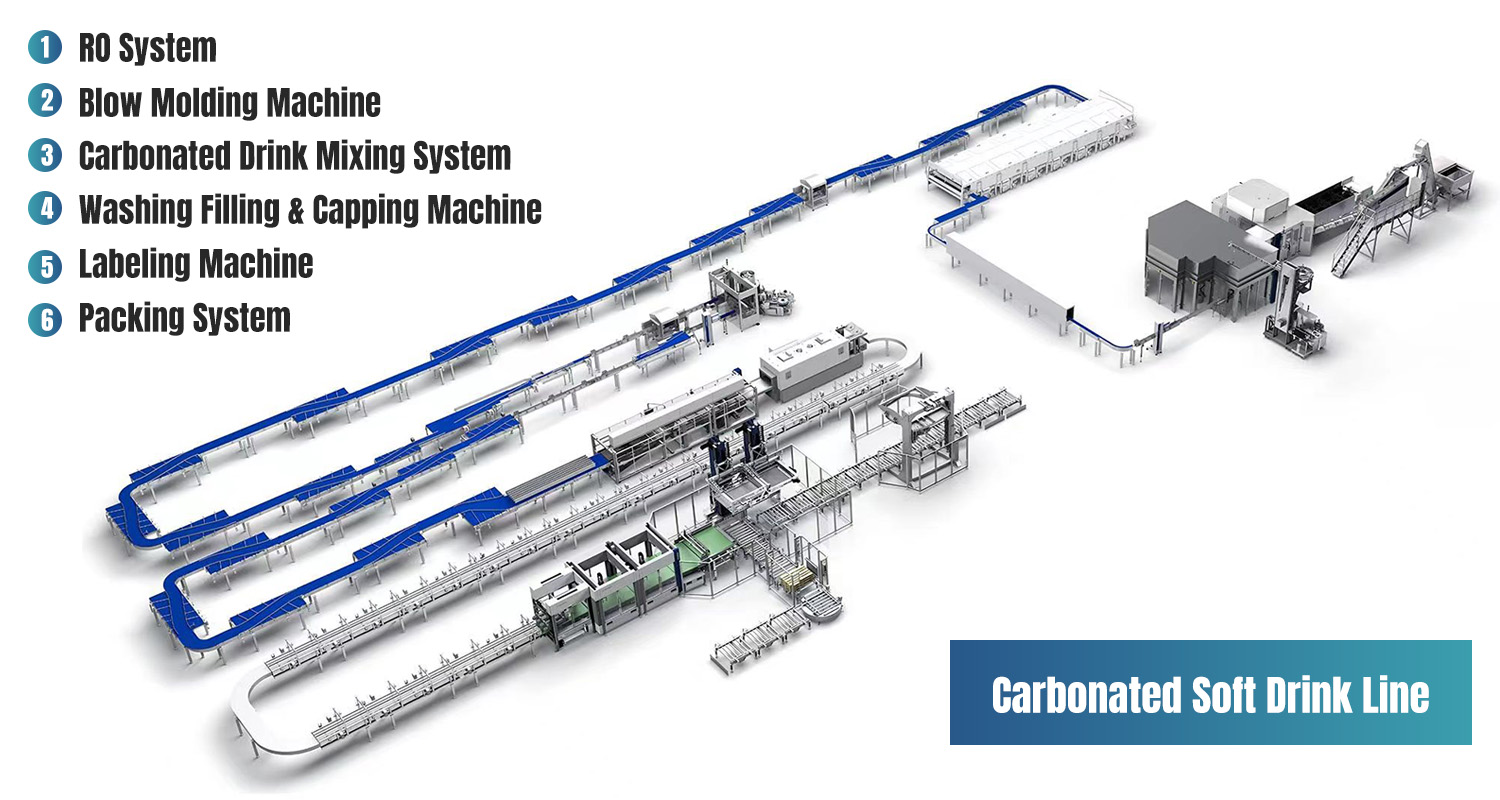

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

Carbonated Filling Machine DXGF50-50-12 Carbonated drink filling equipment adopts bottle neck holding transmission technology to realize fully automatic bottle rinsing, pulp filling, carbonated filling and cap screwing. It employs single cavity plunger type of fixing filling volume technique. It is equipped with CO2 accuracy pressure control, so that the liquid level is always stable. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation etc

Preform feed-in and unscrambler

It adopts the matured worldwide-standardized way of preform feed-in and unscrambling, in which preforms go through preform elevator and are transmitted to preform unscrambler. Inside the preform unscrambler, preforms are automatically sorted and delivered by two inclined revolving cylinders with same speed, and the remaining ones will be picked by star wheel and sent back to preform hopper. The whole process of preform unscrambling is fully automatic and has high efficiency without preform scratches.

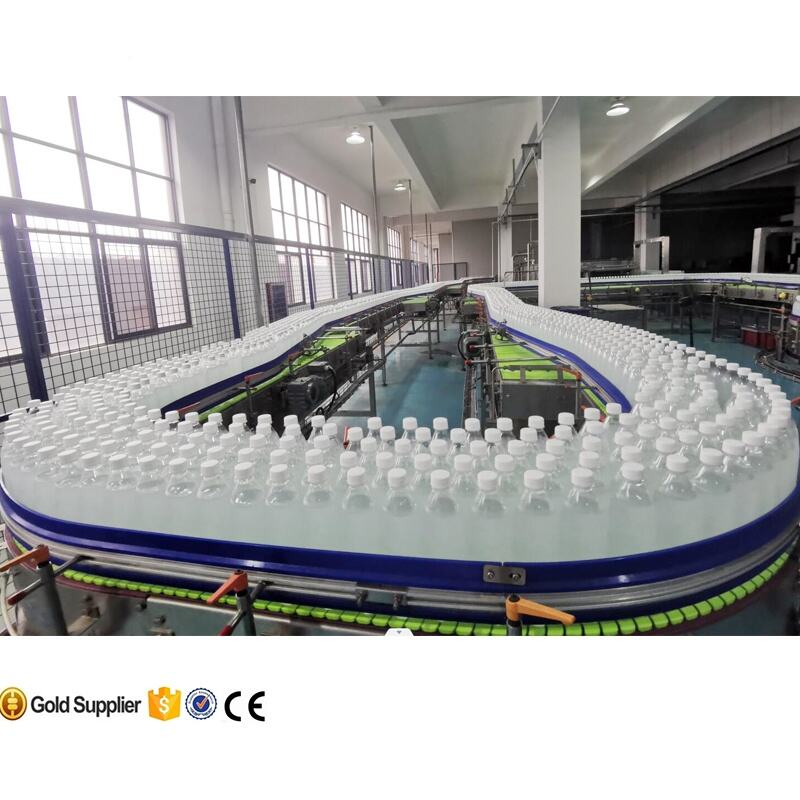

Washing part Into bottle way is air conveyor direct connection with bottle dial.

All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean. 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing. 304/316 stainless steel washing pump make the machine more durable.

Filling part

304/316 Stainless steel high precision filling nozzle Filling volume adjustable in fine rank, same liquid level after filling All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean 304/316 stainless steel filling pump Efficient spray nozzle rinse thoroughly and save water for flushing

Capping part Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping All 304/316 stainless steel construction No bottle no capping Automatic stop when lack of bottle Capping effect is stable and reliable, Defective rate ≤0.2%

|

Model

|

DXGF

14-12-5

|

DXGF

18-18-6

|

DXGF

24-24-8

|

DXGF

32-32-8

|

DXGF

40-40-12

|

DXGF

50-50-12

|

|

|

|

|

|

|

Capacity (500ml)

|

2000-3000

|

3000-5000

|

5000-7000

|

8000-9000

|

10000-12000

|

12000-14000

|

|

|

|

|

|

|

Suitable bottle shapes

|

PET circular

|

|

|

|

|

|

|

Bottle diameter

|

50-115mm

|

|

|

|

|

|

|

Bottle height

|

160-320mm

|

|

|

|

|

|

|

Filling type

|

Isobaric filling

|

|

|

|

|

|

|

Filling pressure

|

<0.4MPa

|

|

|

|

|

|

|

Rinsing water pressure

|

>0.06MPa <0.2MPa

|

|

|

|

|

|

|

Application

|

Carbonated soft drink bottling line

|

|

|

|

|

|

|

Total power

|

4.4kw

|

5.2kw

|

6.2kw

|

7.5kw

|

8.2kw

|

11kw

|

|

|

|

|

|

|

Overall dimensions

|

2.5*1.9m

|

2.8*1.9m

|

3.2*2.2m

|

3.4*2.5m

|

4.8*2.3m

|

5.5*3.3m

|

|

|

|

|

|

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

|

|

|

|

|

|

Weight

|

3000kg

|

4500kg

|

6000kg

|

8500kg

|

10000kg

|

11000kg

|

|

|

|

|

|

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

AIR CYLINDER

|

SMC

|

Japan

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

Title goes here

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes

Title goes here

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes

Title goes here

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes

Title goes here

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes

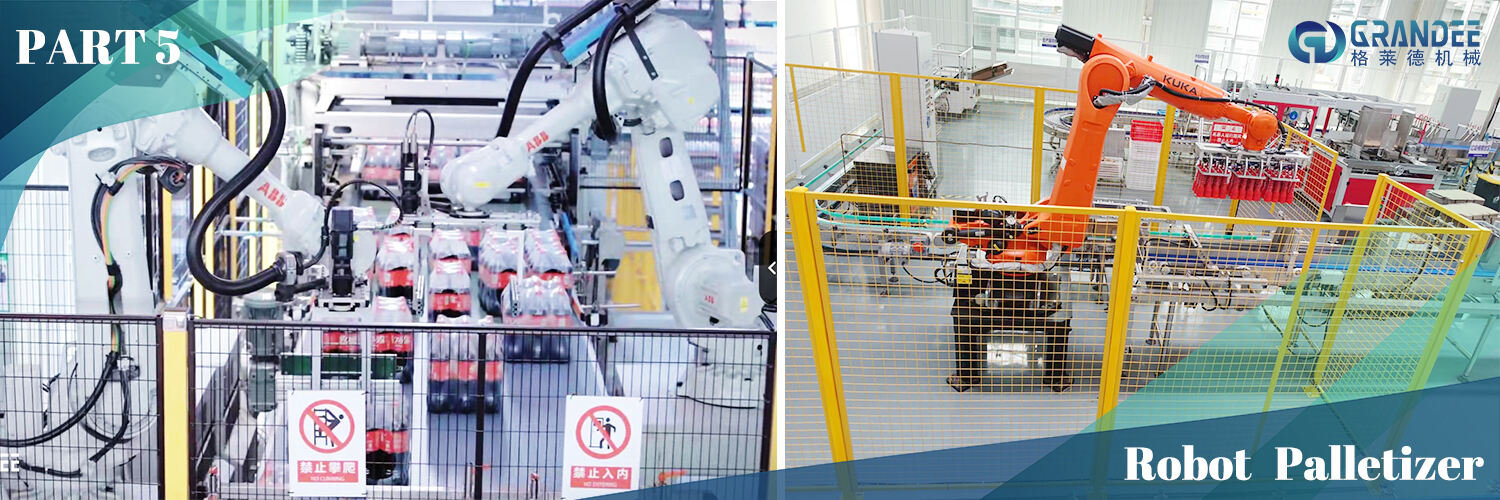

Robot Palletizer system has a compact body and a high throughput. It is suitable for packing bottled drinking water, juice, carbonated soft drinks etc. with production capacity up to 520layer/h. Suitable robot models can be selected according to the work pieces. Payload 110kg, 140kg, 185kg, 315kg, 500kg, 700kg

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line, can filling and sealing line, complete blowing labeling and packaging system

Q1: How to find suitable machine or complete beverage production line?

A1: Looking for beverage filling machine in www. Grandee Machine. en. alibaba. com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team, providing good and after-sales service term, professional salesman terms

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee, and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing

Grande Machine

Introducing the Automatic Plastic PET Bottle Carbonated Beverage Soda Sparkling Water Soft Drink Filling Machine. This innovative product is designed to fill plastic PET bottles with carbonated beverages such as soda, sparkling water, and soft drinks automatically.

The Grande Machine Filling Machine fills bottles, cans at high speed while giving a fully manual no fill solution to your beverage business. It can fill at a rate of up to 3000bph (based on the size bottle you are filling making it ideal for small and medium scale beverage production due to its modern technology.

It is a product of high-quality which makes it long-lasting and very efficient. It includes an automatic GRANDEE MACHINE system that fills the bottles to a high level of equivalent carbonation or exceeds those from established bottling lines. It features a touch screen control panel for simple filling parameter set up by the user. This can only lead to even further convenience, saving time and enhancing productivity for all users.

Additionally, the traditional this machine with a tough frame that keeps going and doing its job day after day, fits perfectly well. The machine is corrosion resistant and therefore easy maintain since it has an all-Stainless-steel construction. This machine is user friendly and easy to operate, even for equipment operators with Bit experience of using this type of machinery.

Compact and can save room, so you do not have to rearrange your production line. It can be integrated into your existing manufacturing line and it has conveyor system to feed the bottles to Filling station, move them further for capping operation, followed by Labeling at other stage.

Created in accordance with all global quality standards. Reliable and safe for your beverage production needs. Entrepreneurs who wish to streamline their production process and improve efficiency should consider the cost-effective machine.

Invest in the Grande Machine and elevate your beverage production line to the next levels.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM