GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

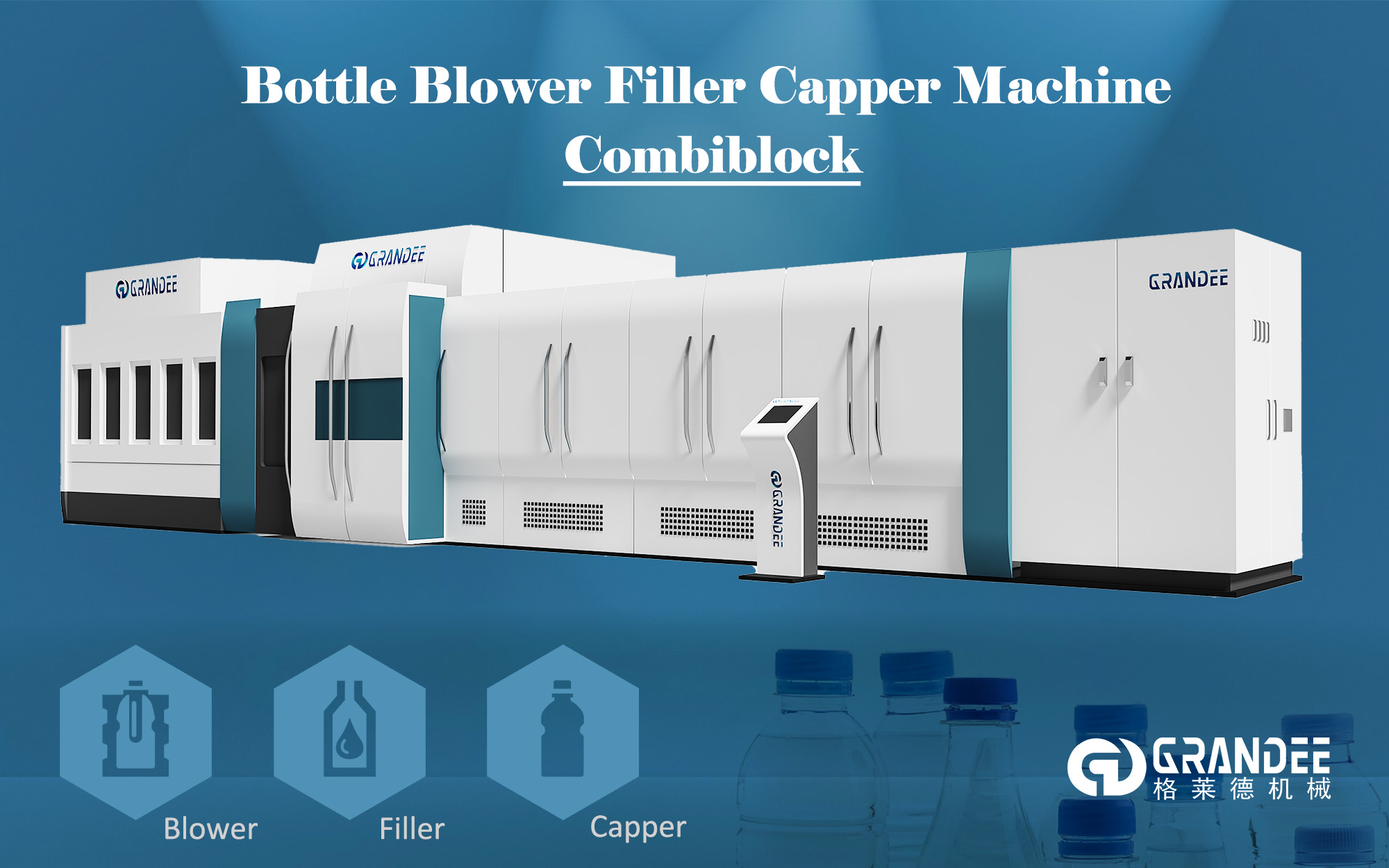

Bottle Blower Filler Capper Machine Combiblock

1. Advanced control system The CGX high-speed rotary fully automatic bottle blowing machine produced by our company uses a control system composed of SIMATIC HMI (human-machine interface), Siemens S7 series industrial control system (PLC system) and related control detection and actuator mechanisms. The entire system is stable reliable and responsive

2. Machine safety protection system Each torque point and key point of the machine has torque protectors, photoelectric protection switches, stroke protection switches and other protective measures, so as to ensure the safe operation of the equipment, avoid the forced operation of the robot, thus extending the service life of the machine and the maintenance cost of accessories

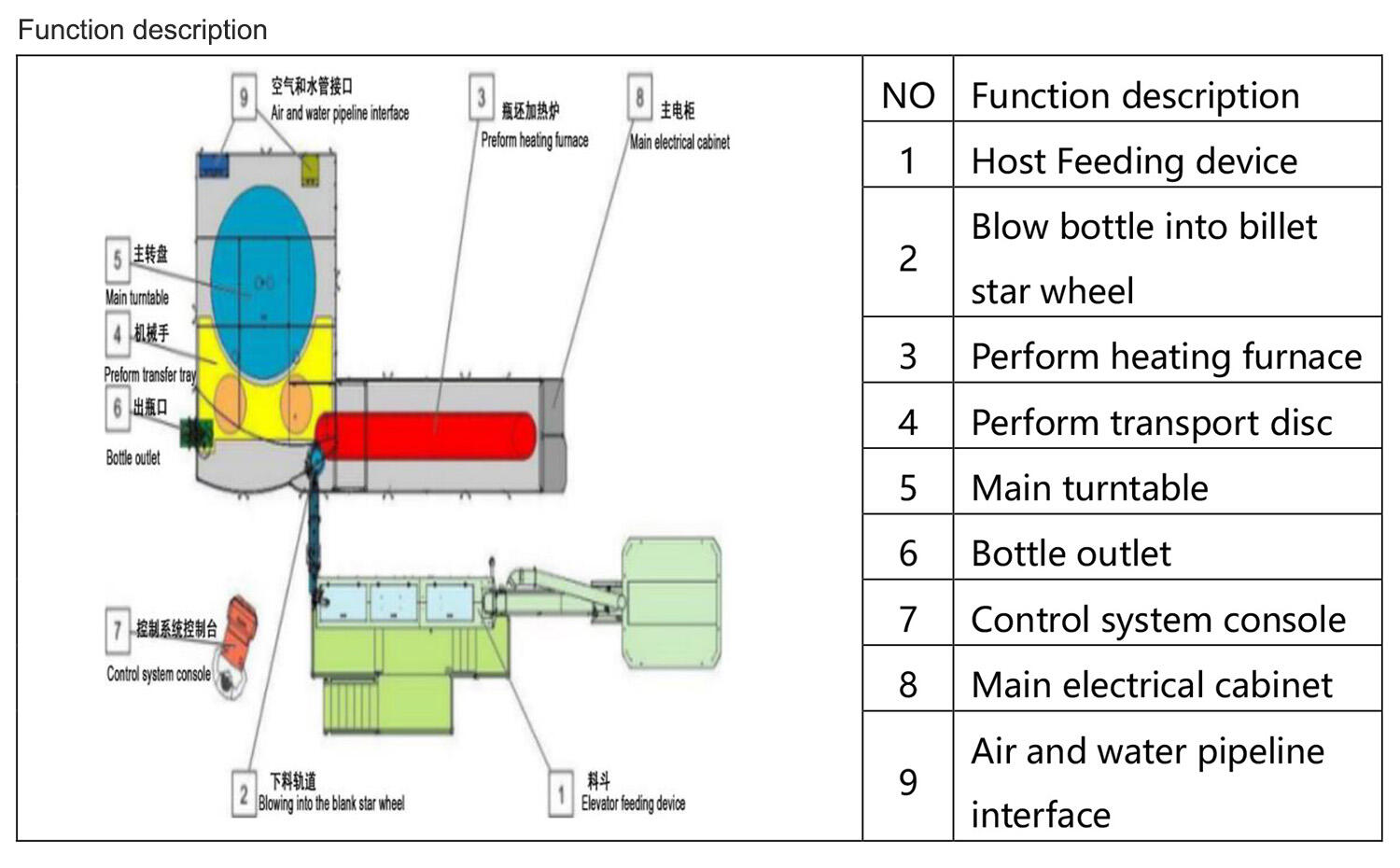

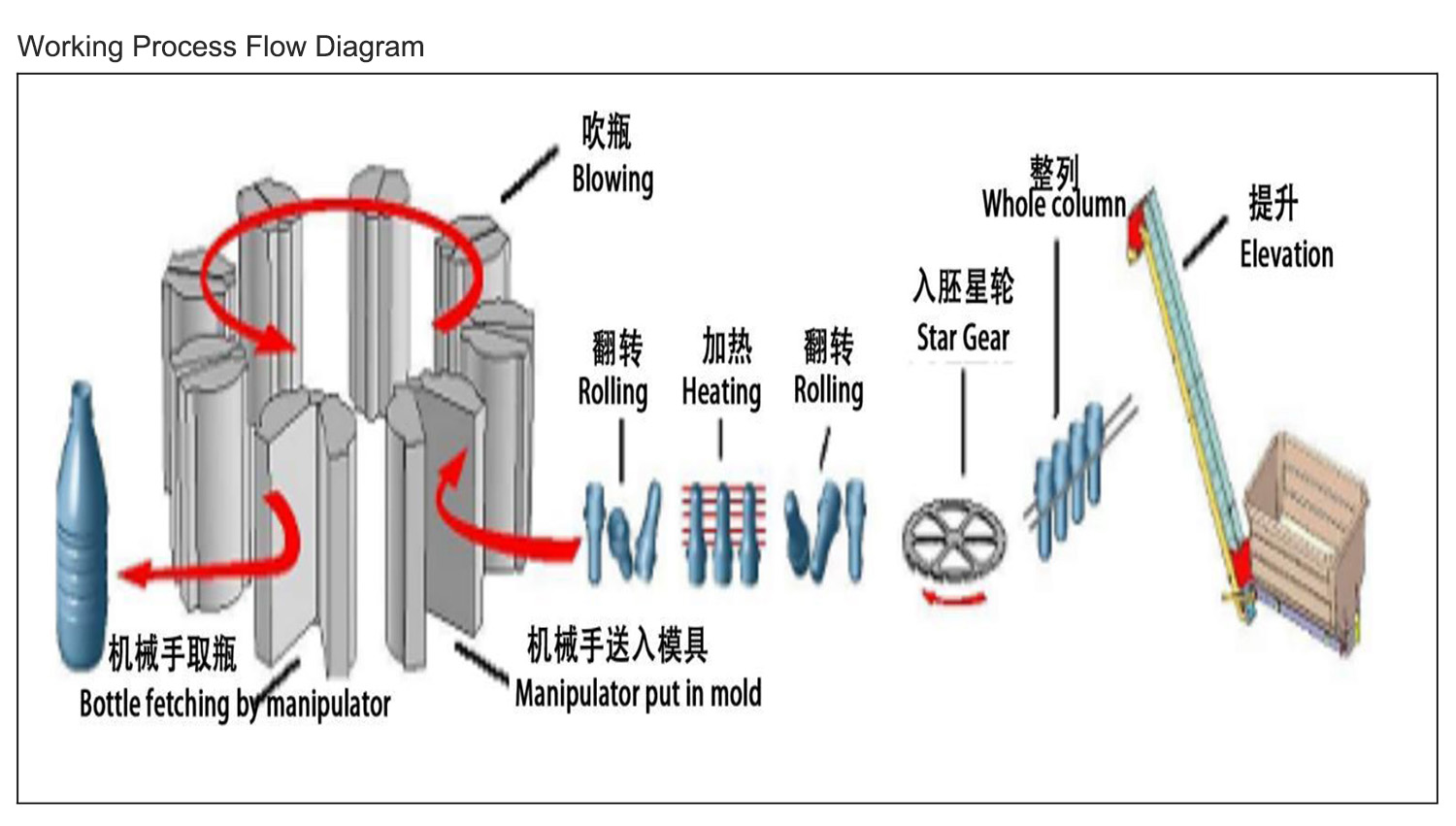

3. The appearance of the bottle blowing machine is shown in the figure The automatic rotary blowing machine is a high-speed two-step blowing machine successfully developed by our company to absorb the most advanced bottle making technology in the world today. The machine is mainly composed of automatic feeding device (hopper, lifting mechanism, whole mechanism feeding track), heating furnace, main blowing machine, electrical control system and pneumatic control system

NO. |

Model |

Capacity |

Bottle size |

1 |

8-24-8 |

12000BPH |

500ml |

2 |

8-32-8 |

15000BPH |

500ml |

3 |

8-40-10 |

16000BPH |

500ml |

4 |

12-42-10 |

18000BPH |

500ml |

5 |

16-40-15 |

24000BPH |

500ml |

6 |

20-60-18 |

36000BPH |

500ml |

|

|

|

Heads |

|

Filling machine: 72, capping: 15 |

|

Capacity |

|

24000BPH(600ml Carbonated drink bottle) |

|

Applicable bottle type |

|

PET bottle |

|

Applicable bottle type |

Bottle diameter range |

D=50~97mm |

|

|

|

Bottle height range |

H=150~310mm |

|

Compressed air consumption |

|

0.8m3/min(0.7MPa/h) |

|

Cooling water consumption |

|

3000L/h |

|

Cooling water temperature |

|

1-5℃ |

|

Working voltage |

|

380V,50HZ |

|

Control voltage(DC |

|

24V |

|

Cap torque |

|

0.6~2.8Nm(Adjustable) |

|

Power |

|

7.5KW |

|

Dimension(L*W*H) |

|

4276X3980X3100mm

(Subject to the final drawing) |

|

Weight |

|

About 12T |

|

1. Preform feed-in and unscrambler

It adopts the matured worldwide-standardized way of preform feed-in and unscrambling, in which preforms go through preform elevator and are transmitted to preform unscrambler. Inside the preform unscrambler, preforms are automatically sorted and delivered by two inclined revolving cylinders with same speed, and the remaining ones will be picked by star wheel and sent back to preform hopper. The whole process of preform unscrambling is fully automatic and has high efficiency without preform scratches

2. Bottle Preform Heater

It adopts the matured worldwide-standardized way of preform feed-in and unscrambling, in which preforms go through preform elevator and are transmitted to preform unscrambler. Inside the preform unscrambler, preforms are automatically sorted and delivered by two inclined revolving cylinders with same speed, and the remaining ones will be picked by star wheel and sent back to preform hopper. The whole process of preform unscrambling is fully automatic and has high efficiency without preform scratches

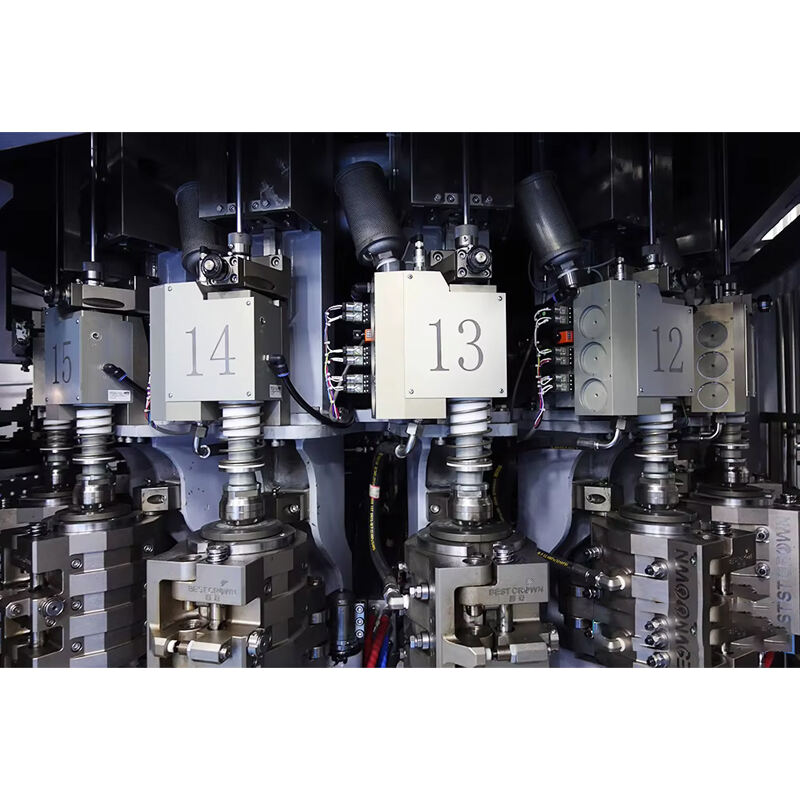

Introduction to the blowing machine

Introduction to the blowing machine The core parts, such as the sealing cylinder of the bottle blowing valve island, are all imported and customized by SEITZ. Blow bottle high pressure gas recovery is applied to low pressure gas needs. The inverted heating furnace structure saves energy by 15%. Bottle blowing has pressure detection and bad bottle rejection functions. The system running status can be monitored remotely. Using forged high-strength mold frames, the equipment operates efficiently and stably. The equipment's running track cam is patented, with low vibration, low noise, and stable and reliable operation

Automatic blow molding machine mold

The mold is an important factor affecting the PET bottle blow molding process, and the shape of the mold will reduce or increase the difficulty of process adjustment. For example, the reinforcement, the arc of the transition zone and the heat dissipation condition at the bottom have an impact on the process adjustment and directly affect the quality of the bottle, so we recommend that customers pay attention to the novel and unique product packaging and beautiful at the same time, take into account whether the selected bottle type can meet the requirements of use, it is best to be reviewed by our professional designers When the mold is customized, it is mainly necessary to clarify the material and installation size. Make product capacity height requirements

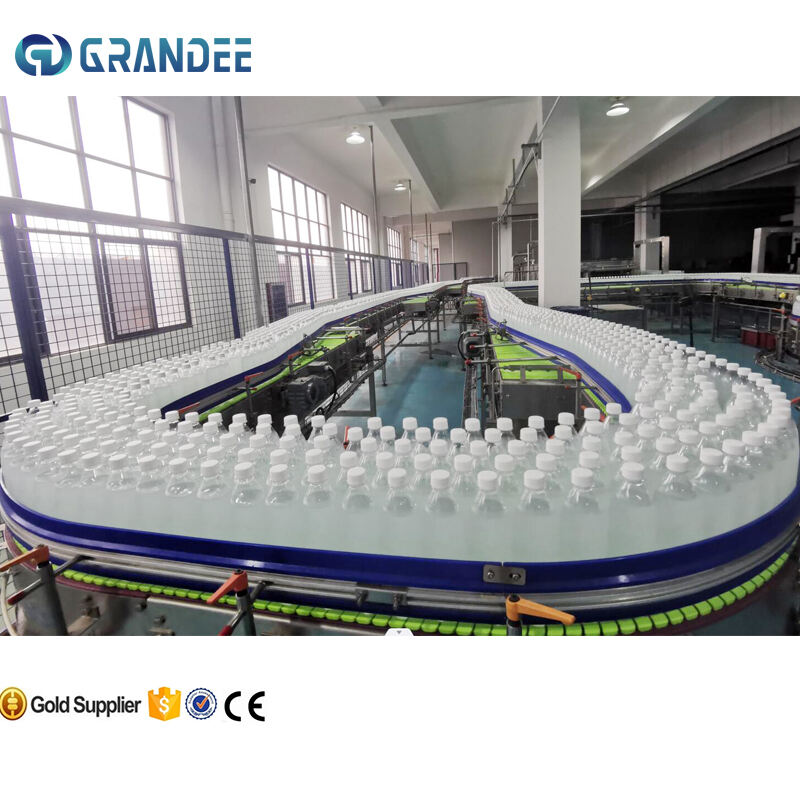

Lubrication System for Conveyor

The spray conveyor belt lubricant, suitable for food, water, beverage, beer, condiments and other industries packaging conveyor belt chain plate lubrication

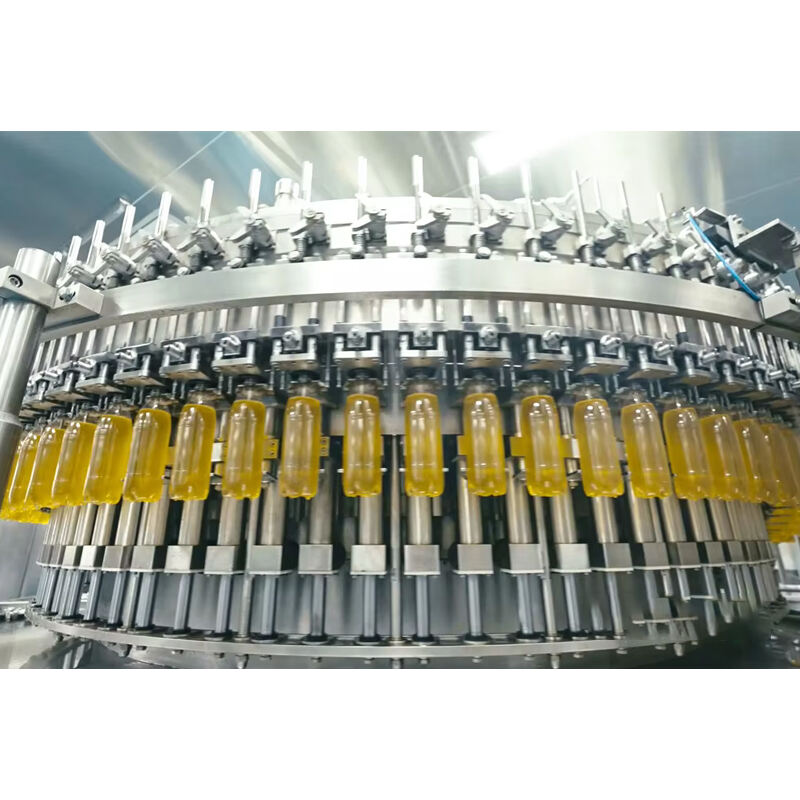

Fruit juice filling machine

|

Item |

Data |

1 |

Power |

15KW(will be changed according to different models) |

2 |

Robot |

KUKA, ABB, NACHI |

3 |

Max load per pallet |

1.6tons (will be changed according to different models) |

4 |

Pallet size |

1200x1000mm(can be customized according to customer requirements) |

5 |

speed |

10-80packs/min(the pallet speed is related to the size of the pallet and the grouping form of each layer) |

6 |

Pallet |

or plastic |

7 |

Overall size |

(L)8000MMx(W)4500MMx(H)3000MM(will be changed according to different models) |

8 |

Machine weight |

4500KG(will be changed according to different models) |

GRANDEE MACHINE

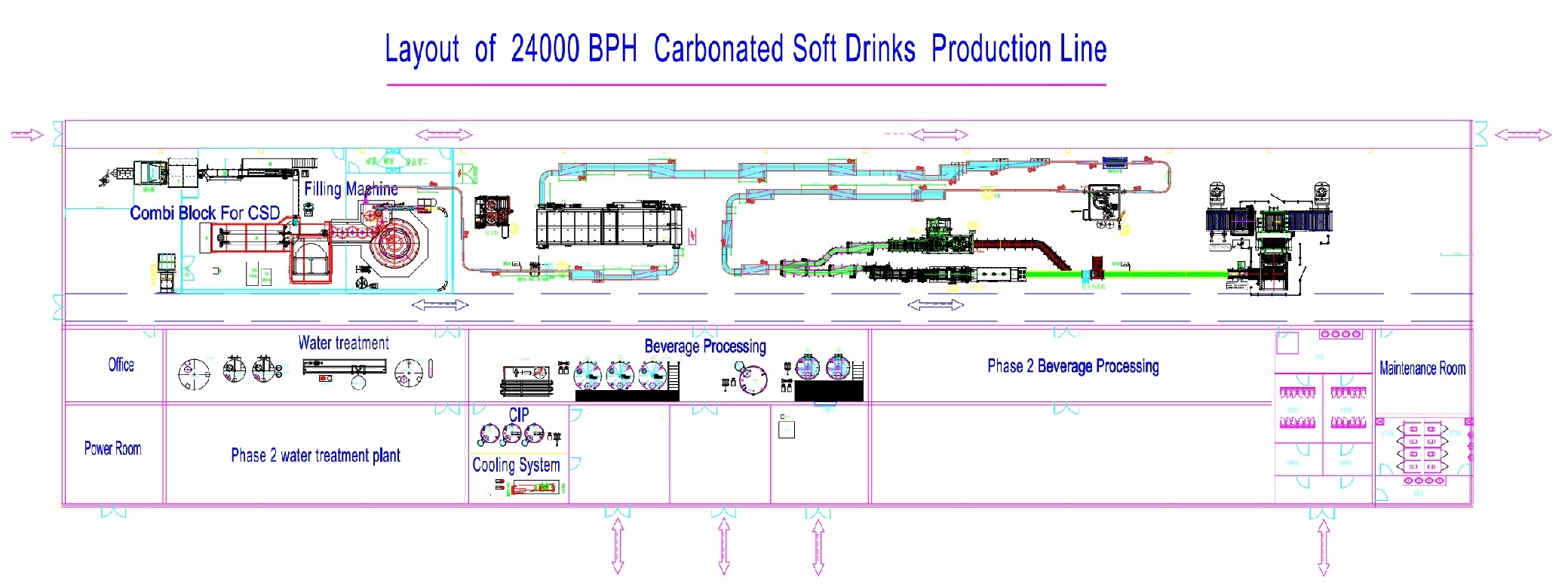

Introducing the most advanced carbonated soft drink production line from the Automatic Combi block Blowing Filling Capping Machine for sparkling water production.

with this machine is innovative it is possible to create top-notch carbonated drinks with ease and accuracy. It features a fully automated process that takes care of the manufacturing is entire, from container blowing to capping. The combi block technology simplifies the production process, reduces wastage, and ensures product persistence.

Comes with a container is high-speed system that produces animal bottles in different sizes and shapes. You'll customize the container design to suit your product and brand name needs. The GRANDEE MACHINE containers are then conveyed to the filling station, where they are filled with carbonated water or non-alcoholic drink mix at a rate is managed. The level is filling accurately measured and adjusted to eradicate overfilling or under filling.

After filling, the containers move to your capping station, where they are sealed with screw caps or caps Snap-On. The capping system is designed to manage different cap sizes and styles and guarantees a secure and seal is tight. The caps are carefully torqued to avoid leakage and guarantee item freshness.

Built with high-quality materials and components that guarantee reliability and durability. It is possible to operate, having an interface is user-friendly allows you to set different parameters and adjust the production speed. The device is loaded with safety features that protect operators and stop accidents.

with this particular automatic carbonated drink is soft line, you can increase your manufacturing ability, reduce work costs, and improve product quality. It would work for small to medium-sized beverage is soft sparkling water production companies. It comes down by having a warranty is one-year after-sales support to make sure customer satisfaction.

The Automatic Combi block Blowing Filling Capping Machine from GRANDEE MACHINE is a game-changer in the carbonated soft drink production industry. It offers speed, precision, and flexibility, All in one machine. Invest in this high-tech machine today and take your soft drink production to the next level.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM