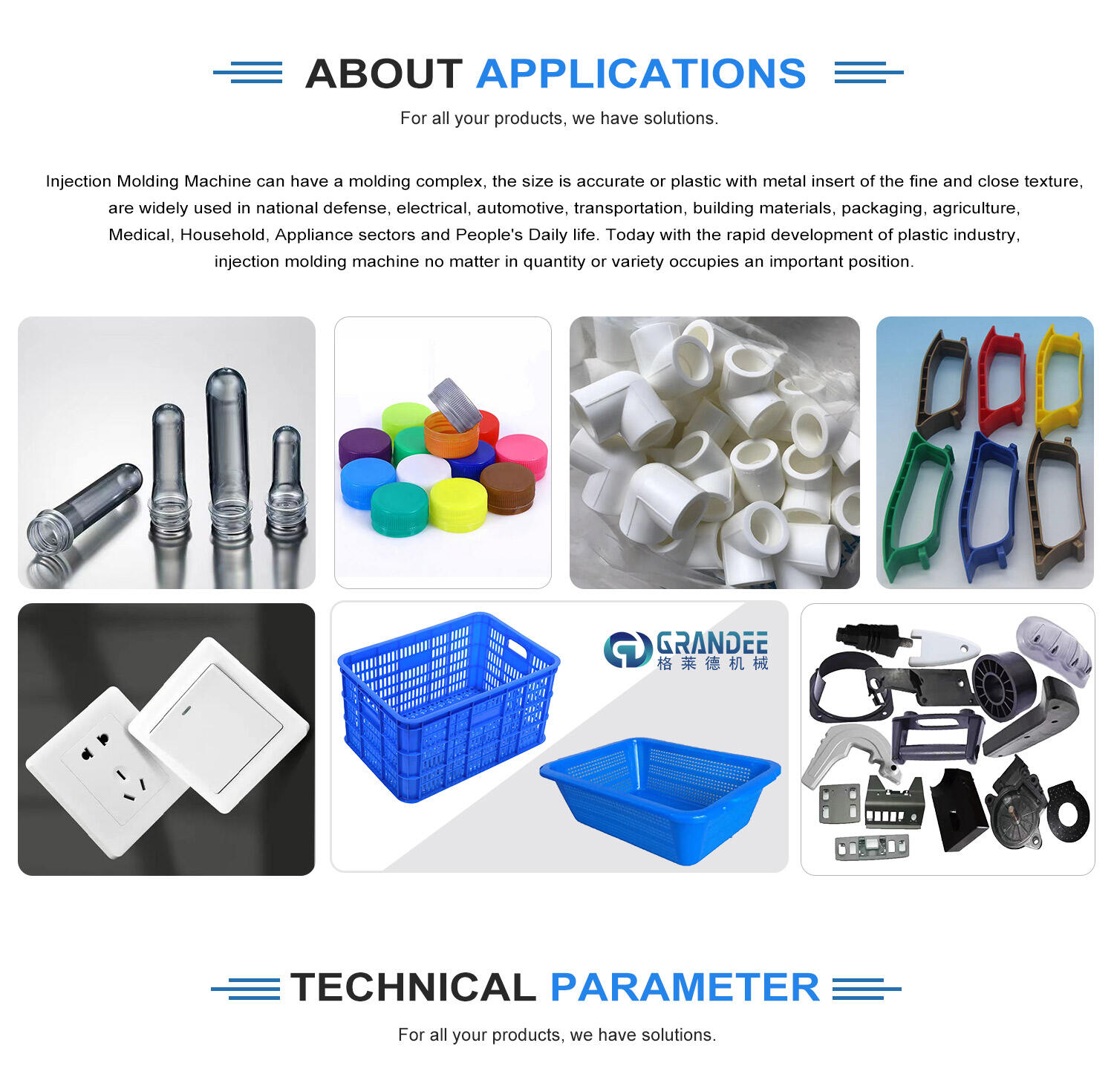

Introducing, the Automatic Horizontal Injection Plastic Molding Machine, proudly brought to you by GRANDEE MACHINE, designed to make plastic bucket production easier and more efficient than ever before.

This machine features a horizontal injection system and a high-performance servo motor, ensuring precise and stable injection molding. It also has an automatic mold adjustment function, which can quickly and accurately adjust the mold according to the size of the bucket being produced.

Operating the Automatic Horizontal Injection Plastic Molding Machine is simple and easy to understand, with a user-friendly interface and state-of-the-art controls. The machine is also equipped with a multi-language operating system, allowing for smooth operation in many different languages.

One of the outstanding features of this machine is its energy-saving capabilities. It incorporates advanced energy-saving technology, including variable pumps and a proper cooling system, which reduces energy consumption and slashes production costs resulting in increased profit margins.

The Automatic Horizontal Injection Plastic Molding Machine is built to last, made of high-quality materials and advanced technology, ensuring that it is durable and safe to use. It also features an automatic lubrication system, which ensures that the machine is always lubricated, improves efficiency and prolongs its lifespan.

With a maximum capacity of up to 30 liters, this machine can produce plastic buckets ranging from 1 liter to 30 liters in size, suitable for a vast array of industries, including food, chemical, and agricultural

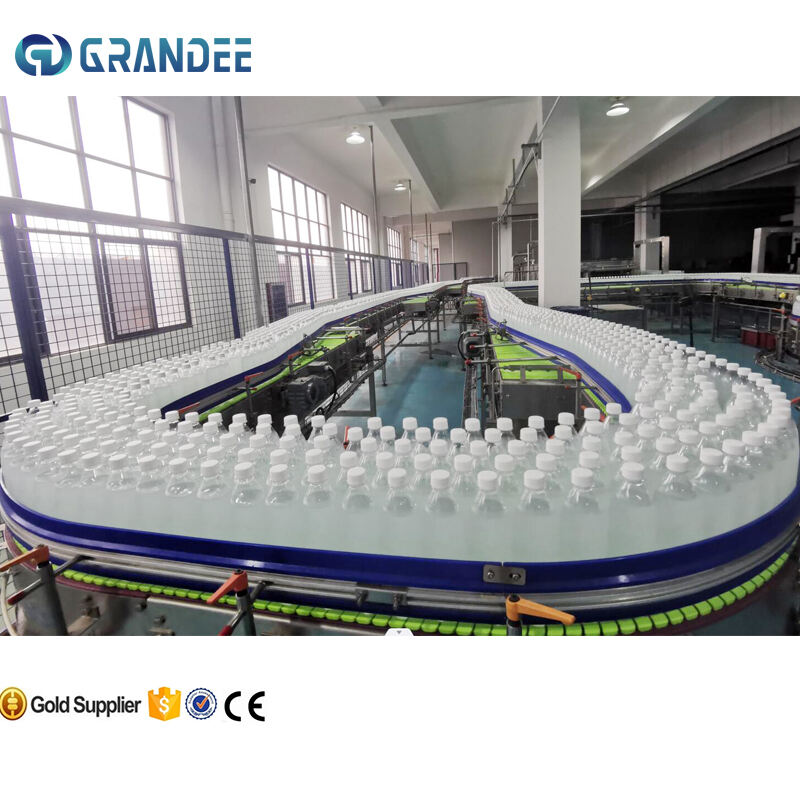

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

Machine features:

Injection molding machine usually consists of the injection system, clamping system, hydraulic drive system, electrical control system, lubrication system, heating and cooling systems, security monitoring systems and other components. Working principle of injection molding machine is similar with an injection syringe, it is by means of a screw (or plunger) of thrust, make good plasticized molten state (ie, viscous state) good plastic injected into the closed mold cavity to obtain shaped articles after curing. Injection molding is a cyclic process, with each cycle

Including:quantifying feeder-molten plastics pressure injection-filling mold cooling-open mold and pick up products. Take out the plastic parts and then go into next cycle operation

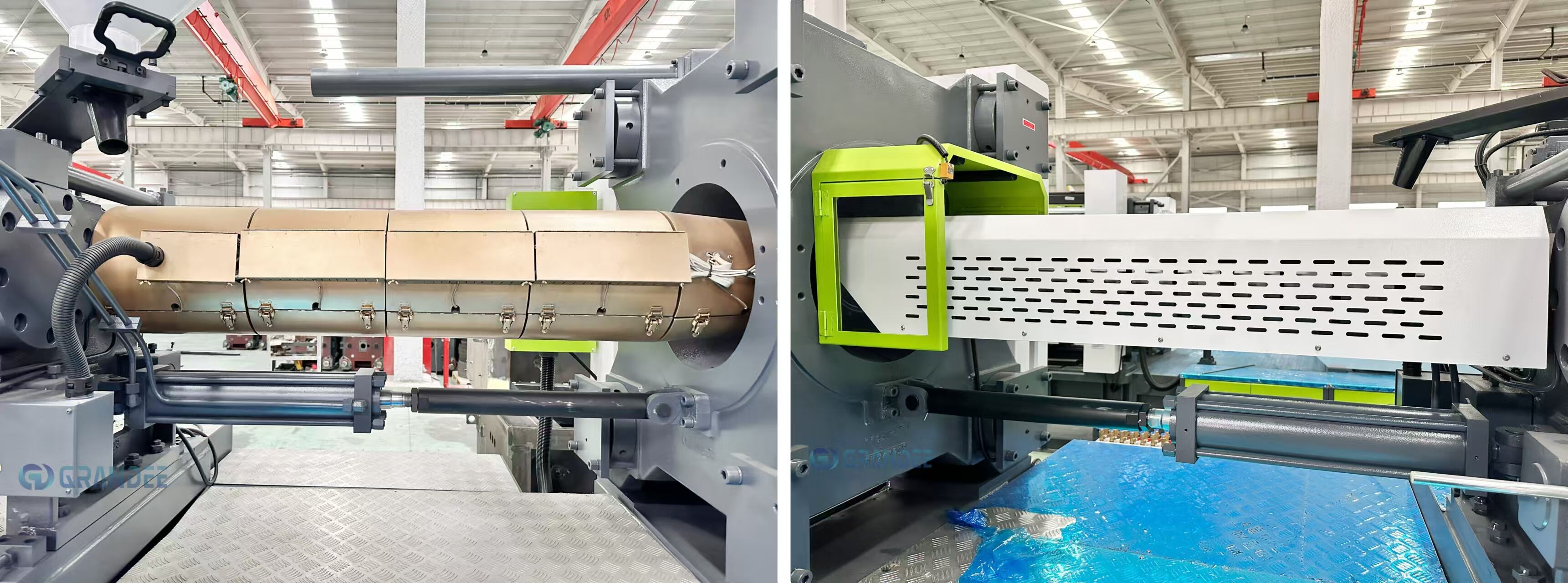

Nanometer infrared heating ring:

Nano infrared heating ring has better insulation effect, small heat loss, faster heating, faster feeding. On this basis, the hydraulic nozzle is added to prevent the material from flowing out

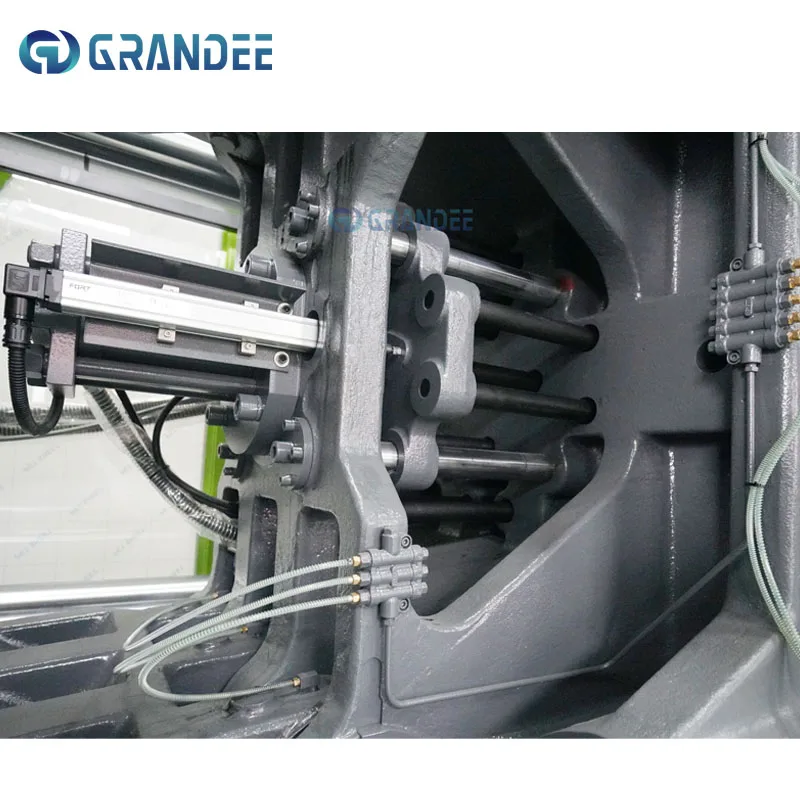

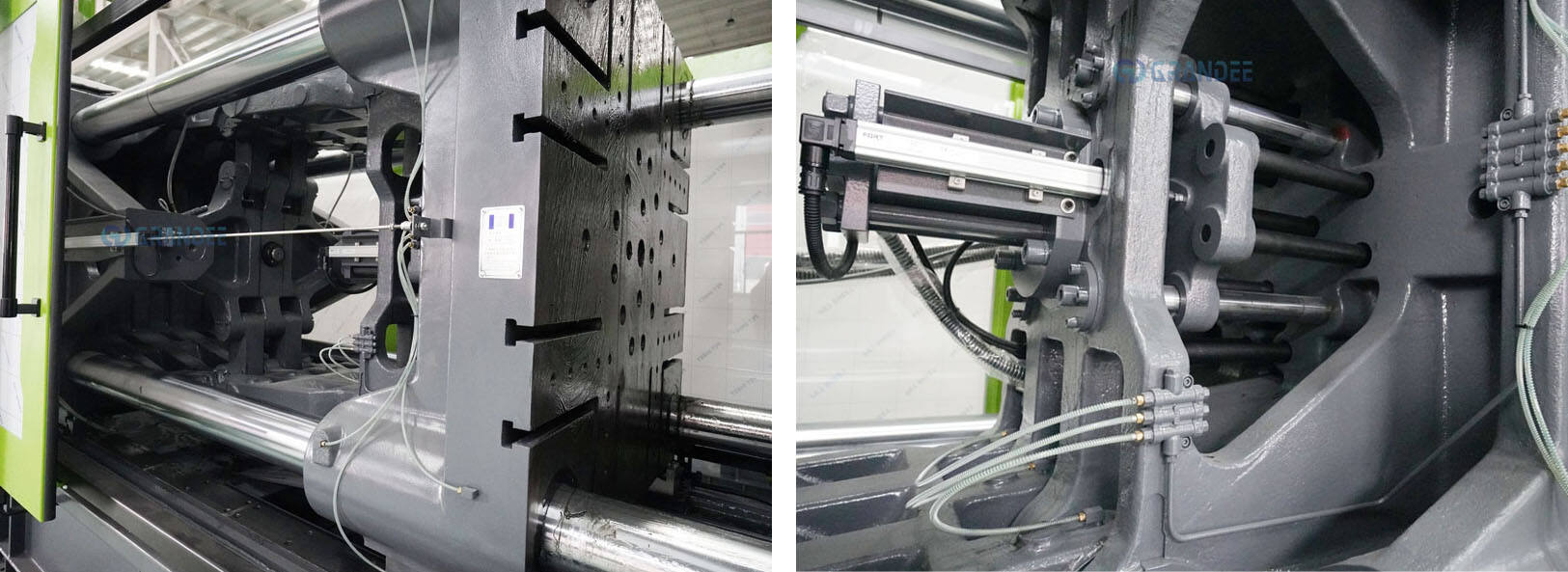

Clamping Unit:

5-point twin toggle clamping system by modular optimization software designing. Strong clamping with rapid and stable, to meet the strict clamping condition. Mould height adjustment by hydraulic driven gear system with rapid and stable. Automatic mould height adjustment as per the setting clamping force, optional

Injection Unit:

Balanced double injection cylinder technology makes screw to have evenly distributed force during fast injection, Five star Hydraulic motor with big torque. Ensure the excellent plastic molding condition. Research and develop different screws according to different injection condition, suitable for the progressive demand and greatly improve the injection quality

Control Unit

Imported computer special for Injection Molding Machine with multiple functions and precise control processing. World famous electrical components and high quality circuit hardware with stable and reliable running

No |

Name |

Brand /Material |

Origin |

1 |

Screw/barrel |

Ouwei/Fuyi/Tongda, 38CrMoAL |

China |

2 |

Three templates and injection head, second plate |

QT500 |

China |

3 |

Servo Motor |

Synmot |

China |

5 |

Hydraulic Motor |

Delson |

Italy |

6 |

Stroke Switch |

Honeywell/OMRON/Panasonic |

USA/Japn |

7 |

Air Switch |

SCHNEIDER//LG |

France/ Korea |

8 |

AC Contactor |

SCHNEIDER |

France |

9 |

Thermal relay |

SCHNEIDER |

France |

10 |

Controller |

TECHMATION |

Taiwan, China |

11 |

Electronic Ruler |

Jiesheng |

USA |

12 |

Pump |

Oufeite |

China |

13 |

Solenoid valve |

YUKEN |

Japan |

14 |

Oil seal/dust seal |

VALQUA/HALLITE |

Japan/UK |

15 |

KDAS wearing ring |

HALLITE |

UK |

16 |

Servo controller |

Mengde |

China |

One stage or Second stage R.O. Water treatment system

Raw Water Tank→ Raw Water Pump→ Quartz Sand Filter→Activated Carbon Filter→ 5 Micron Filter→ 1 Micron Filter→High Pressure Pump→Primary Reverse Osmosis Device→Intermediate Water Tank→ Booster Pump→ (Secondary High Pressure Pump→Secondary Reverse Osmosis Device) → Ozone Mixer→Pure Water Pump→ Pure Water Tank→ External Supply Pump→ Titanium Tube Filter→ External Supply→ To Filling Machine

Automatic OPP BOPP hot melt Glue labeling machine

Automatic BOPP labeling machine is widely suitable for different material of containers and labels. The cost of each label is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is one of the most economical models to make mass production and integrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, like changing the label is only needed to change the PLC program, the products concept that the equipment is used for users and considered for users is embodied in everywhere

Automatic PVC PE Sleeve Shrink Labeling Machine

This fully automatic sleeve labeling machine is suitable for various kinds of bottles, like round bottles, square bottles, oval bottles, etc. This machine can automatically feed and cut film, and it can sleeve labels precisely, greatly saving labor and improving work efficiency. The machine can be widely used for beverage bottles, cosmetic bottles, shampoo bottles, etc

Operating Principle Of Packaging Machine

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM