GRANDEE MACHINE

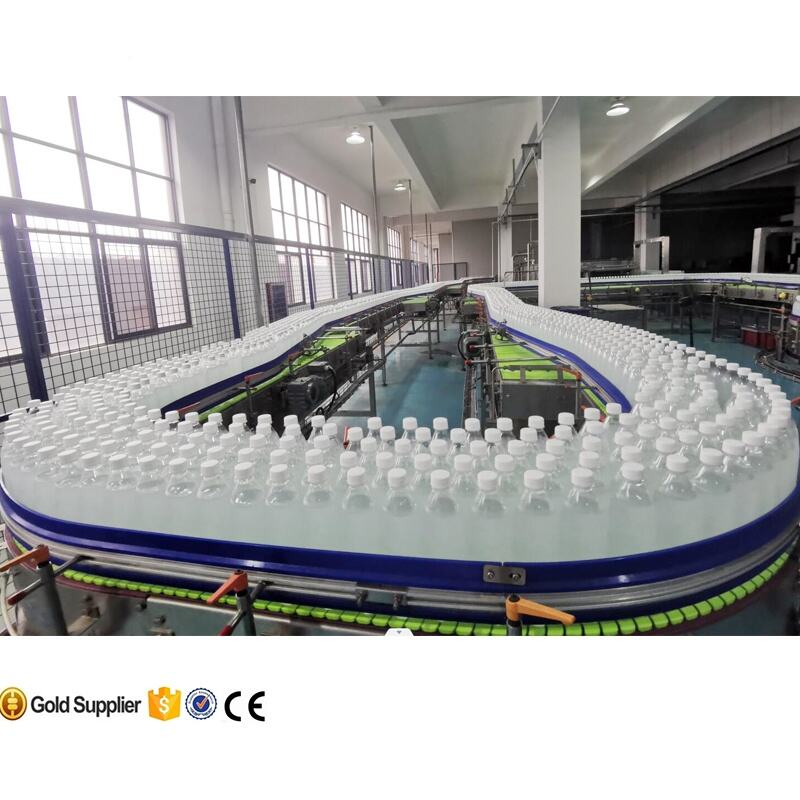

Presenting the 600 900 Bph 5 Gallon bottle Mineral Water Pure Water Filling Machine Bottling line mineral water factory, the latest innovation in mineral water factory technology.

This unique device is specifically designed to fill 5-gallon containers with pure, top-notch mineral water. This product will revolutionize the way your factory produces and bottles mineral water with a manufacturing convenience of 600-900 containers each hour. Crafted from the latest technology and highest-quality materials, the GRANDEE MACHINE is particularly built to run with maximum effectiveness and rate, making sure your factory can create the purest and most refreshing mineral water feasible.

The unit comes with an array of advanced functions rendering it easy to run and maintain. These GRANDEE MACHINE generally include a control this is user-friendly, allowing anyone to adjust the settings to fit your manufacturing requirements, and an array of security features that assure the gear is safe and secure on a regular basis. The container filling procedure additionally simple and easy, as a consequence of the intuitive design associated because of the device. Merely spot the bottle this is empty the conveyor gear, along with the device will immediately fill it with pure mineral water until it is complete.

The apparatus is accurate and exact, making sure each container is filled to your precise degree that exact same. The GRANDEE MACHINE 600-900 Bph 5 Gallon container Mineral Water Pure Water Filling Device Bottling line normally versatile, helping you to effortlessly switch between various kinds containers and fill these with a number of various fluids.

This revolutionary product is as much whilst the duty whether you are creating pure mineral water, purified standard water, or any other forms of beverages. If you are buying a top-notch, reliable, and bottling this is affordable for the mineral water factory, search no further as compared to GRANDEE MACHINE 600-900 Bph 5 Gallon container Mineral Water Pure Water Filling Device Bottling line. This revolutionary product this is amazing assistance are taking your manufacturing to another degree, while making sure your customers may have usage of the freshest and purest mineral water feasible

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

5 Gallon Mineral Pure Water Filling Production Machine

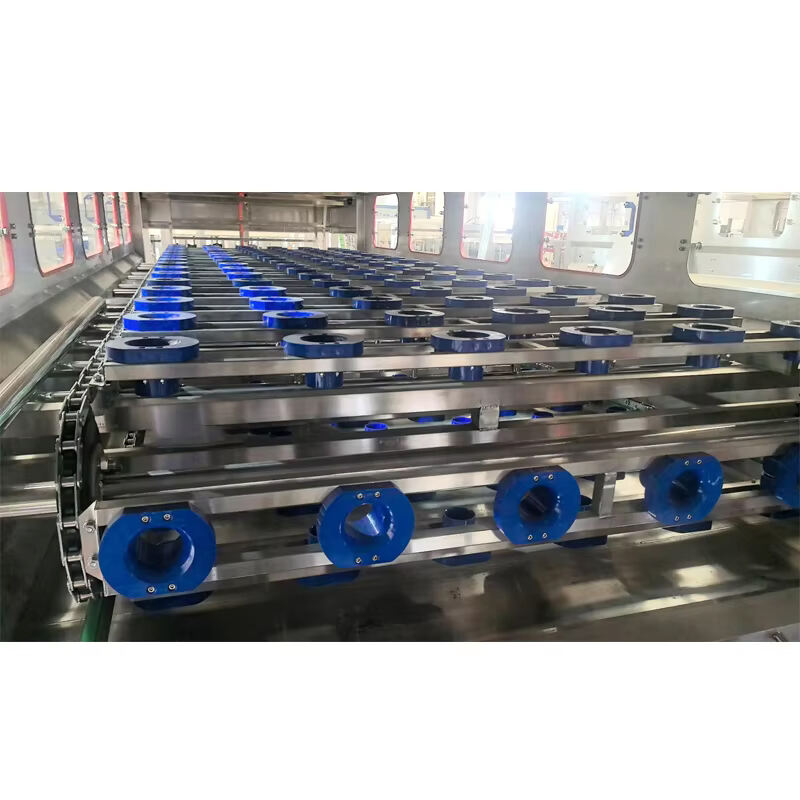

The 5 gallon water filling line specially for 3-5 gallons barreled drinking water, with type QGF-150, QGF-200, QGF-300, QGF-450, QGF-600, QGF-900, QGF-1200. It integrated bottle washing, filling and capping into one unit, in order to achieve the purpose of washing and sterilizing, The washing machine uses multi-washing liquid spray and disinfectant spray, the disinfectant can be used circularly, The capping machine can be cap barrel automatically, The line equips with water spraying device in order to ensure those caps sterile and clean, it also can automatically carry out barrel, washing, sterilizing, filling, capping, counting and products discharging, with complete function, modern design and high degree of automation, It is a new kind of barreled water auto producing line, which integrates mechanism, electricity and pneumatics technologies together

Washing part

1. In order to achieve the purpose of washing and sterilizing, bottle washer adopts multiple liquid injections washing and disinfectant spray, and washing solution can be used circularly

2. There are five or seven flushing process: First, second steps are disinfectant, the third step: drip dry, four step: recycling water inside and outside rinsing, five step: pure water and drip dry

Water tanks

This filling machine has water tanks with thick strong and good quality SUS304, one is disinfectant tank, two is pure water tank

Water pumps

This filling machine has three good quality water pumps

Filling sealing part

This filling machine and sealing machine working with automatic cylinder controlled, cap holding and cap hopper, use gravity filling type, full bottle filling process

Automatic cap unscrambler

Automatic cap unscrambler works very smooth, with function of alarm for lack of caps

|

Model

|

|

QGF-200

|

QGF-300

|

|

|

QGF-900

|

|

|

|

|

|

|

|

|

Capacity(500ml/BPH)

|

150

|

200

|

300

|

450

|

600

|

900

|

1200

|

|

|

|

|

|

|

|

Suitable bottle shape and size

|

|

|

|

|

|

|

|

|

Compressed air pressure

|

|

|

|

|

|

|

|

|

Bottle washing medium

|

|

|

|

|

|

|

|

|

Washing pressure

|

|

|

|

|

|

|

|

|

Main motor

|

1.5

|

2.2

|

2.2

|

2.2

|

4.5

|

5.5

|

7.5

|

|

|

|

|

|

|

|

Dimension(mm)

|

2900*1000*1800

|

3200*1200*2300

|

3900*1200*2300

|

5000*1500*2300

|

6200*18*2300

|

7970*1800*2700

|

10780*2000*2700

|

|

|

|

|

|

|

|

Weight(KG)

|

500

|

1500

|

3000

|

3500

|

4500

|

5500

|

7500

|

|

|

|

|

|

|

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

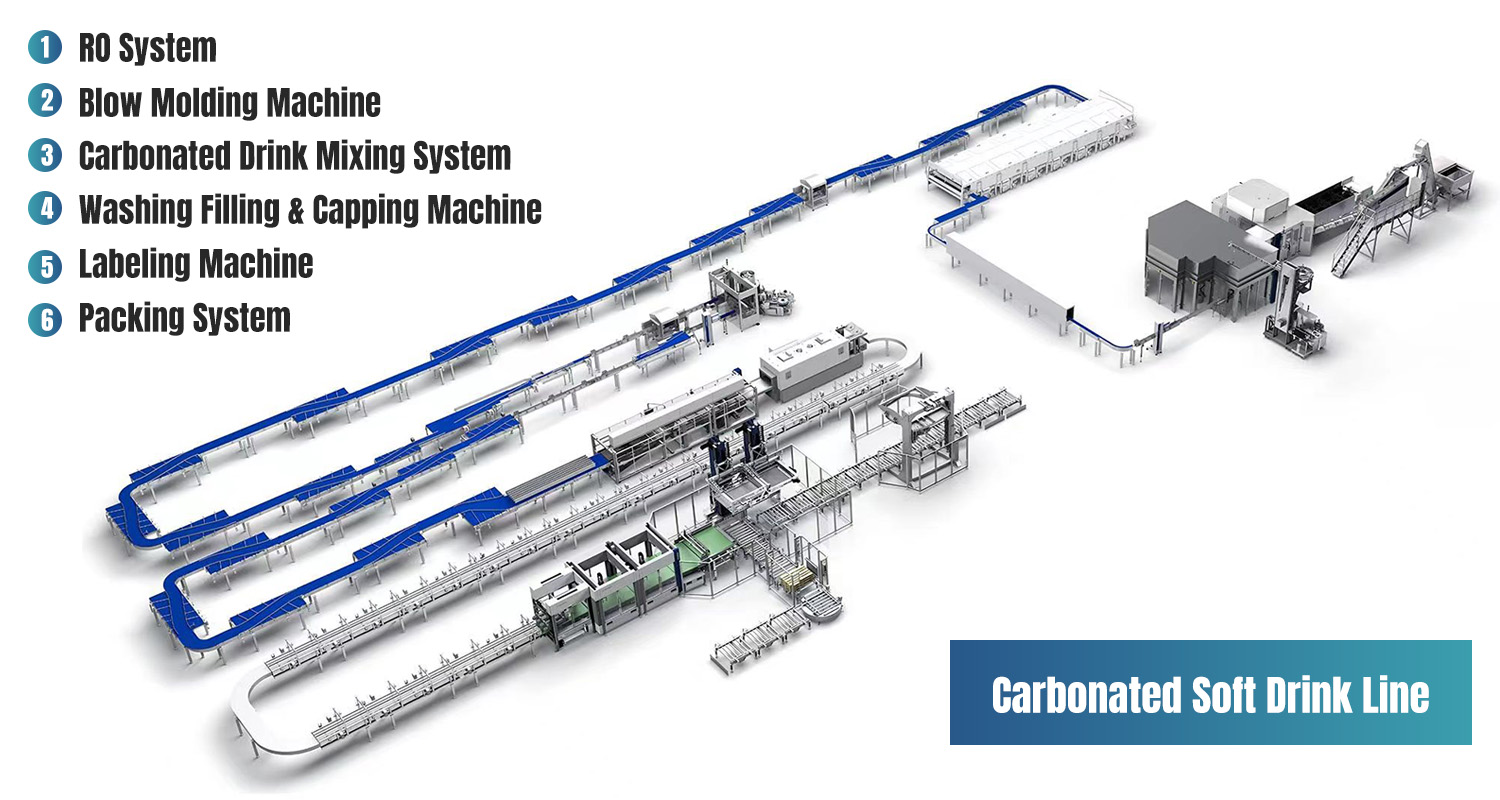

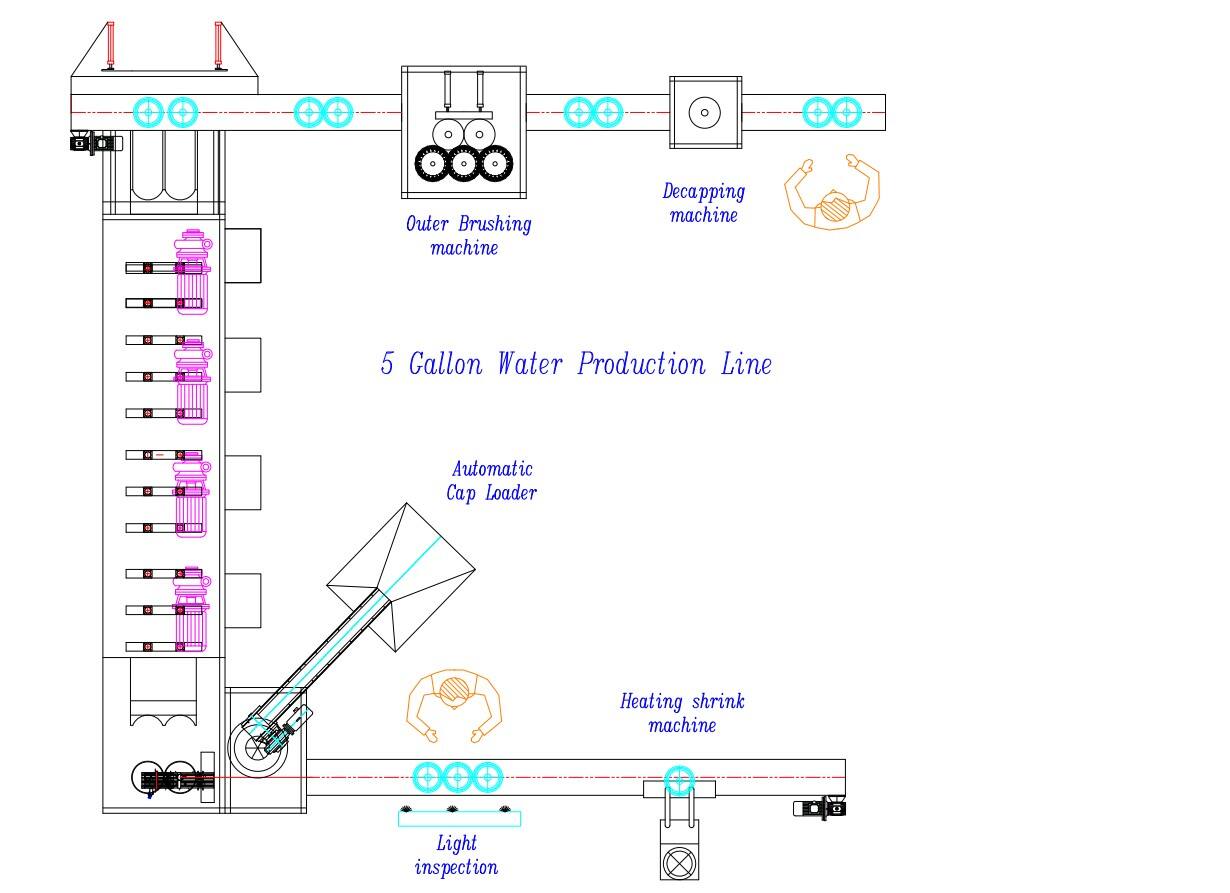

1. Decapping machine 2. bottle interior and exterior washing machine 3.5 gallon washing filling capping machine 4. Sleeve shrink labeling machine 5. Bag packing machine 6. Palletizer

One stage or Second stage R. O. Water treatment system

Raw Water Tank→ Raw Water Pump→ Quartz Sand Filter→Activated Carbon Filter→ 5 Micron Filter→ 1 Micron Filter→High Pressure Pump→Primary Reverse Osmosis Device→Intermediate Water Tank→ Booster Pump→ (Secondary High Pressure Pump→Secondary Reverse Osmosis Device) → Ozone Mixer→Pure Water Pump→ Pure Water Tank→ External Supply Pump→ Titanium Tube Filter→ External Supply→ To Filling Machine

Automatic OPP BOPP hot melt Glue labeling machine

Automatic BOPP labeling machine is widely suitable for different material of containers and labels. The cost of each label is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is one of the most economical models to make mass production and integrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, like changing the label is only needed to change the PLC program, the products concept that the equipment is used for users and considered for users is embodied in everywhere.

Automatic PVC PE Sleeve Shrink Labeling Machine

This fully automatic sleeve labeling machine is suitable for various kinds of bottles, like round bottles, square bottles, oval bottles, etc. This machine can automatically feed and cut film, and it can sleeve labels precisely, greatly saving labor and improving work efficiency. The machine can be widely used for beverage bottles, cosmetic bottles, shampoo bottles, etc.

Operating Principle Of Packaging Machine

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10, 000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line, can filling and sealing line, complete blowing labeling and packaging system

We have laser cutting, CNC machining centers, and other various processing equipment to provide customers with precise and reliable products. The ERP system provides an important resource integration path for production management and ensures production and delivery cycles

A1: Looking for beverage filling machine in www. Grandeemachine. en. alibaba. com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team, providing good and after-sales service term, professional salesman terms

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee, and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing

For more information, please feel free to contact us to send inquiries!

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM