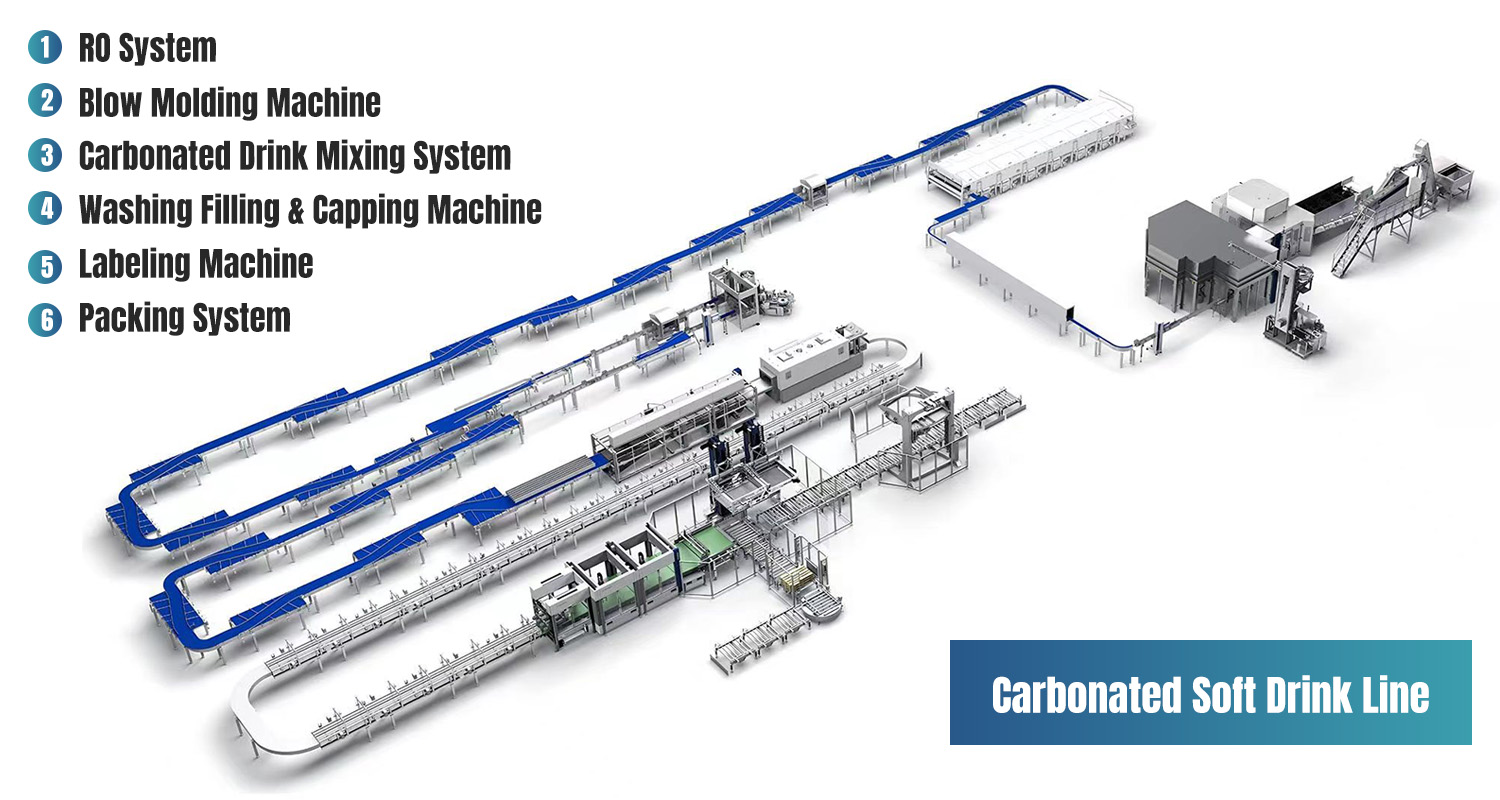

Launching the GRANDEE MACHINE Automatic Carbonated Beverage Filling Machine – the solution ideal all of your carbonated drink filling needs! This top-of-the-line can machine filling engineered with accuracy to provide a hassle-free and option efficient bundle your chosen carbonated beverages

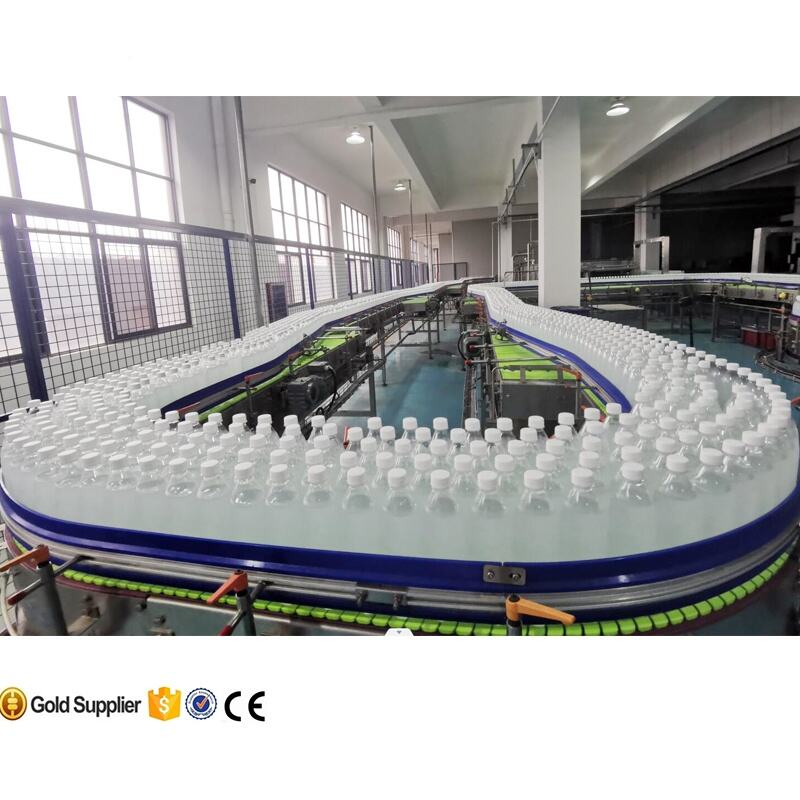

You streamline your drink manufacturing procedure whether you may be a small company owner, a drink supplier, or perhaps a large drink maker, this might filling machine may help The machine is straightforward to use, as well as its features being completely automated it perfect for filling cans of various shapes and sizes Along with the GRANDEE MACHINE Automatic Carbonated Beverage Filling Machine, you shall not need to be worried about filling mistakes, since the machine was made to fill your cans accurately and regularly

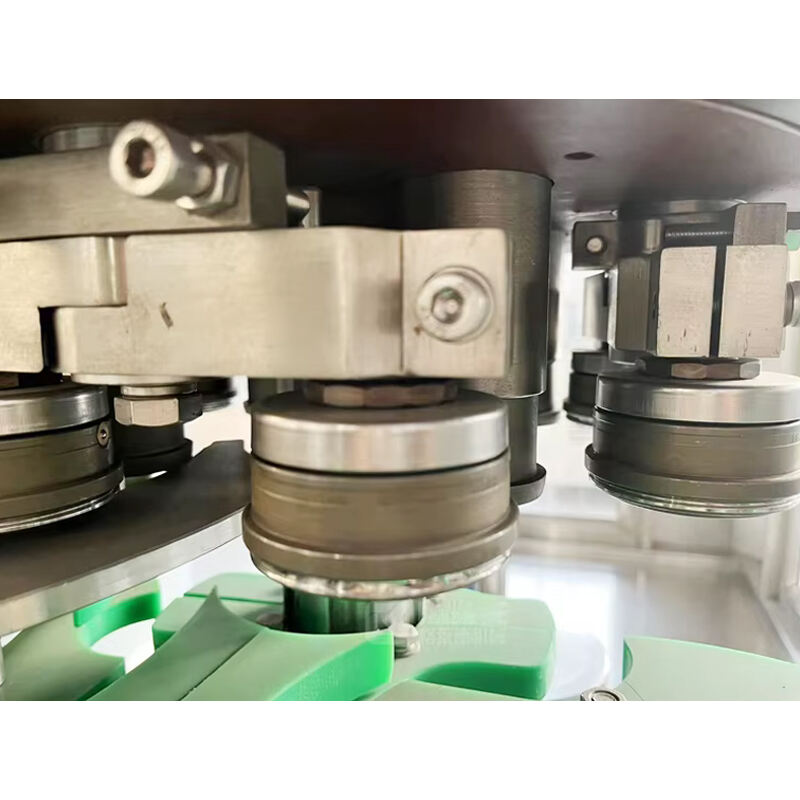

The machine additionally includes a construction robust durable elements that guarantee long-lasting usage and dependability It is made from top-quality metal stainless make certain that it is resistant to rust and corrosion Also, it boils down having a conveyor high-speed designed to manage big levels of cans simultaneously, assisting you save hard work Moreover, the machine's stuffing nozzles are made of top-grade materials which is often corrosion effortless and resistant to clean

This carbonated drink machine filling additionally made with your security in mind It boils down insurance firms an array of security features, for example security overload overheat protection, and crisis end buttons to avoid accidents while making sure your satisfaction Moreover, it runs quietly, reducing pollution sound making a relaxed, more work place calm

One of several better top attributes of the GRANDEE MACHINE Automatic Carbonated Beverage Filling Machine is its flexibility It can be useful to fill types of sodas, including soda pops, energy drinks, and carbonated water Also, it might work effortlessly with different container sizes, starting from 150 ml to 500 ml

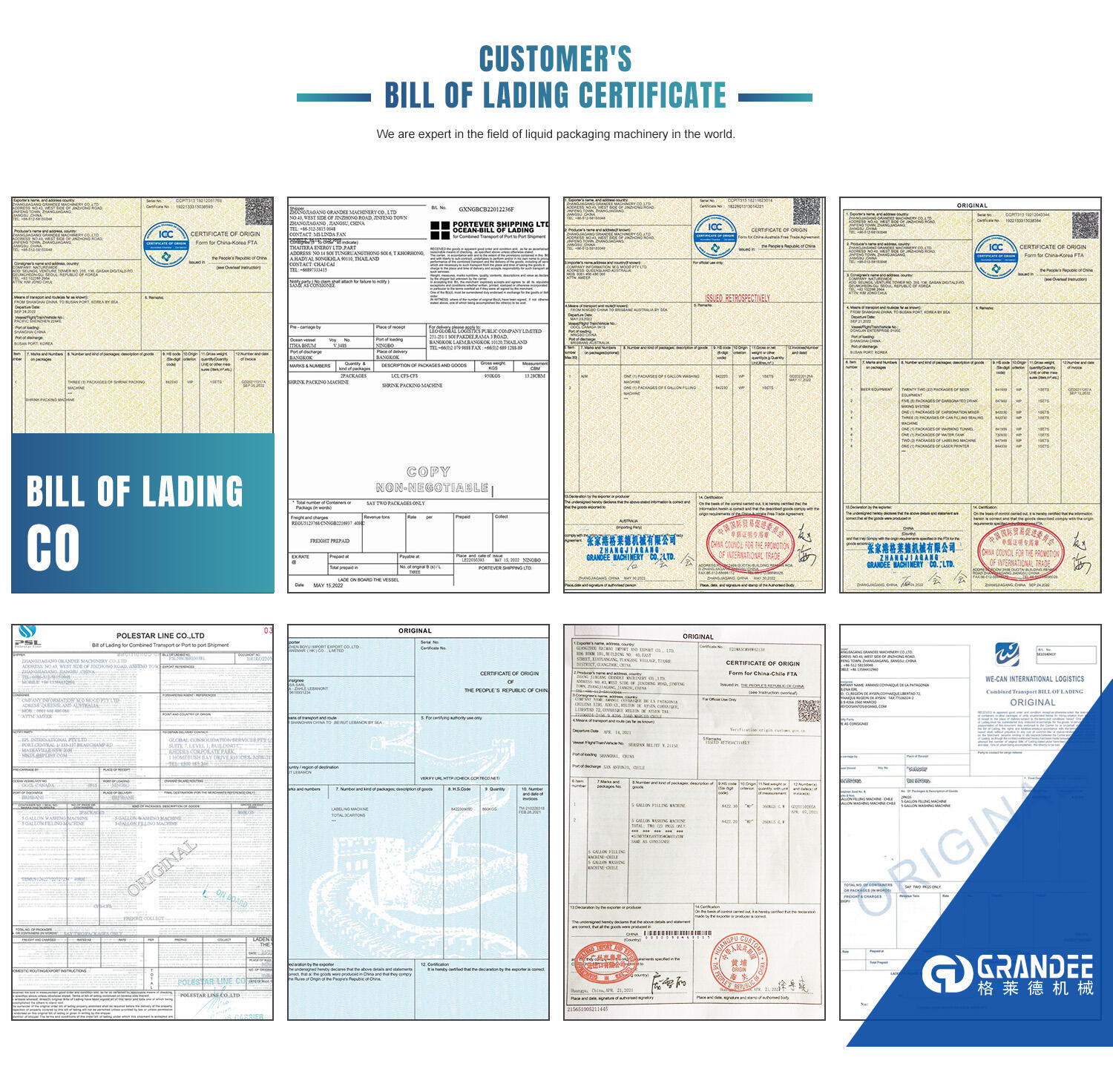

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

Carbonated Beer Can Filling Sealing Machine

Beer canning machine / soda water filling sealing machine for equal pressure can filling sealing machine of carbonated drinks in beer and drink industry. It is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and pneumatic control technology. It has the characteristics of filling fully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers’ request. It is the preferred equipment for the medium beer and beverage plant.

Auto pallet → Automatic can rinsing machine→Automatic soda water can filling machine→

Automatic can sealing machine→Can warmer(optional)→Blow dryer→Automatic or Manual sleeve labeling machine→Bottle Collection Table

Automatic lifting and unloading machine:

Production capacity: 200-400 cans/min Applicable tank diameter: 52-153mm Applicable tank height: 39-170mm Push can form: automatic push can, mesh belt conveyor Tank discharging form: multi - row to single - row conveyor belt out of tank Stacking form: manual button control

Automatic can washing part:

Adopt many rows of washing can machine, can driven by many rows conveyor into the washing cans equipment, after finishing washing and through stranding cage overturning, and then to the filling capping equipment.

Filling part

Adopt PLC, frequency converter and man-machine interface control system. It has advanced control technologies such as variable frequency speed regulation, automatic filling with cans, no filling without cans, etc. Through various sensors on the device, the accurate production speed and production quantity can be displayed on set it on the touch screen.

Sealing part

The finished cans are sent to the sealing machine head via a hook chain, and the lid is sent to the mouth of the tank through the cap feeder. When the can supporting mechanism is raised, the indenter presses the mouth of the can, and the sealing wheel is pre-sealed and sealed. After the can is sealed, it is pushed out by the canning mechanism to complete the process of filling and sealing

Electrical control

HMI and PLC: SIEMENS, GERMANY

Frequency converter: Schneider, French

|

Model

|

|

|

|

|

|

DXGF

50-50-12

|

|

|

|

|

|

Capacity (500ml)

|

|

|

|

|

|

12000-14000

|

|

|

|

|

|

Filling type

|

Isobaric filling

|

|

|

|

|

|

|

Filling pressure

|

<0.4MPa

|

|

|

|

|

|

|

Rinsing water pressure

|

>0.06MPa <0.2MPa

|

|

|

|

|

|

|

Application

|

Carbonated soft drink bottling line

|

|

|

|

|

|

|

Totalpower

|

2.5kw

|

3.7kw

|

6kw

|

7.5kw

|

8.2kw

|

11kw

|

|

|

|

|

|

Overall dimensions

|

2.0*1.9m

|

2.3*1.9m

|

2.6*2.15m

|

2.8*2.5m

|

3.6*2.3m

|

5.5*3.3m

|

|

|

|

|

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

|

|

|

|

|

Weight

|

2000kg

|

2500kg

|

4000kg

|

4500kg

|

6000kg

|

11000kg

|

|

|

|

|

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

Automatic soft drink filling machine

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line, can filling and sealing line, complete blowing labeling and packaging system

Q1: How to find suitable machine or complete beverage production line?

A1: Looking for beverage filling machine in www. grandee machine. en. alibaba. com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team, providing good and after-sales service term, professional salesman terms

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee, and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM