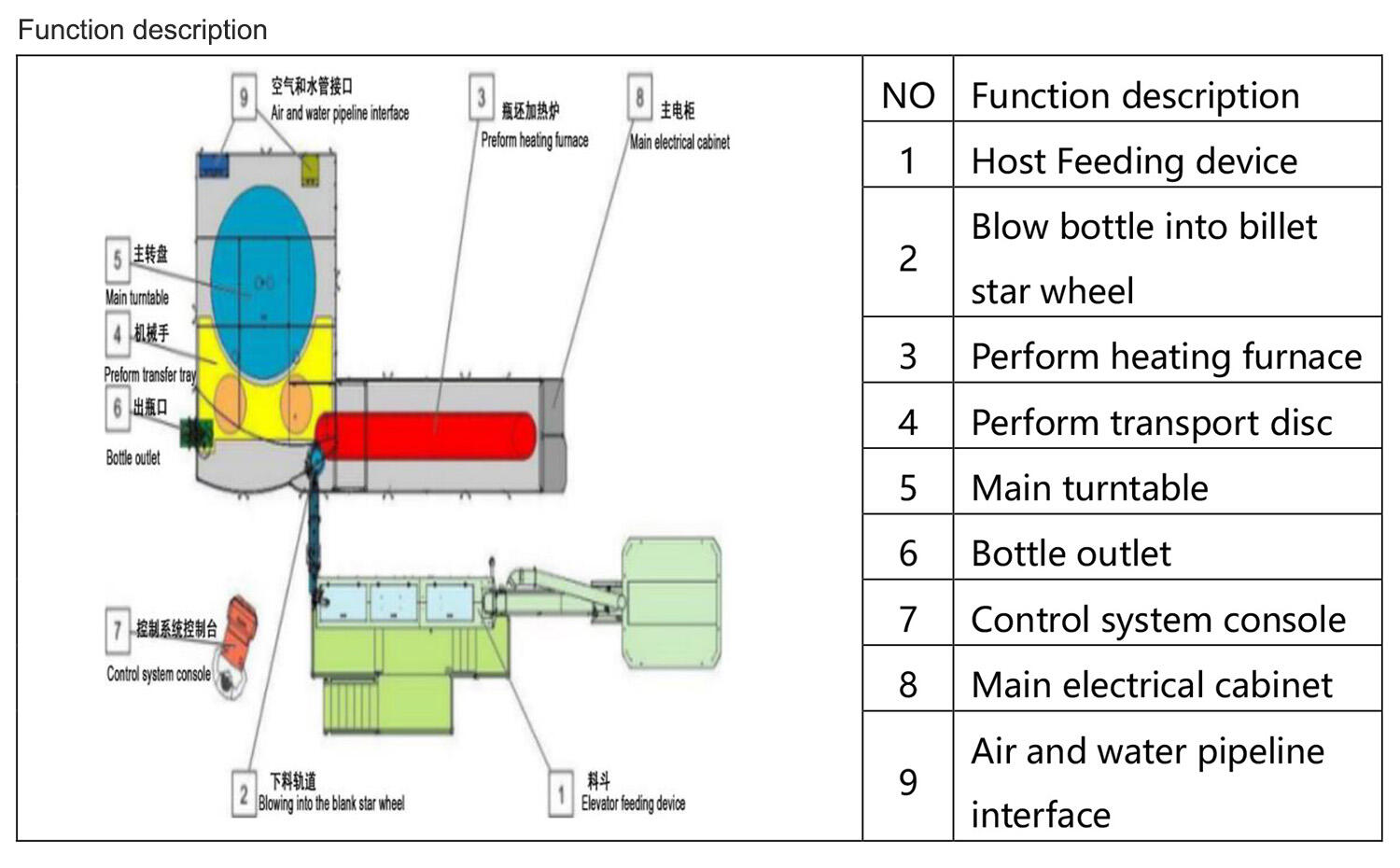

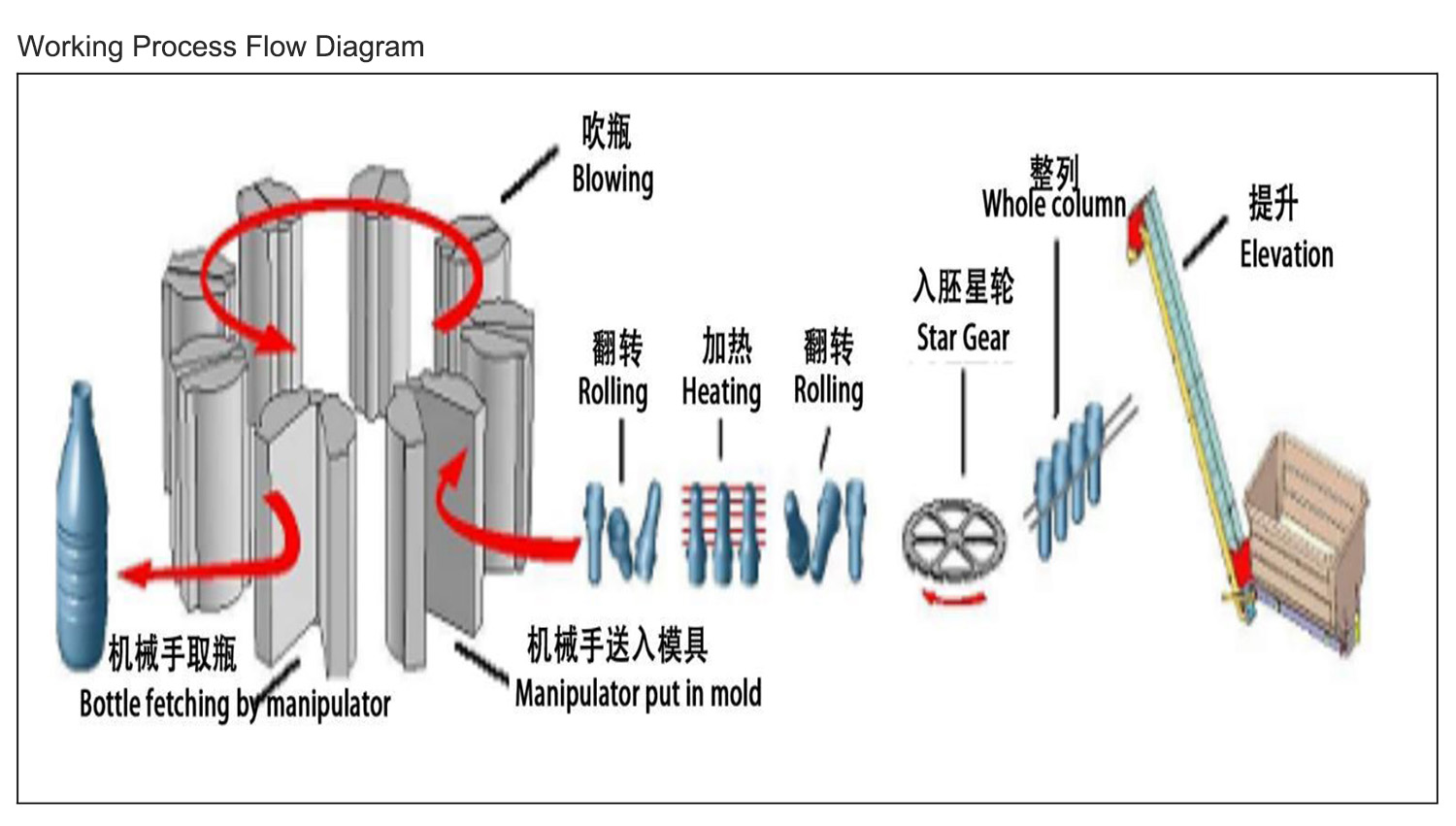

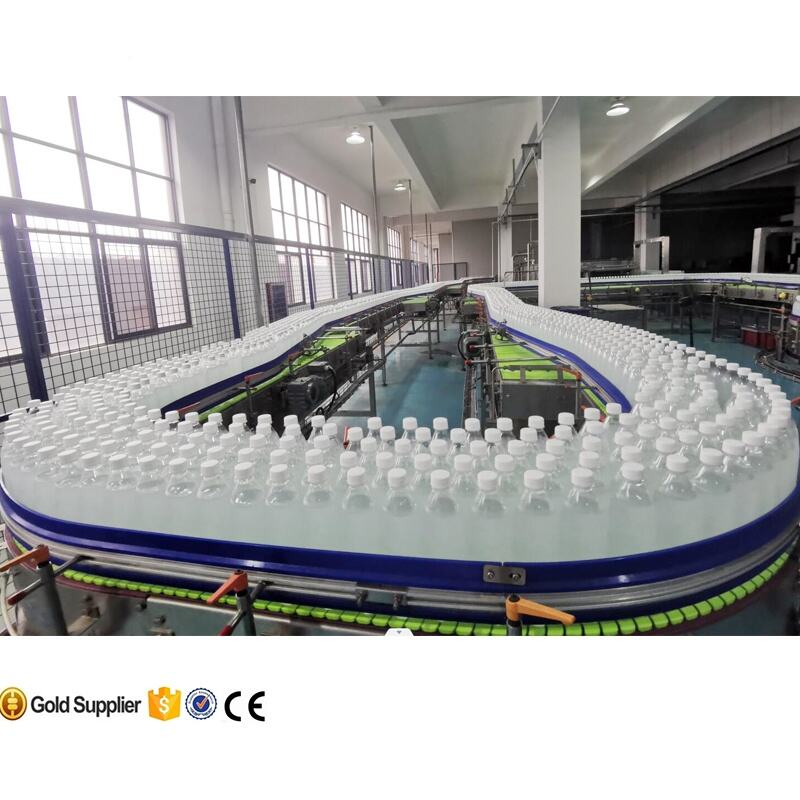

blowing machine is shown in the figure The automatic rotary blowing machine is a high-speed two-step blowing machine successfully developed by our company to absorb the most advanced bottle making technology in the world today. The machine is mainly composed of automatic feeding device (hopper, lifting mechanism, whole mechanism feeding track), heating furnace, main blowing machine, electrical control system and pneumatic control system.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM