Grande Machine

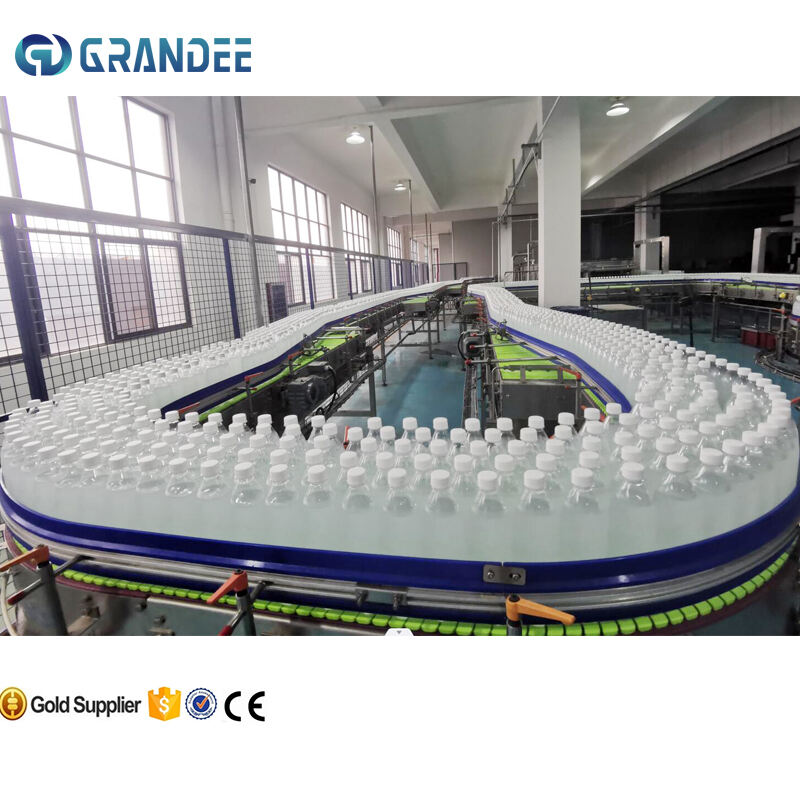

Introducing the Automatic 3 in 1 and 4 in 1 mineral water filling machine, the newest addition to the product line. Our machine is designed to automate the entire mineral water bottling process, making it an efficient and cost-effective option for businesses looking to increase their production output.

The 3 in 1 mineral water filling machine is equipped with three main functions - washing, filling, and capping. The machine is capable of handling a wide range of bottle sizes and shapes, making it suitable for small and large-scale manufacturing operations. With its automatic controls and high-speed filling capabilities, the GRANDEE MACHINE 3 in 1 machine is sure to increase your production efficiency and reduce labor costs.

For those looking for an all-in-one solution, the 4 in 1 mineral water filling machine is the perfect fit. It comes with an additional labeling function that allows businesses to print and attach labels to their water bottles, streamlining the entire bottling process. Our 4 in 1 machine is also an excellent option for businesses looking to reduce their carbon footprint, as it uses eco-friendly materials that are both biodegradable and recyclable.

Our Voss mineral water bottling plant is designed to meet the specific needs of businesses looking to manufacture premium mineral water at an affordable cost. Our plant is capable of producing high-quality water that meets stringent international standards, making it perfect for businesses looking to establish themselves in the competitive bottled water market.

The drinking bottled water production system is designed to integrate seamlessly with the Grande Machine mineral water filling machines. The system is equipped with advanced filtration systems that remove impurities and contaminants, ensuring that the water produced is clean and safe for consumption. The system is also designed to be energy-efficient, reducing your energy costs while producing high-quality water.

At Grande Machine, we take pride in our commitment to quality and efficiency, which is why all our products are designed to meet international standards. Our Automatic 3 in 1 and 4 in 1 mineral water filling machine, Voss mineral water bottling plant, and drinking bottled water production system are no exception.

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

Mineral Pure Water 4 in 1 Filling Production Machine

(1) Water filling line/liquid filling line includes: Washing-filling-capping-capping 4 in 1 machine, lamp inspection, label shrinking machine, inkjet printer, hot shrink film packer and conveyors. It is a full automatic production line.

(2) The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

Washing machine part

The grippers take the bottles from the inlet star-wheel while they are still driven by the star-wheel, thus guaranteeing a safe grip. After the gripping, the bottle is turned upside down with 180 degree and cantered above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again.

Filling machine part

Long tube filling type with 2 times filling process to make sure perfect filling level Liquid tank, filling valves, controlling rings, upgrading cylinder. High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

Screw capping machine part 1 ( small screw cap)

Rotative capping turret, suitable to the application of screw plastic caps on PET bottles The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads. The heads are raised and lowered by the action of a follower that is riding on a shaped cam.

Automatic capping machine 2 ( pressure type big cap)

Through the mechanical device or power drive, the capping head exerts pressure on the bottle cap, and the bottle cap is tightly pressed on the bottle mouth to achieve the purpose of sealing. This capping machine is fully automatic, with a total of 5 heads. When the small cap is screwed, enter the capping machine and press the big cap on the small lid. The cap mold of the big cap is customized according to the shape of the cap.

Dimension(mm) 1650*1350*2300mm

Main motor of automatic cap loader(KW) 0.4kw

Weight(KG) 400KG

Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity(500ml/BPH) |

2000-3000 |

3000-4000 |

4000-5000 |

6000-8000 |

10000-12000 |

13000-15000 |

16000-18000 |

23000-25000 |

30000-32000 |

|

|

|

|

|

|

|

|

Suitable bottle shape and size |

Both round of square bottle, 220ml-2000ml, Dia: 50-108mm, Height: 150-340mm |

Both round of square bottle, 220ml-2000ml, Dia: 50-108mm, Height: 150-340mm |

|

|

|

|

|

|

|

Compressed air pressure |

|

0.3-0.7MPa |

|

|

|

|

|

|

|

Bottle washing medium |

|

Sterile water |

|

|

|

|

|

|

|

Washing pressure |

|

|

|

|

|

|

|

|

|

Main motor |

1.5 |

2.2 |

2.2 |

3 |

4.5 |

5.5 |

7.5 |

11 |

17 |

|

|

|

|

|

|

|

|

|

2000*1600*2300 |

2200*1800*2300 |

2400*1900*2300 |

2400*1900*2350 |

2700*2100*2300 |

2970*2260*2700 |

3780*2800*2700 |

5500*3300*2700 |

6500*4800*2700 |

|

|

|

|

|

|

|

|

Weight(KG) |

2000 |

2500 |

3000 |

3500 |

4500 |

6500 |

8500 |

12800 |

15000 |

|

|

|

|

|

|

|

|

NAME |

BRAND |

AREA |

PLC |

Siemens |

Germany |

CONTACTOR |

Siemens |

Germany |

TOUCH SCREEN |

Siemens |

Germany |

INVERTER |

Siemens |

Germany |

MOTOR |

ABB |

SWISS |

PNEUMATIC PARTS |

FESTO |

GERMANY |

ELECTRICAL PARTS |

SCHNEIDER |

FRANCE |

Automatic OPP BOPP hot melt Glue labeling machine

Automatic BOPP labeling machine is widely suitable for different material of containers and labels. The cost of each label is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is one of the most economical models to make mass production and integrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, like changing the label is only needed to change the PLC program, the products concept that the equipment is used for users and considered for users is embodied in everywhere.

Automatic PVC PE Sleeve Shrink Labeling Machine

This fully automatic sleeve labeling machine is suitable for various kinds of bottles, like round bottles, square bottles, oval bottles, etc. This machine can automatically feed and cut film, and it can sleeve labels precisely, greatly saving labor and improving work efficiency. The machine can be widely used for beverage bottles, cosmetic bottles, shampoo bottles, etc.

Operating Principle Of Packaging Machine

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM