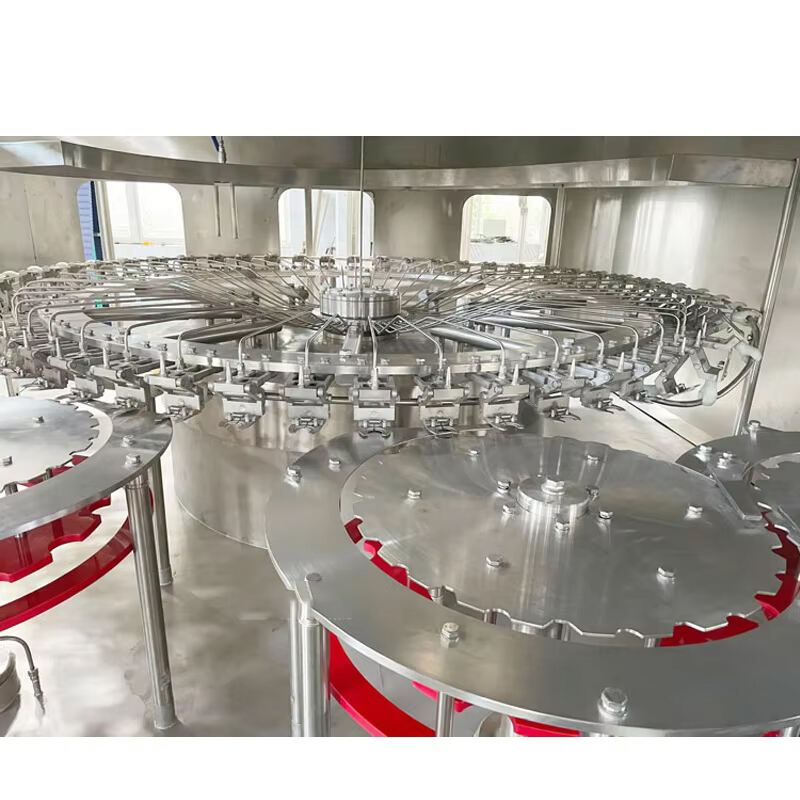

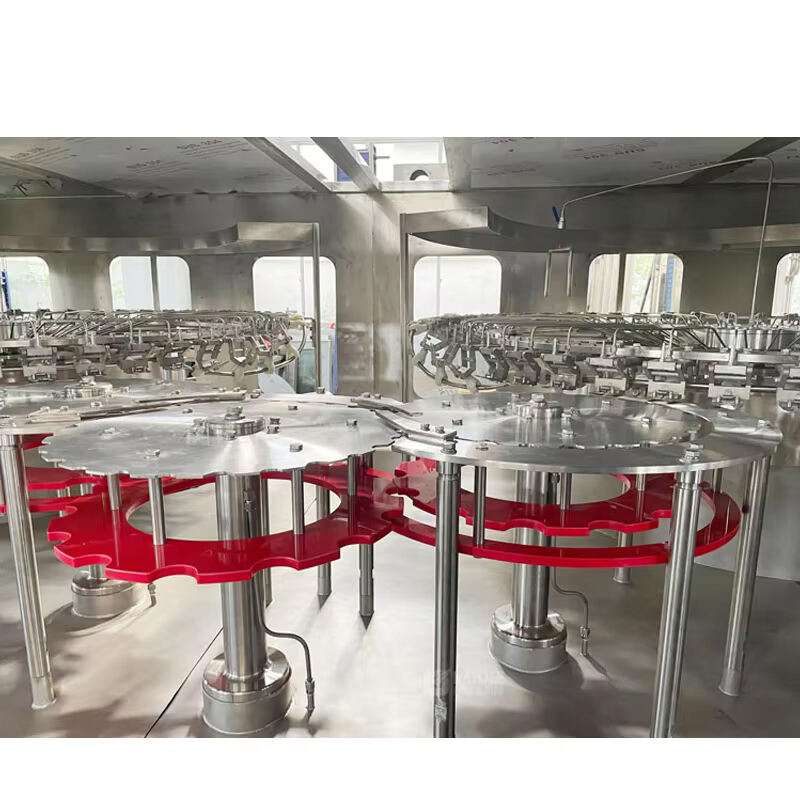

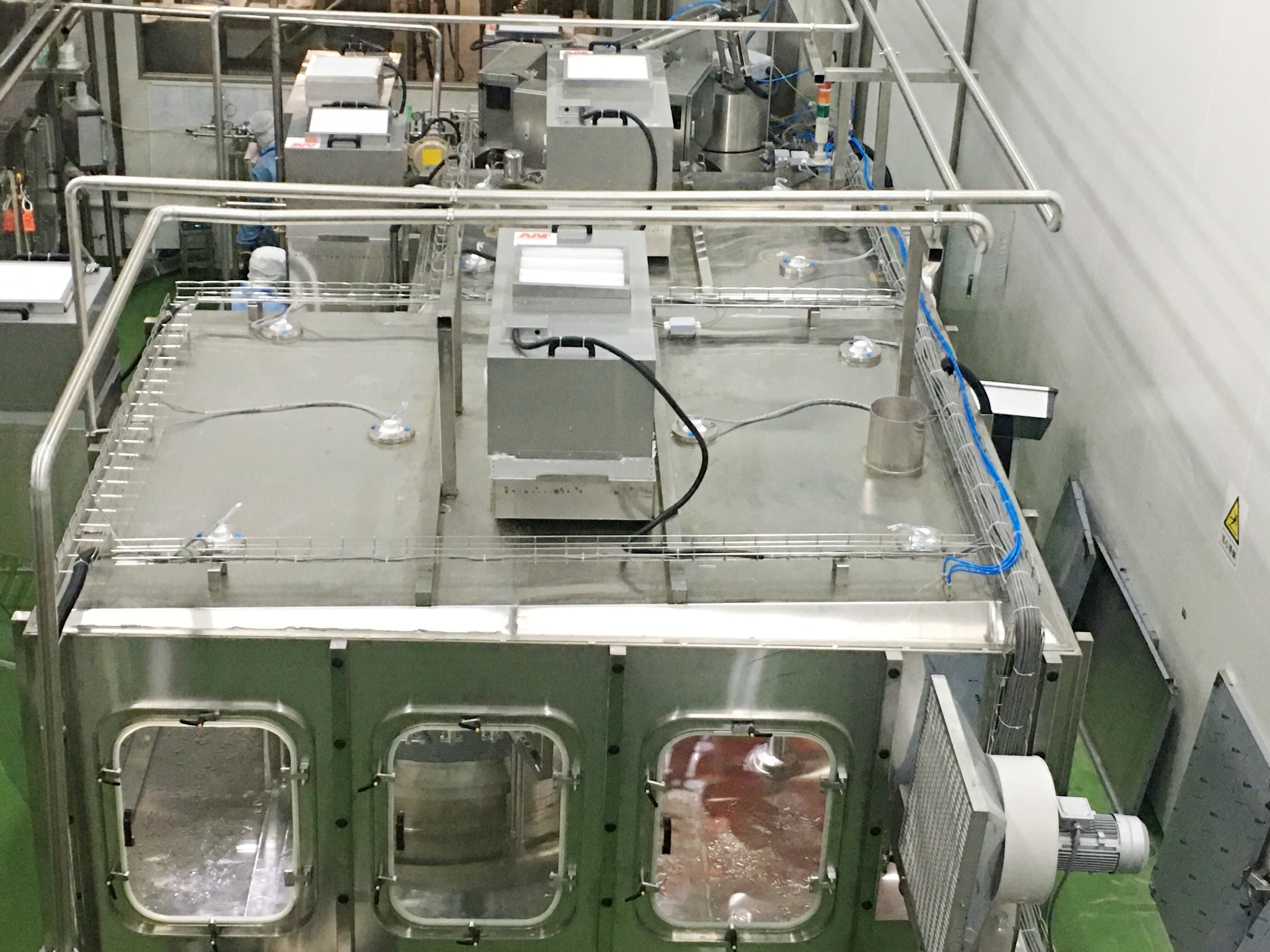

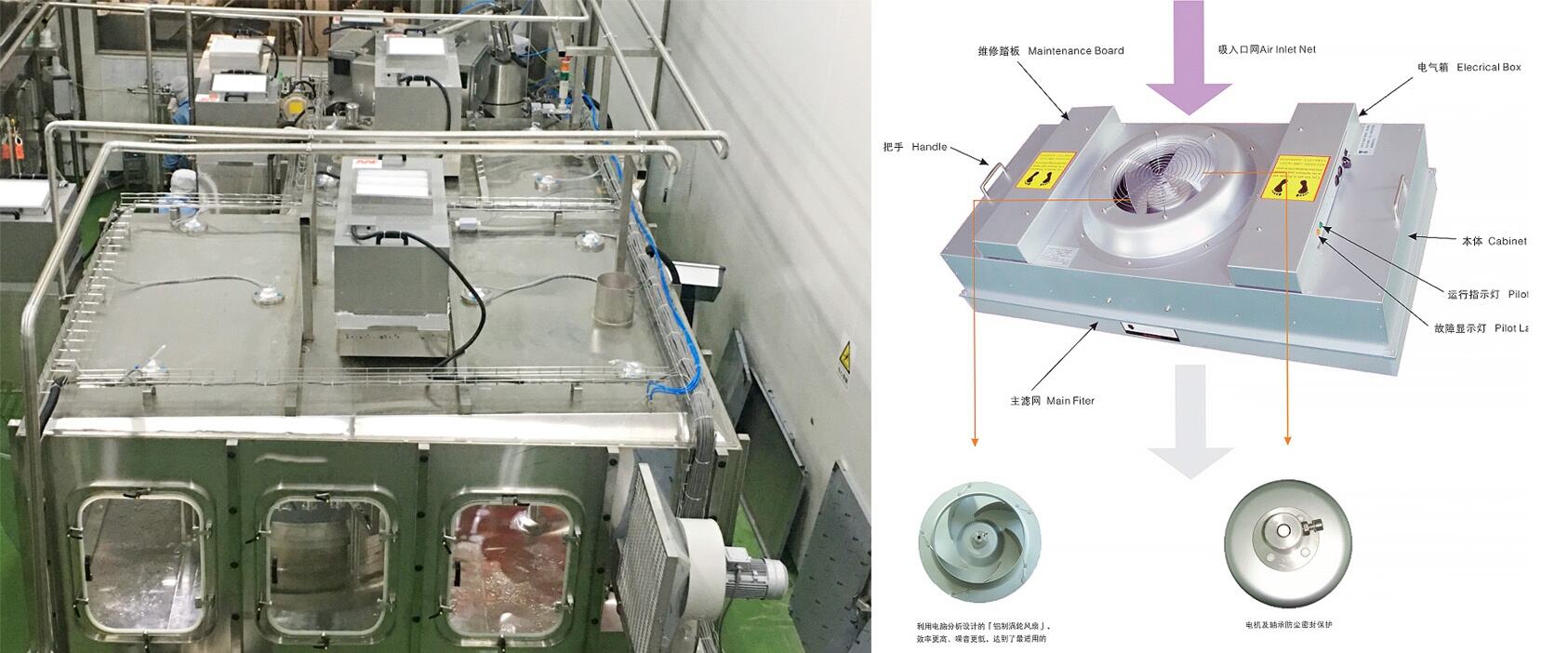

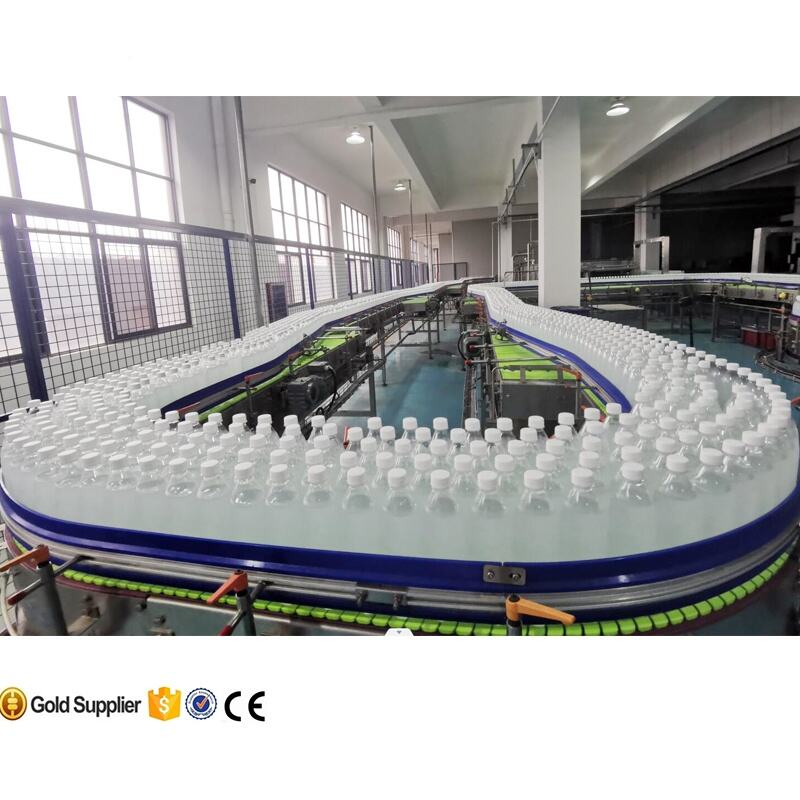

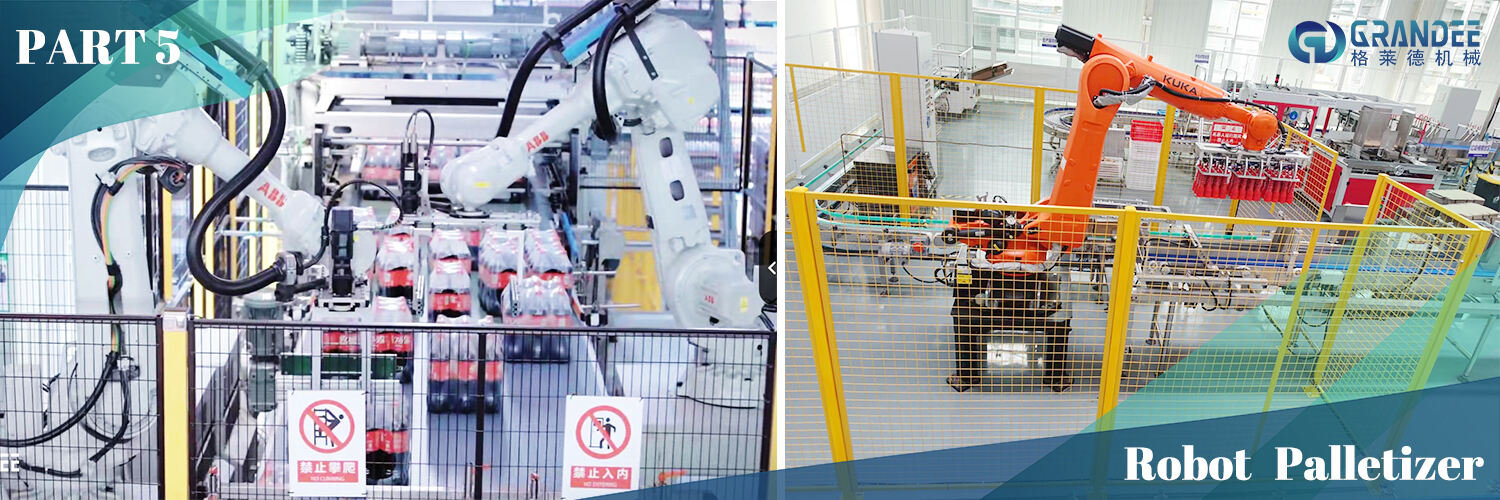

Automatic 5 in 1 Aseptic cold coconut water milk NFC juice washing washing washing filling capping machine production line

ZXXGF24-24-16-16-5 PET bottle disinfection, disinfection, aseptic water washing, filling, capping machine, adopt the advanced technology, stable performance, safe and reliable. (It can produce like NFC juice, milk, vitamin drinks and other plant-based drinks). The filling machine adopts non-contact filling method, which can effectively prevent secondary pollution; The filling valve adopts the pneumatic diaphragm filling valve imported from Germany, and the filling capacity is measured with the imported high-precision electromagnetic flowmeter to realize the opening and closing of the valve. The working environment of the host should be selected as aseptic isolation system, aseptic maintenance gloves, aseptic item transfer device, automatic foam cleaning system, disinfectant spray fumigation syste

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM