GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

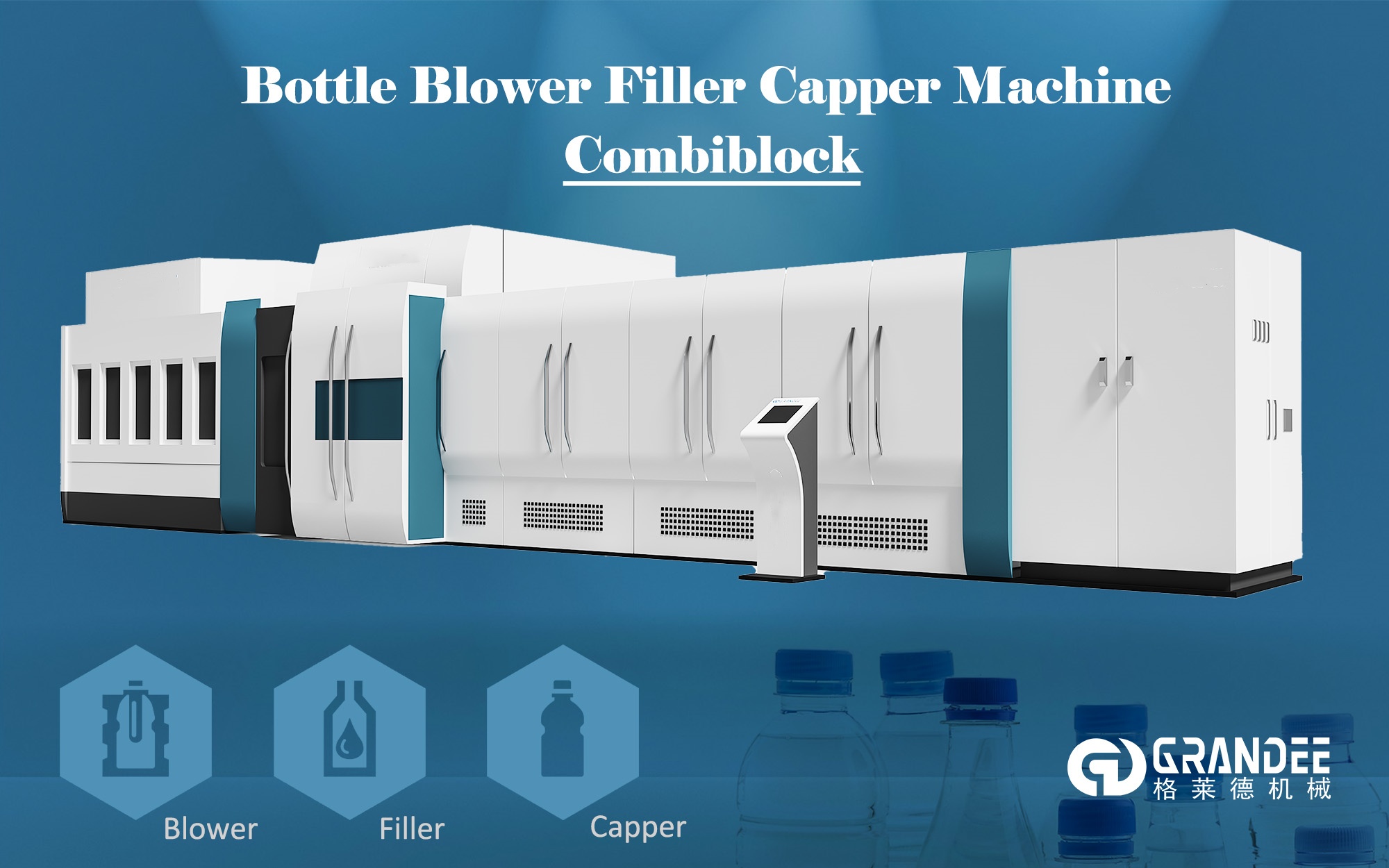

Bottle Blower Filler Capper Machine Combiblock

1. Advanced control system The CGX high-speed rotary fully automatic bottle blowing machine produced by our company uses a control system composed of SIMATIC HMI human-machine interface, Siemens S7 series industrial control system PLC system and related control detection and actuator mechanisms. The entire system is stable reliable and responsive

2. Machine safety protection system Each torque point and key point of the machine has torque protectors, photoelectric protection switches, stroke protection switches and other protective measures, so as to ensure the safe operation of the equipment, avoid the forced operation of the robot, thus extending the service life of the machine and the maintenance cost of accessories

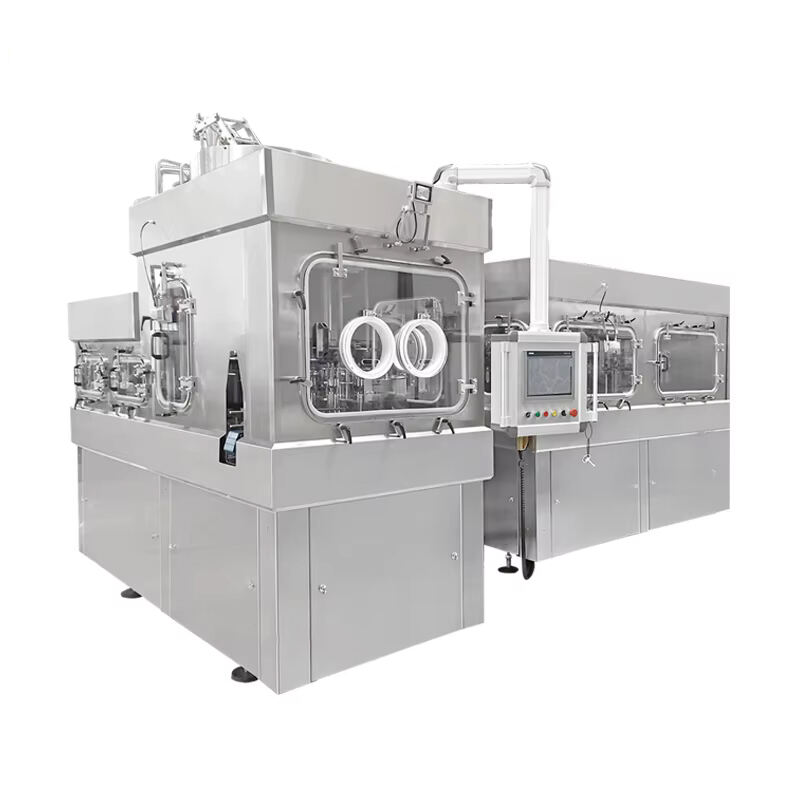

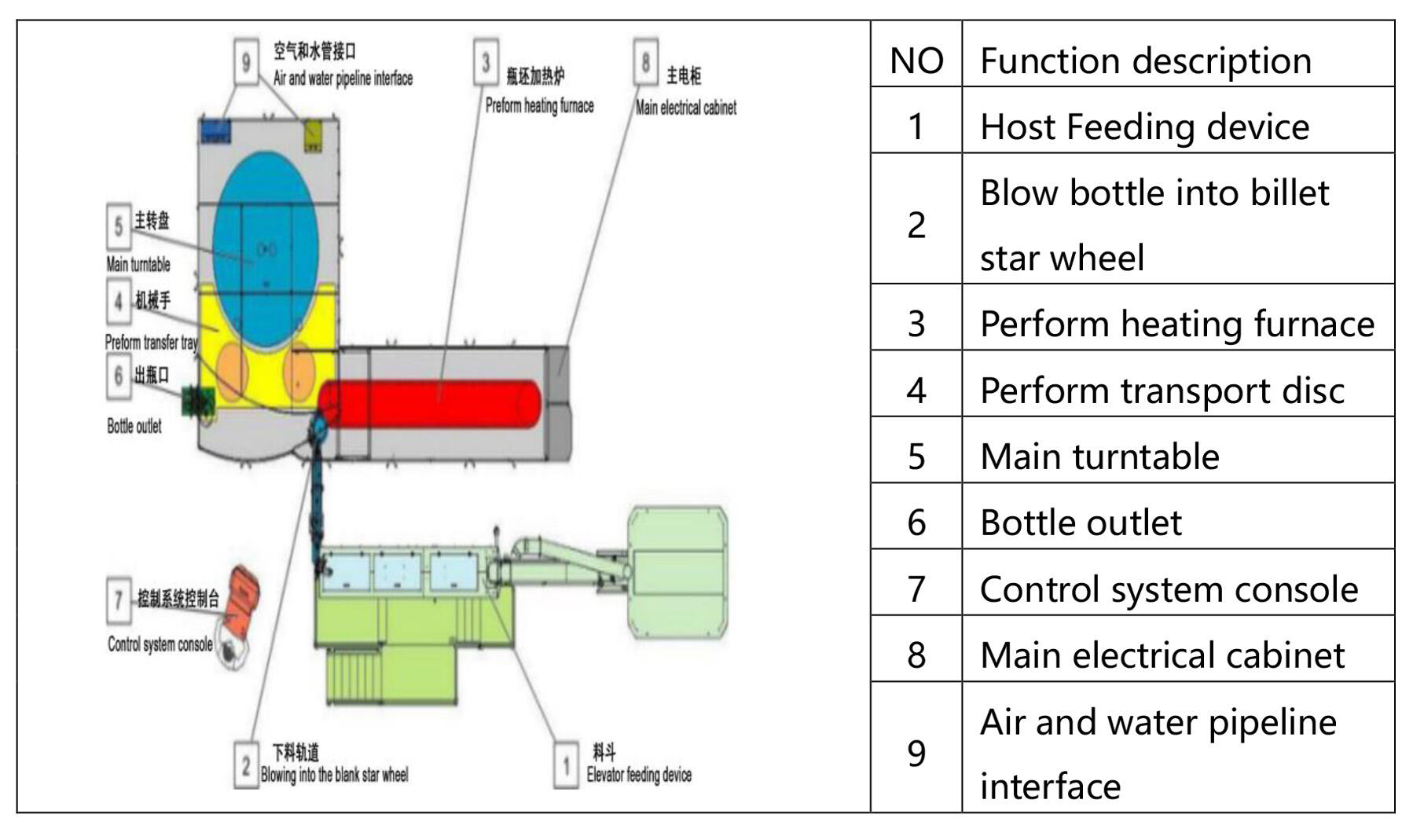

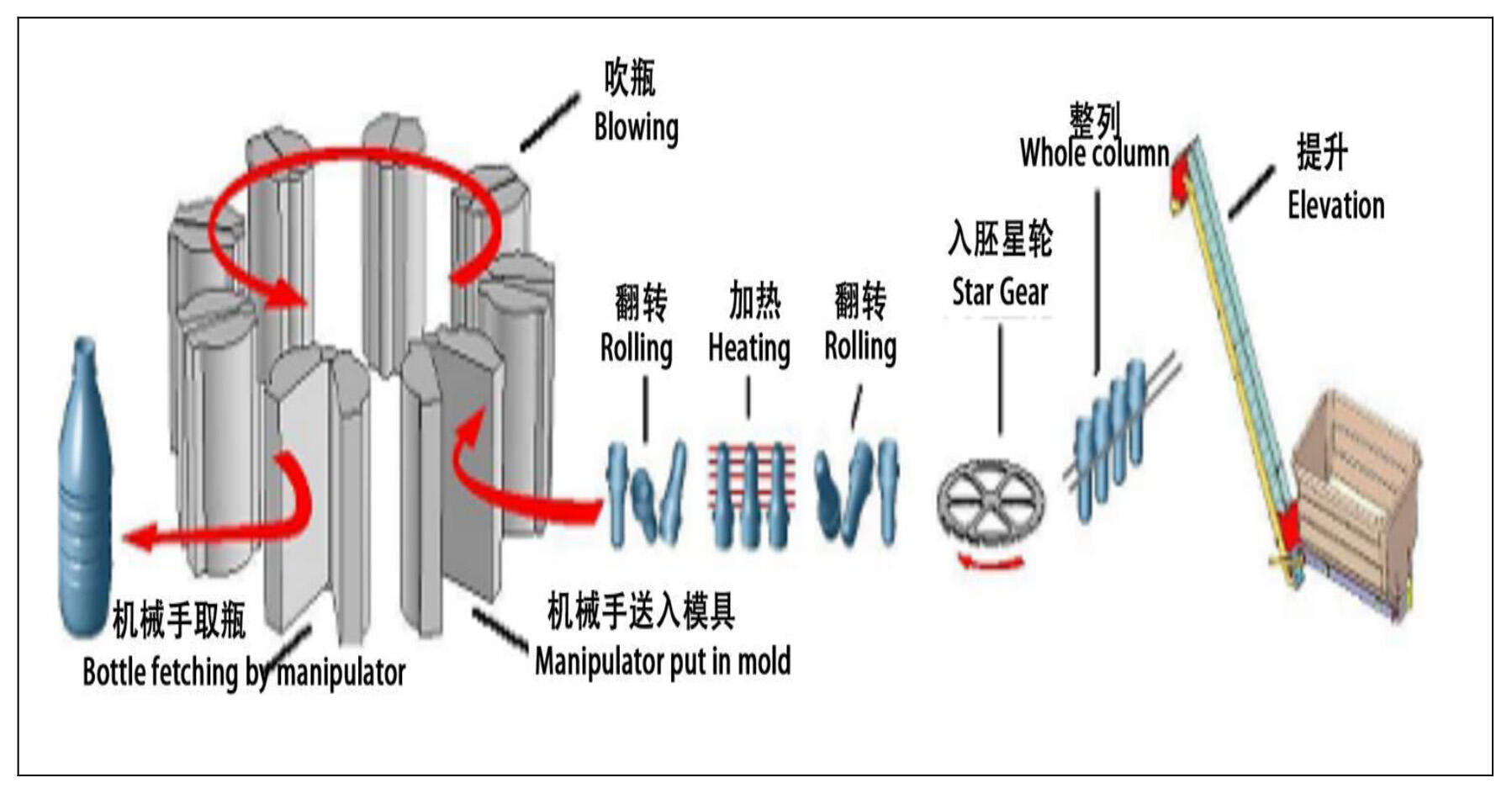

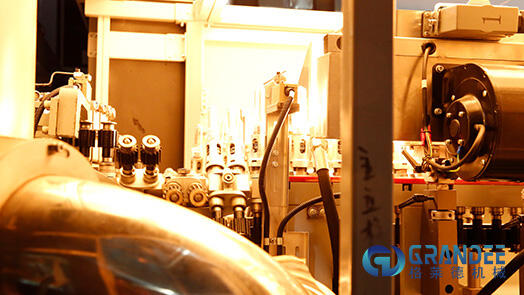

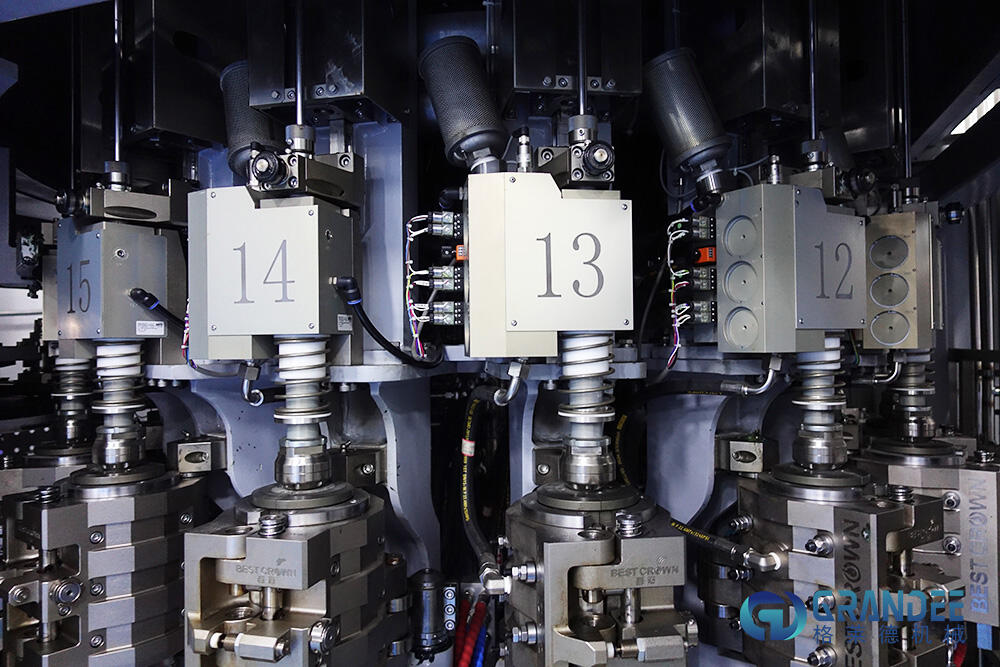

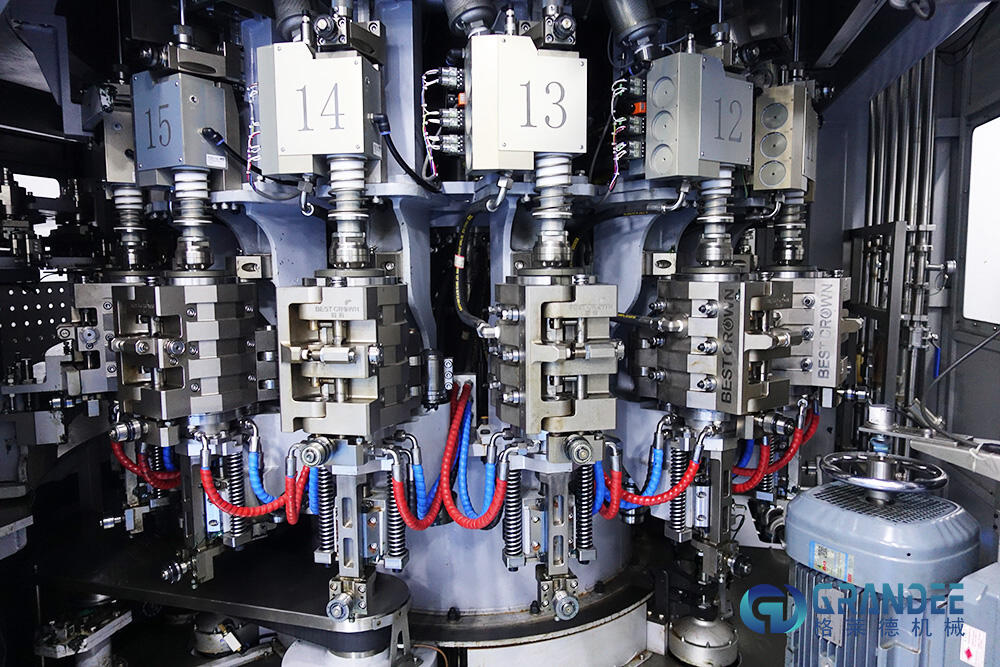

3. The appearance of the bottle blowing machine is shown in the figure The automatic rotary blowing machine is a high-speed two-step blowing machine successfully developed by our company to absorb the most advanced bottle making technology in the world today. The machine is mainly composed of automatic feeding device hopper, lifting mechanism, whole mechanism feeding track, heating furnace, main blowing machine, electrical control system and pneumatic control system

|

NO

|

Model

|

Capacity

|

Bottle size

|

|

1

|

8-24-8

|

12000BPH

|

500ml

|

|

2

|

8-32-8

|

15000BPH

|

500ml

|

|

3

|

8-40-10

|

16000BPH

|

500ml

|

|

4

|

12-42-10

|

18000BPH

|

500ml

|

|

5

|

16-40-15

|

24000BPH

|

500ml

|

|

6

|

20-60-18

|

36000BPH

|

500ml

|

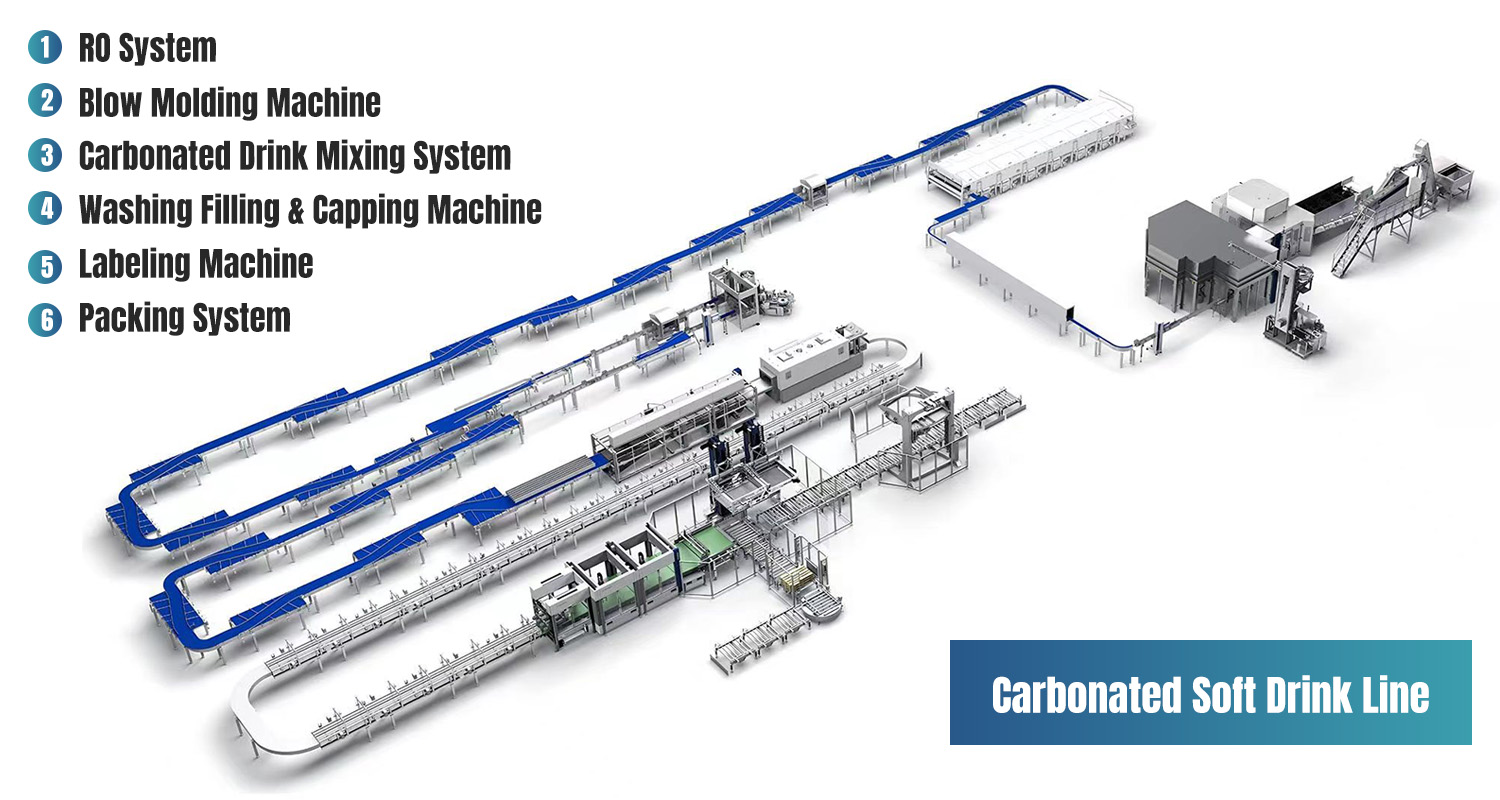

Working Process Flow Diagram

|

Heads

|

|

Filling machine: 24, capping: 8

|

|

10Capacity

|

|

12000BPH 600ml bottle

|

|

Applicable bottle type

|

|

PET bottle

|

|

Applicable bottle type

|

Bottle diameter range

|

D=50~97mm

|

|

|

Bottle height range

|

H=150~310mm

|

|

Compressed air consumption

|

|

0.8m3/min 0.7MPa/h

|

|

Cooling water consumption

|

|

3000L/h

|

|

Cooling water temperature

|

|

1-5℃

|

|

Working voltage

|

|

380V,50HZ

|

|

Control voltage DC

|

|

24V

|

|

Cap torque

|

|

0.6~2.8Nm Adjustable

|

|

Power

|

|

4.0KW

|

|

Dimension L*W*H

|

|

2450x3100x3100mm

Subject to the final drawing

|

|

Weight

|

|

About 12T

|

1. Preform feed-in and unscrambler

It adopts the matured worldwide-standardized way of preform feed-in and unscrambling, in which preforms go through preform elevator and are transmitted to preform unscrambler. Inside the preform unscrambler, preforms are automatically sorted and delivered by two inclined revolving cylinders with same speed, and the remaining ones will be picked by star wheel and sent back to preform hopper. The whole process of preform unscrambling is fully automatic and has high efficiency without preform scratches

Introduction to the blowing machine The core parts, such as the sealing cylinder of the bottle blowing valve island, are all imported and customized by SEITZ. Blow bottle high pressure gas recovery is applied to low pressure gas needs. The inverted heating furnace structure saves energy by 15%. Bottle blowing has pressure detection and bad bottle rejection functions. The system running status can be monitored remotely. Using forged high-strength mold frames, the equipment operates efficiently and stably. The equipment's running track cam is patented, with low vibration, low noise, and stable and reliable operation

Automatic blow molding machine mold The mold is an important factor affecting the PET bottle blow molding process, and the shape of the mold will reduce or increase the difficulty of process adjustment. For example, the reinforcement, the arc of the transition zone and the heat dissipation condition at the bottom have an impact on the process adjustment and directly affect the quality of the bottle, so we recommend that customers pay attention to the novel and unique product packaging and beautiful at the same time, take into account whether the selected bottle type can meet the requirements of use, it is best to be reviewed by our professional designers. When the mold is customized, it is mainly necessary to clarify the material and installation size. Make product capacity height requirements

Advantages of Filling and Capping Machine

1) The rotating disk is made of stainless steel ANSI304 2) Large plane bearing, smooth and reliable operation 3) Filling adopts gravity filling method. The special design of the filling valve port can effectively avoid dripping. At the same time, the special flow channel design of the filling valve can keep the filling liquid column small and stable 4) Ring type liquid cylinder is adopted, and the liquid level is controlled by continuous sensor and flow regulating valve 5) The filling valve is equipped with a cleaning cup, which can perform thorough CIP cycle cleaning of the filling valve 6) Using magnetic constant torque capping head, capping effect is stable and reliable 7) A set of photoelectric switches are installed on the cap-drop guide rail. When there is no cap on the cap-drop guide rail, the machine will automatically stop running, which can effectively avoid the appearance of no bottles cap 8) The bottle inlet detection switch of the capping machine is provided, and the lock cylinder of the cap connecting with the cap guide rail and the cap plate interlock controls the discharge of the cap, ensuring that the cap is stopped when there is no bottle and reducing the loss of the cap

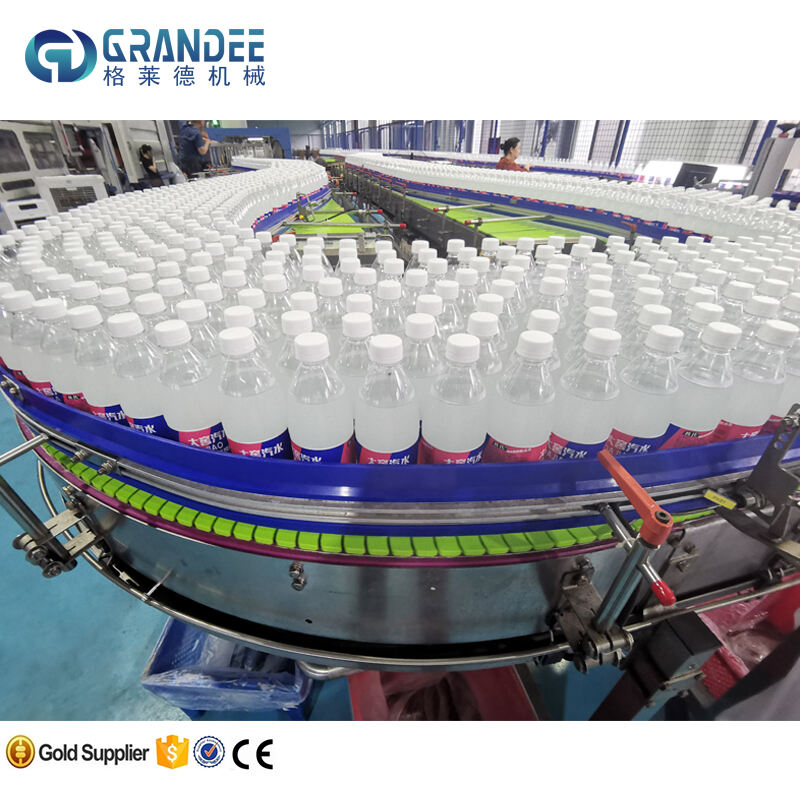

Lubrication System for Conveyor

The spray conveyor belt lubricant, suitable for food, water, beverage, beer, condiments and other industries packaging conveyor belt chain plate lubrication

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

GRANDEE MACHINE

8000-10000bph Combiblock aseptic pasteurized milk blowing filling device is capping yogurt processing bottling line – the solution is best for dairy processing and bottling requirements

Made with precision engineering and advanced technology to make sure performance is effectiveness that optimal. It features a blowing is combined filling, and procedure is capping guarantees a production is streamlined and faster production costs

Made for present in the creation of milk, yogurt, and flavored beverages. It really a remedy is dairy that ideal flowers want an extremely efficient and manufacturing system is dependable. The product shows that your dairy food are managed hygienically and filled to requirements are exacting filling to capping

Fashioned with a pasteurization is high-quality that guarantees your dairy food are safe for consumption. The product was made to heat the milk to a temperature of 72°C for 15 moments before cooling it to the filling temperature

Very efficient and direct to make use of, this bottling line may be created for simple maintenance, reducing downtime and efficiency is increasing. The system comprises elements are a few can typically be disassembled for cleaning and improved hygiene

The equipment's stuffing valves are handled separately by electronic sensors that vow accurate and fill is consistent. In addition possesses an capping is automated, making sure every container is filled to your volume that is correct and is completely sealed

Is sold with a Human-Machine Interface (HMI) that creates operating the merchandise simple and intuitive. The display screen shows statements that are factual the product's performance, including its production price and product usage, providing operators with real-time information they can used to optimize this product's performance

Decide to try our GRANDEE MACHINE 8000-10000bph Combiblock aseptic pasteurized milk blowing device that filling capping yogurt processing bottling line today and have the difference

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM