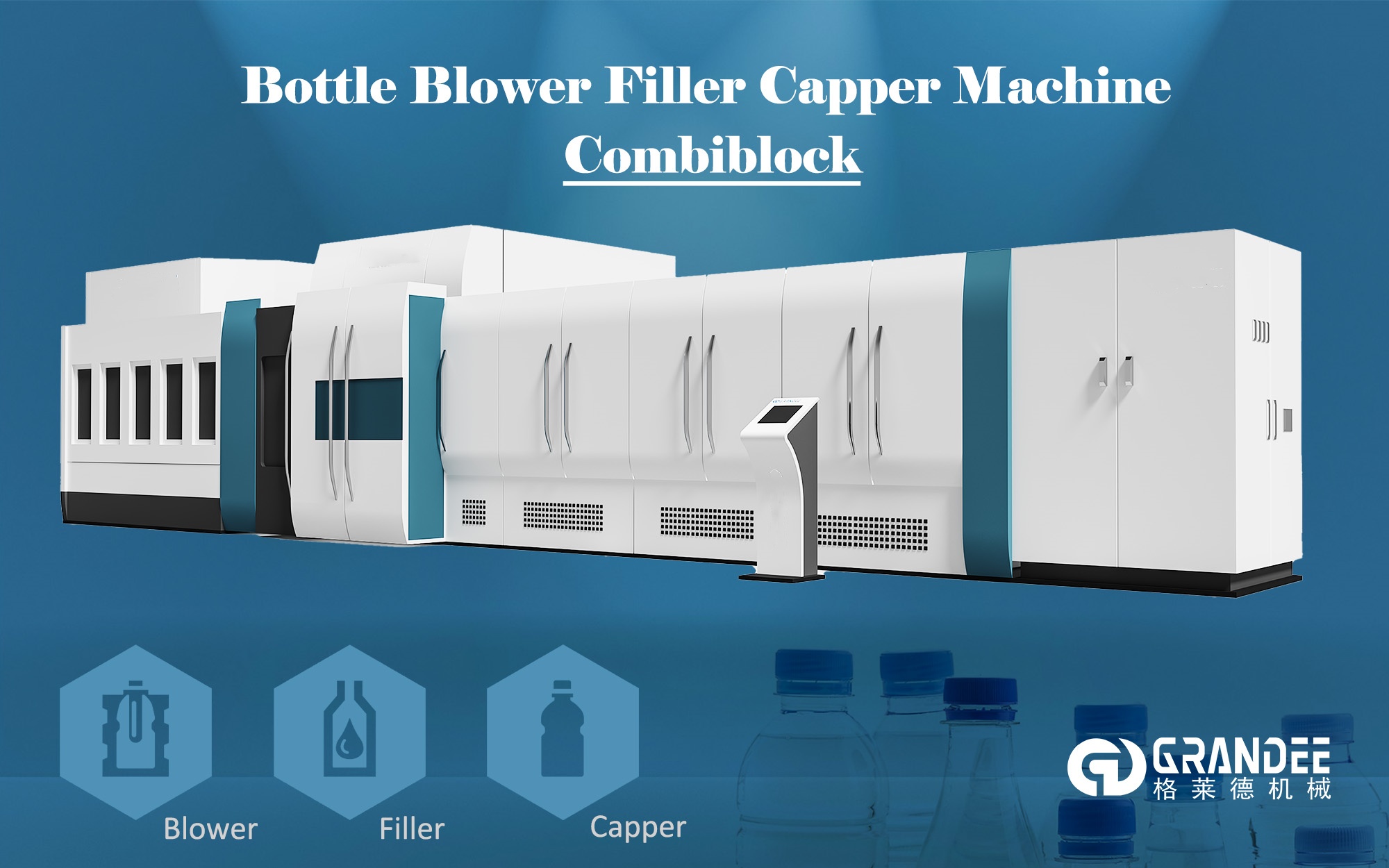

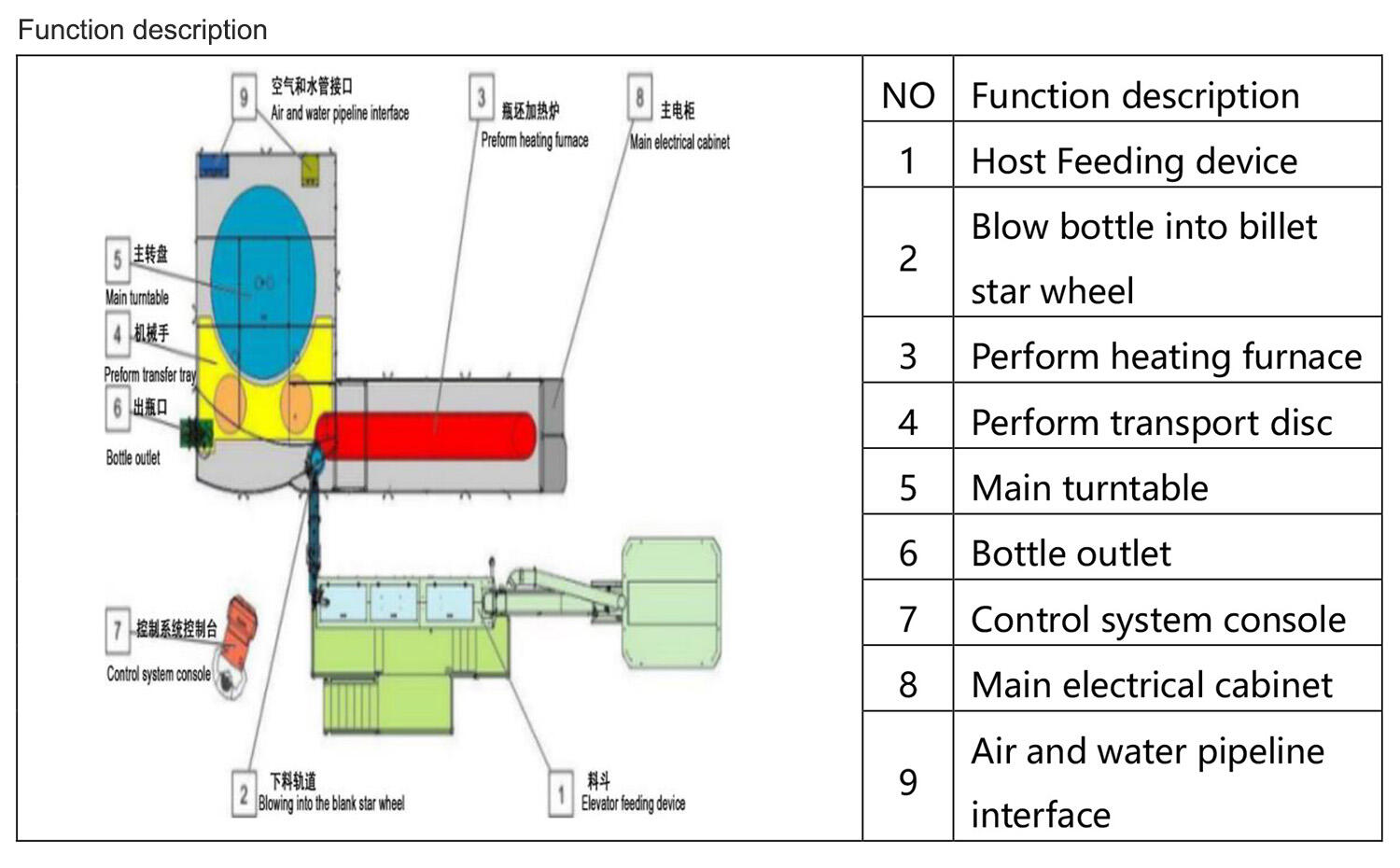

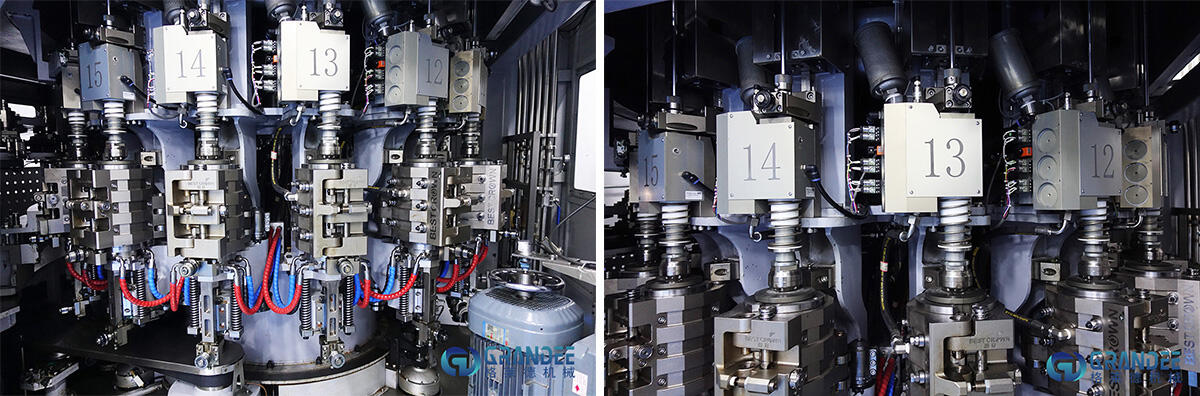

1. Advanced control system CGX high-speed rotary fully automatic bottle blowing machine produced by our company uses a control systemmposed of SIMATIC HMI (human-machine interface), Siemens S7 series industrial control systemLC system) and related control detection and actuator mechanisms. The entire system is stable reliable and responsive

2. Machine safety protection system

Each torque point and key point of the machine has torque protectors, photoelectric protection switches, stroke protection switches and other protective measures, so as to ensure the safe operation of the equipment, avoid the forced operation of the robot, thus extending the service life of the machine and the maintenance cost of accessories

3. The appearance of the bottle

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM