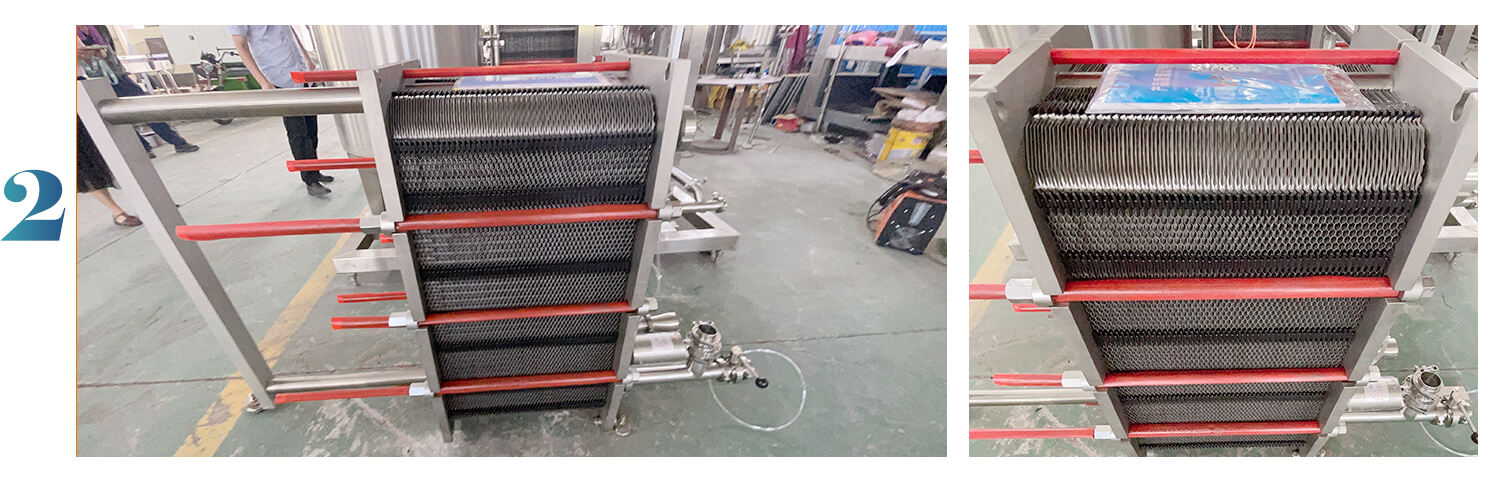

Plate heat excahnger

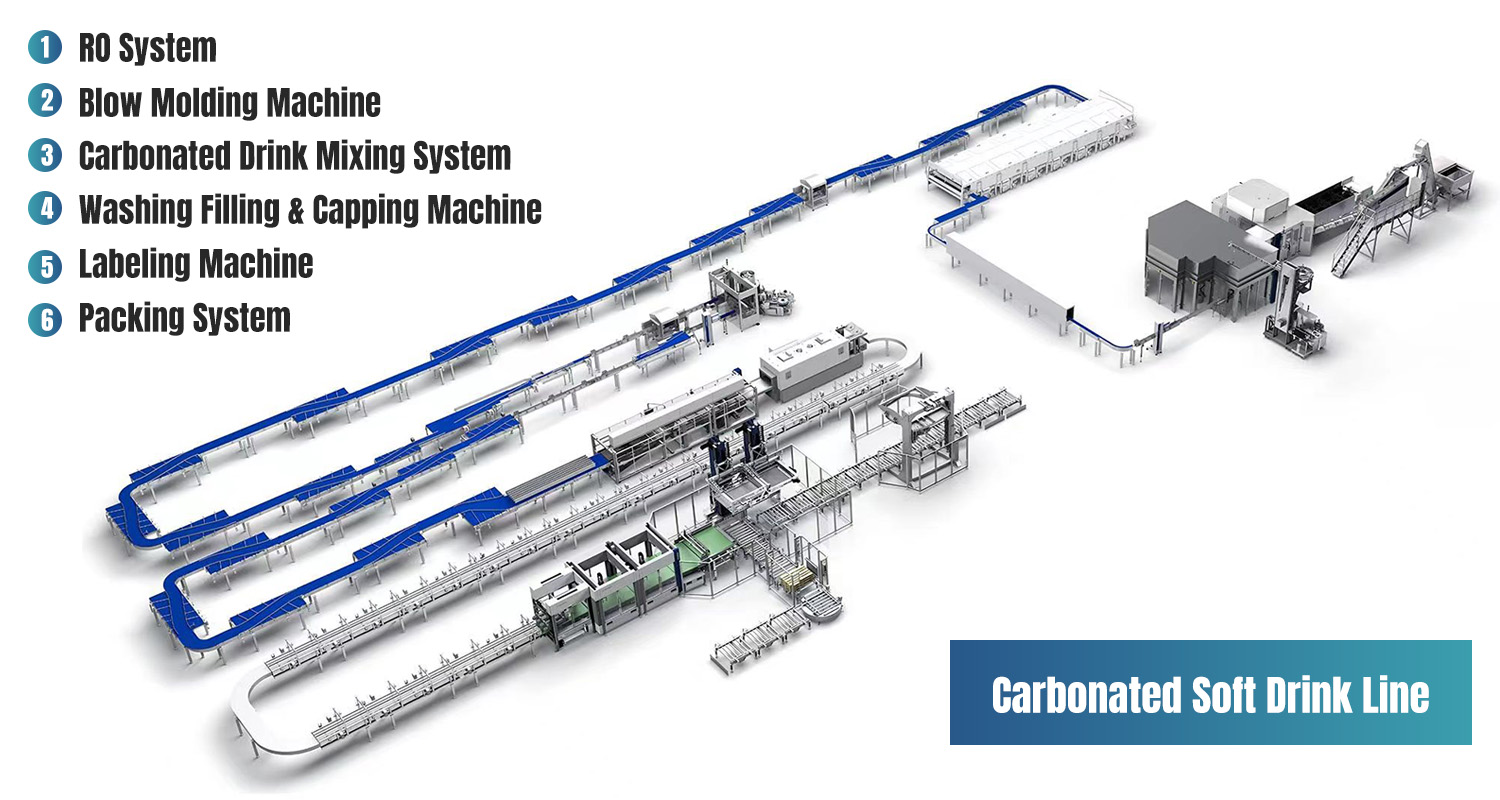

Plate heat exchanger is a kind of energy-saving equipment to realize the heat transfer between two or more kinds of fluids at different temperatures, which is to transfer the heat from the fluid with higher temperature to the fluid with lower temperature, so that the fluid temperature reaches the specified indicators of the process to meet the needs of the process conditions, and is also one of the main equipment to improve the energy utilization rate. It can be widely used in steel, power generation, non-ferrous metals, grease, chemical, petrochemical, shipbuilding, HVAC, refrigeration, pharmaceutical, dairy, beer, beverages, central heating and other fields.

The detachable plate heat exchanger is composed of metal heat exchange plate, front and rear baffle plate, sealant pad, guide rod, frame and so on. The adjacent plates and the sealant pad between them constitute a closed flow channel, and the hot and cold fluids flow through different flow channels and transfer heat through the plates under the guidance of the sealing pad to achieve the effect of heat exchange.

Area : 14㎡ Stainless steel 316L material plate, inlet and outlet φ51, A3 bracket, outer stainless steel, steam inlet and outlet φ51

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM