GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

Products Description number

|

Name |

Brand /Material |

Origin |

1 |

Screw/barrel |

Ouwei/Fuyi/Tongda(38CrMoAL) |

China |

2 |

Three templates and injection head, second plate |

QT500 |

China |

3 |

Servo Motor |

Synmot |

China |

5 |

Hydraulic Motor |

Delson |

Italy |

6 |

Stroke Switch |

Honeywell/OMRON/Panasonic |

USA/Japn |

7 |

Air Switch |

SCHNEIDER//LG |

France/ Korea |

8 |

AC Contactor |

SCHNEIDER |

France |

9 |

Thermal relay |

SCHNEIDER |

France |

10 |

Controller |

TECHMATION |

Taiwan, China |

11 |

Electronic Ruler |

Jiesheng |

USA |

12 |

Pump |

Oufeite |

China |

13 |

Solenoid valve |

YUKEN |

Japan |

14 |

Oil seal/dust seal |

VALQUA/HALLITE |

Japan/UK |

15 |

KDAS wearing ring |

HALLITE |

UK |

16 |

Servo controller |

Mengde |

China |

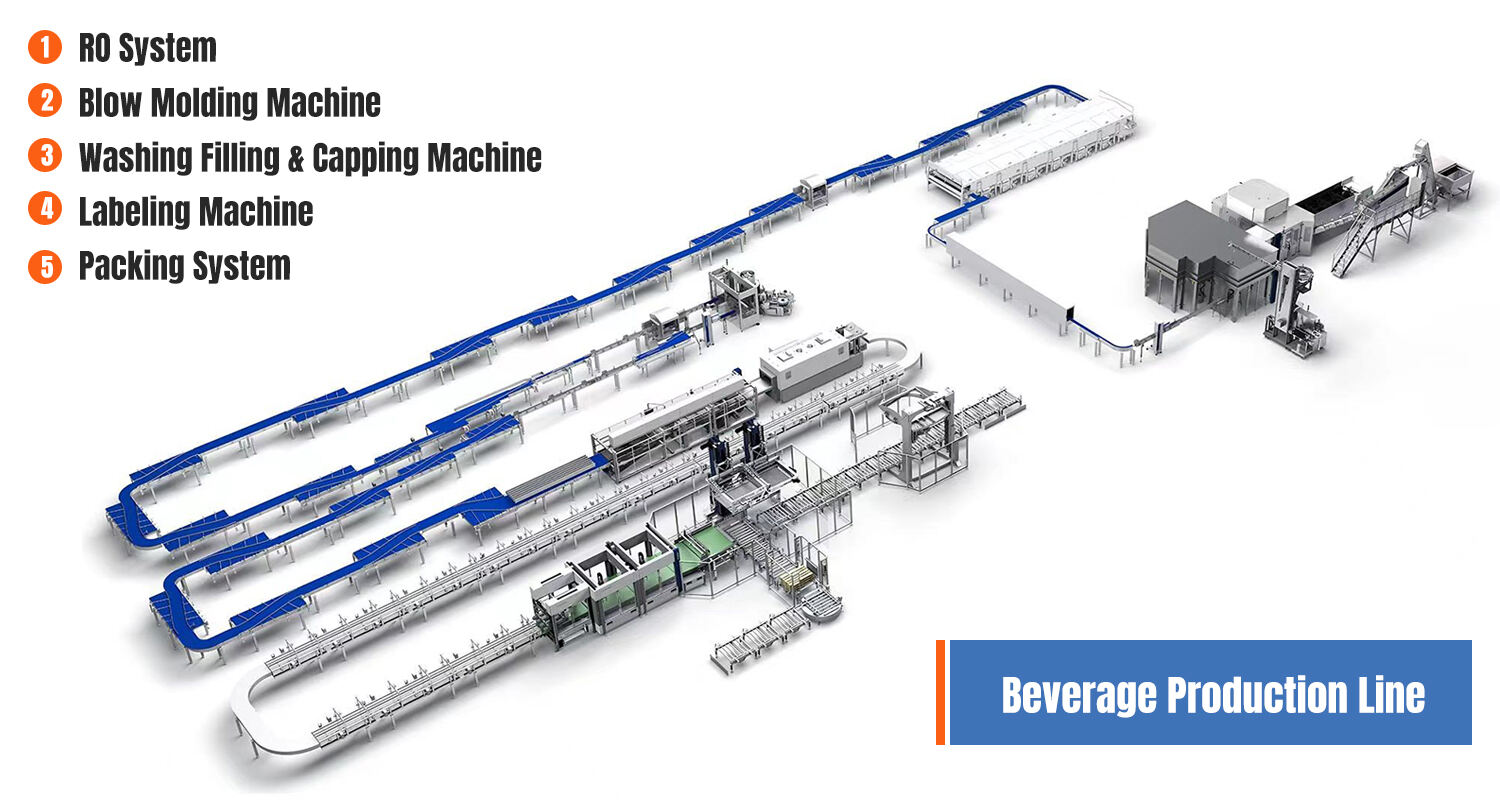

1. RO system

This RO system is very important in the whole water project, we prefer you supply water analysis report from your local inspection department. This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr.

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised. We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

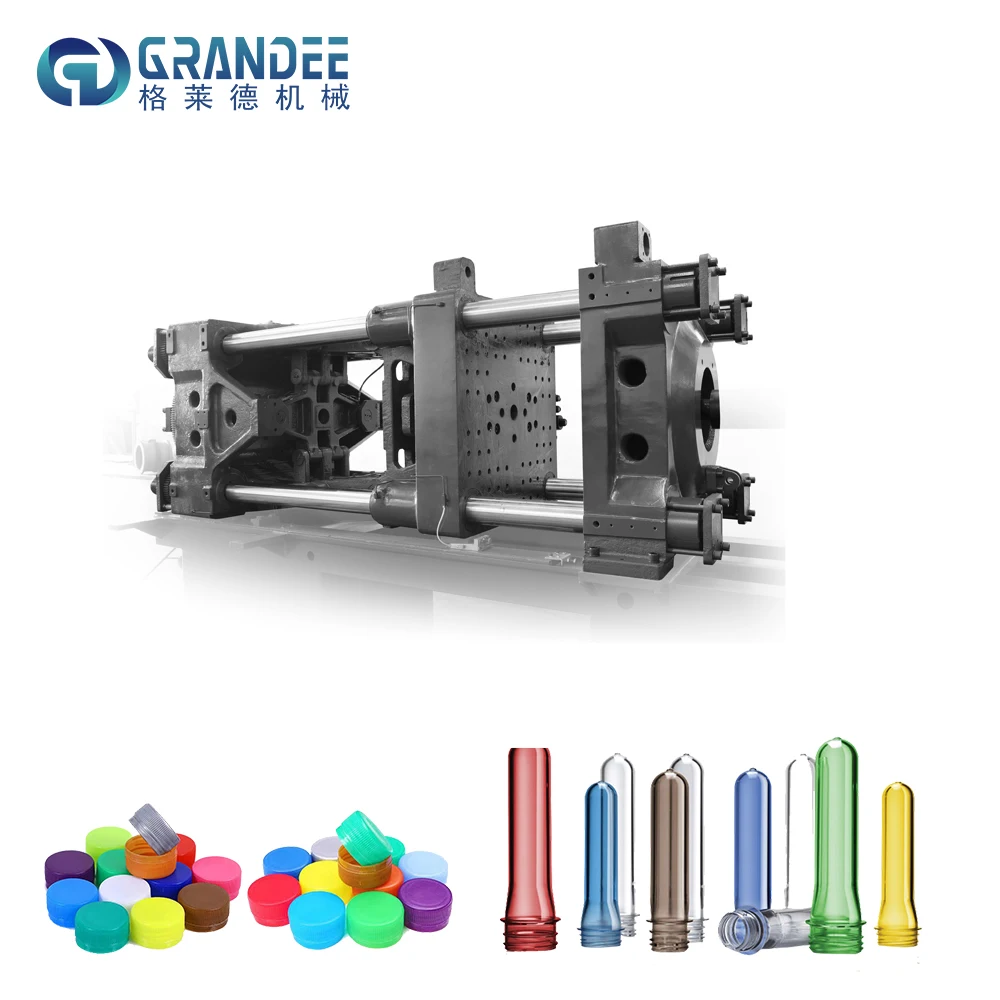

2. Automatic blow molding machine for PET bottle:

Full automatic blowing machine from 2 cavity, 4 cavity, 6 cavity, 8 cavity, 9 cavity, etc from 2500BPH to 12000BPH for 500ml bottle.

3. Automatic OPP hot glue labeling machine:

Capacity: 100-350bottles/min can be chosen Label material: PVC PET OPS, etc

Bottle material: PET PE PP Glass Bottle Diameter: 28 ~ 120mm

Bottle Height: 15~320mm Bottle shape: round, square, ellipse, rectangular Label length: 30~250mm(max) Label thickness: 0.03~0.13mm

4. High speed automatic PE film shrink packing machine:

Film material: PE Shrink membrane thickness: 70~100um

Capacity: 20-25packages/ min can be chosen Conveyor belt max width: 600mm

Height: 1000~1100mm

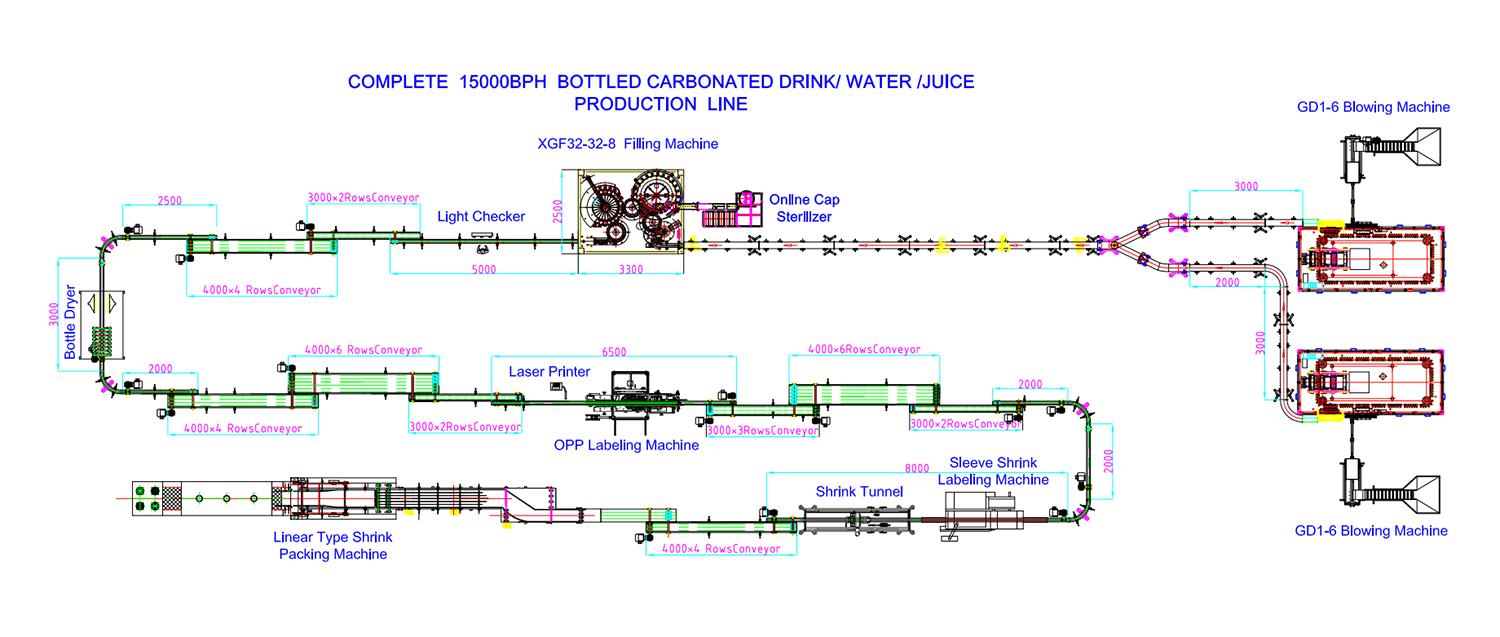

Turkey Project - Carbonated Drink/Water/Juice Production Line

Small Bottle Water Washing FIlling Capping Machine

Bottle volume: 200ml-2250ml

Capacity: 12000BPH 500ml,5000BPH 1500ml

Juice Washing Filling Capping Machine

Juice Washing Filling Capping

Machine

Can Filling Sealing Machine

Application: Beer, Carbonated Drink, Sparkling Water, etc

High Speed PE Film Shrink Packing Machine

Packing speed: 22-28bags/min

Automatic Sleeve Shrink Labeling Machine

1. single head or double heads available

2. Output: 150-350bottles/min

Automatic PE Film Shrink Packing Machine

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line, can filling and sealing line, complete blowing labeling and packaging system

Q1: How to find suitable machine or complete beverage production line?

A1: Looking for beverage filling machine in www. grandee machine. en. alibaba. com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team, providing good and after-sales service term, professional salesman terms

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee, and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing

GRANDEE MACHINE

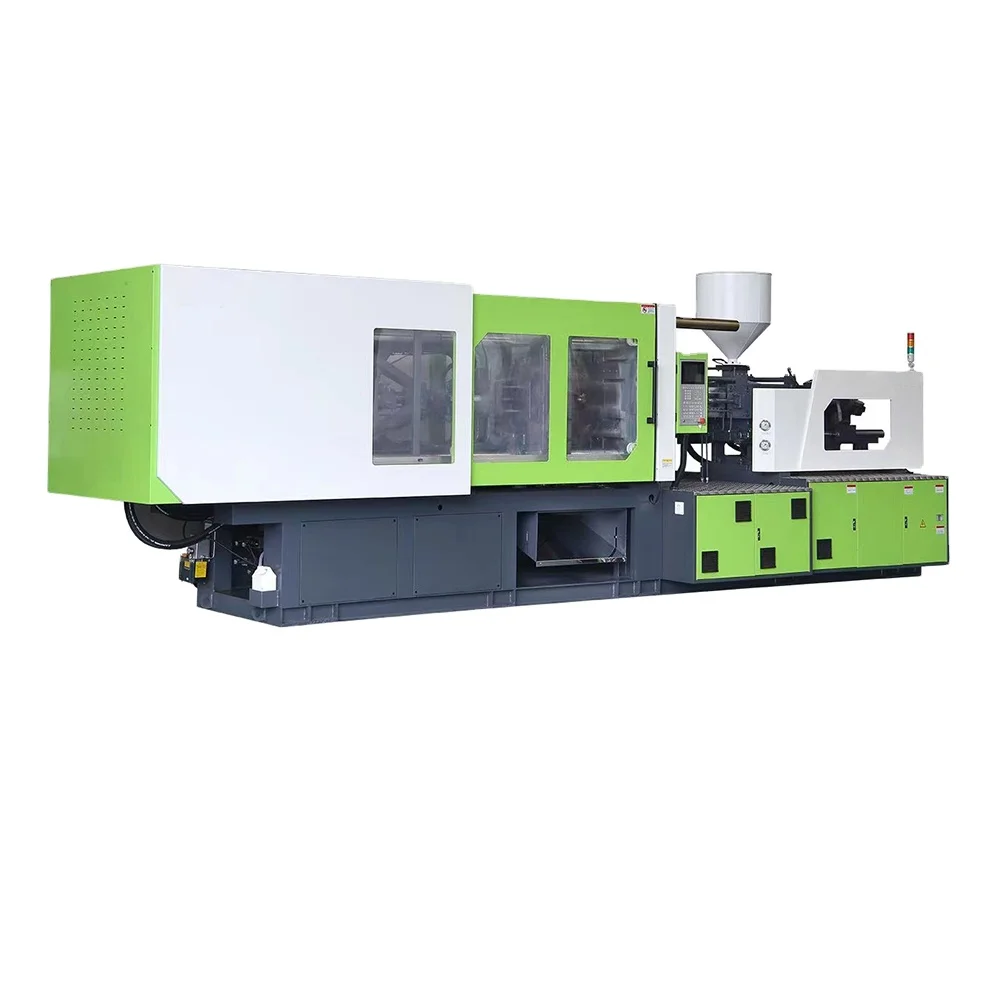

If you're in need of a machine that can make plastic chairs with ease, look no further than the Grande Machine Automatic Plastic Chair Making Machine. with a 170-ton Plastic Injection Molding Machine, this product is capable of producing high-quality chairs quickly and efficiently.

One regarding the standout top features GRANDEE MACHINE of this machine is its automatic operation. You won't require to concern yourself with manually controlling the injection process, since the machine are designed for everything on its very own. This will make the production procedure faster and more reliable, as there's less space for human error.

Can be designed with durability in mind. Its sturdy construction guarantees so you won't need to worry about it breaking down or requiring regular repairs it can withstand heavy usage over time. This means less downtime and greater productivity into the run is long.

One more thing is great this device is its user-friendly user interface. Even though you're not familiar with injection molding, you'll find the settings easy to understand and navigate. This makes it an option is very good businesses just getting started with synthetic chair production.

Of course, the many things is important it comes to any manufacturing machine is the quality regarding the end product. Using the Grande device Automatic Plastic Chair Making Machine, you may be confident that the chairs it produces are of the standard is highest. The machine is capable of creating seats with consistent quality, free from defects or irregularities.

The Grande Machine Automatic Plastic Chair Making Machine is a top-of-the-line product that can help take your business to the next level. with its automatic operation, durability, user-friendly interface, and high-quality output, it's the perfect investment for businesses looking to boost their production capabilities.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM