5 Gallon Mineral Pure Water Filling Production Machine

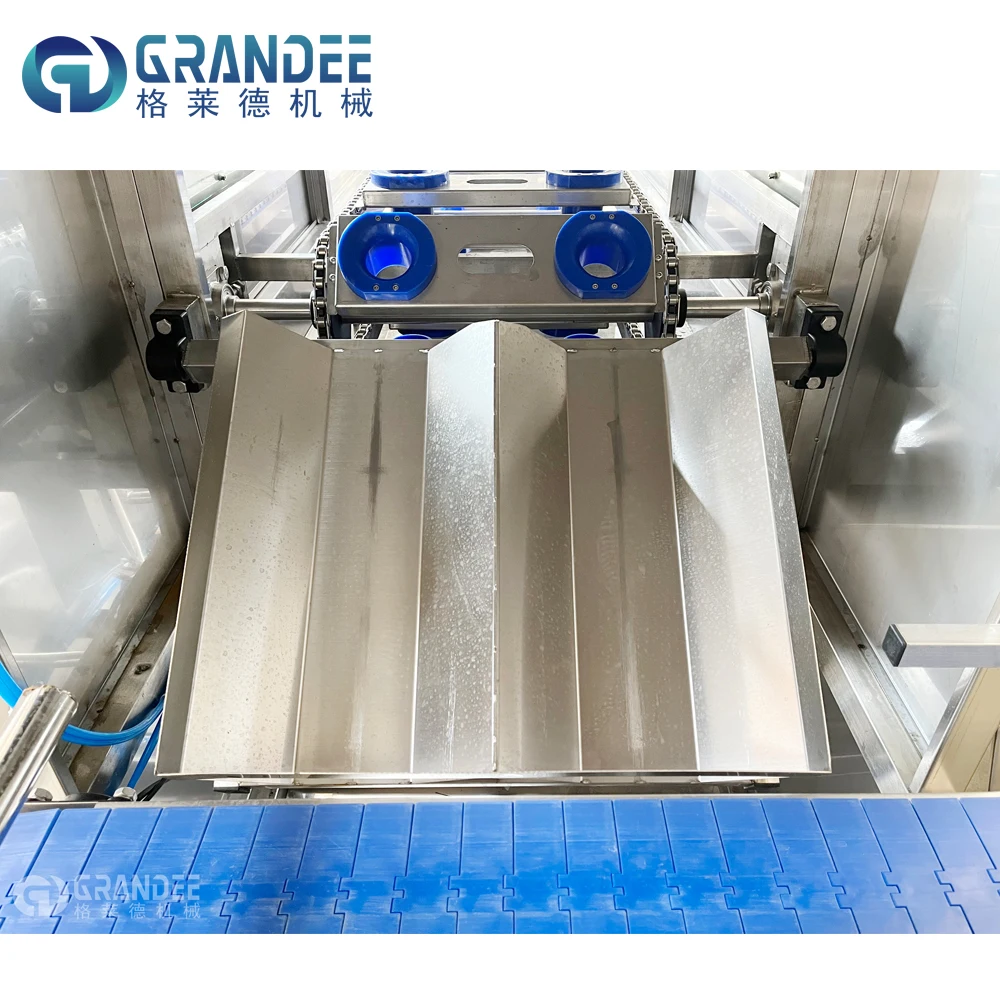

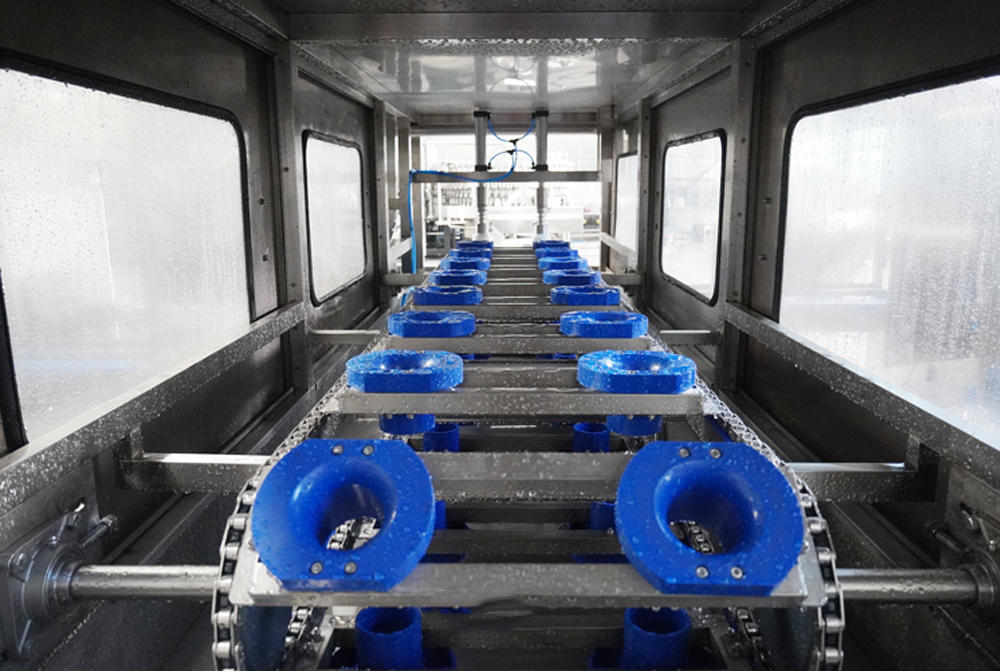

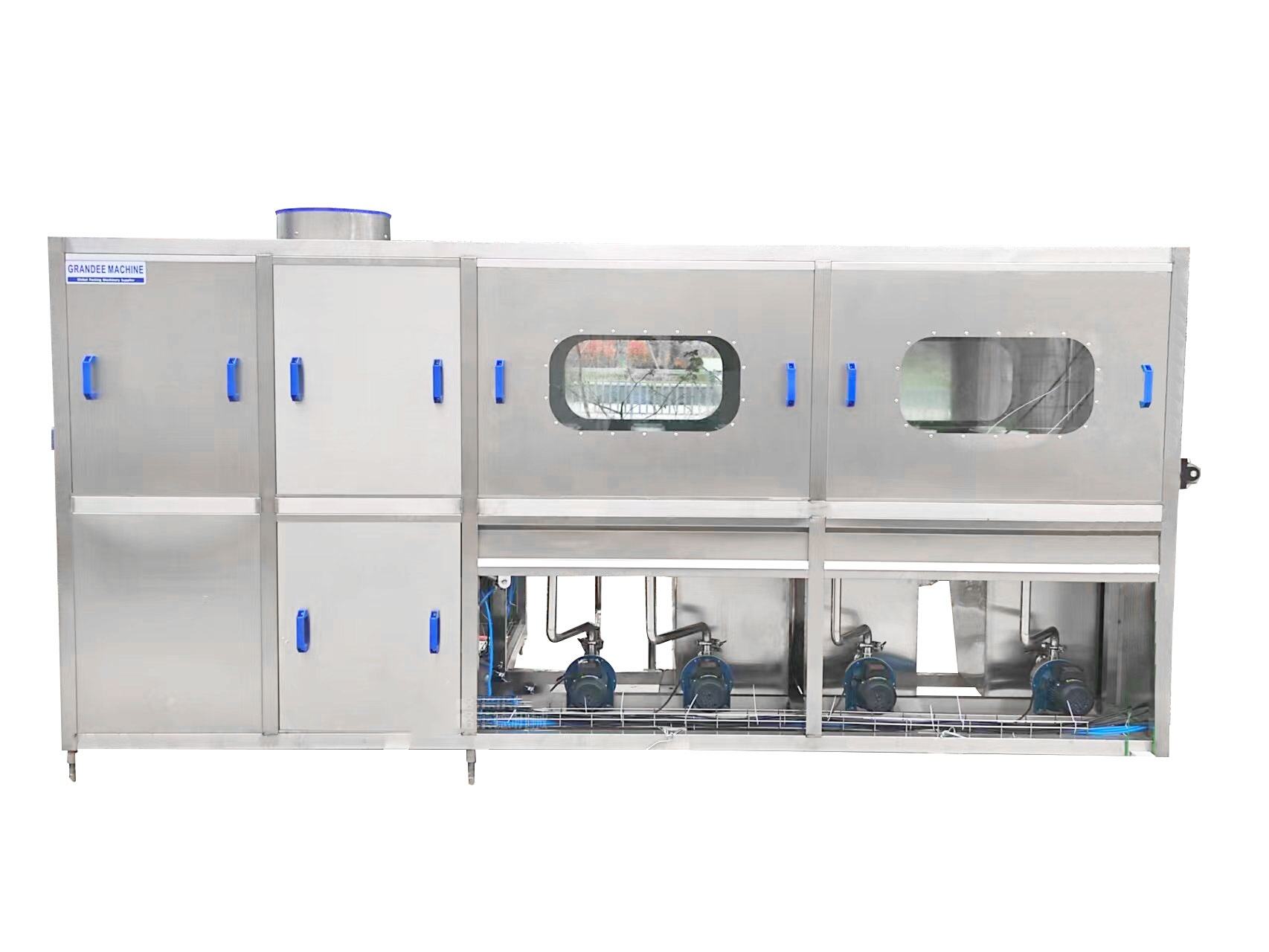

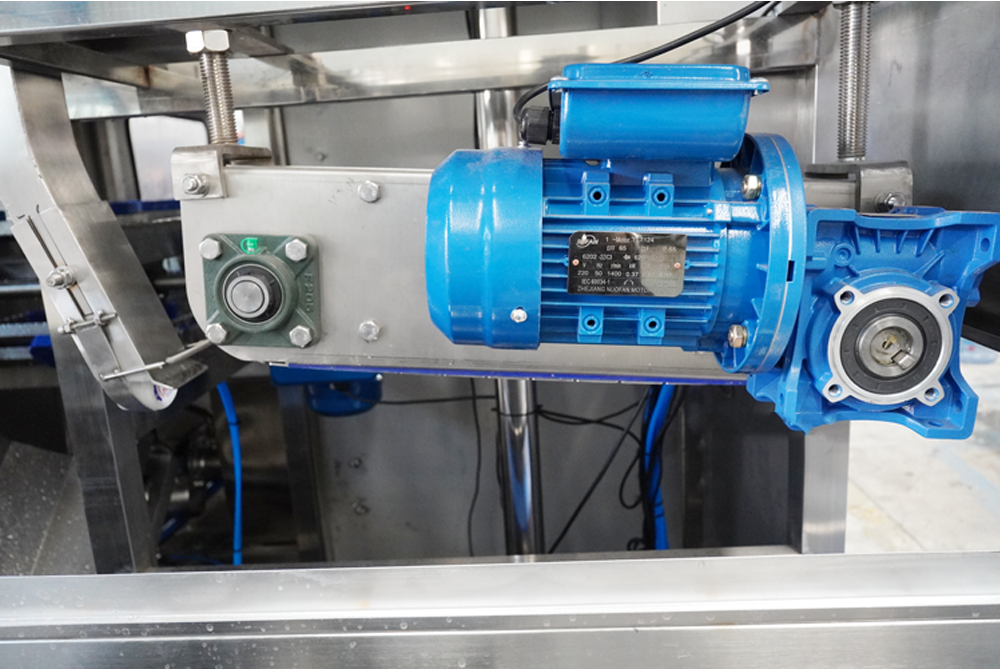

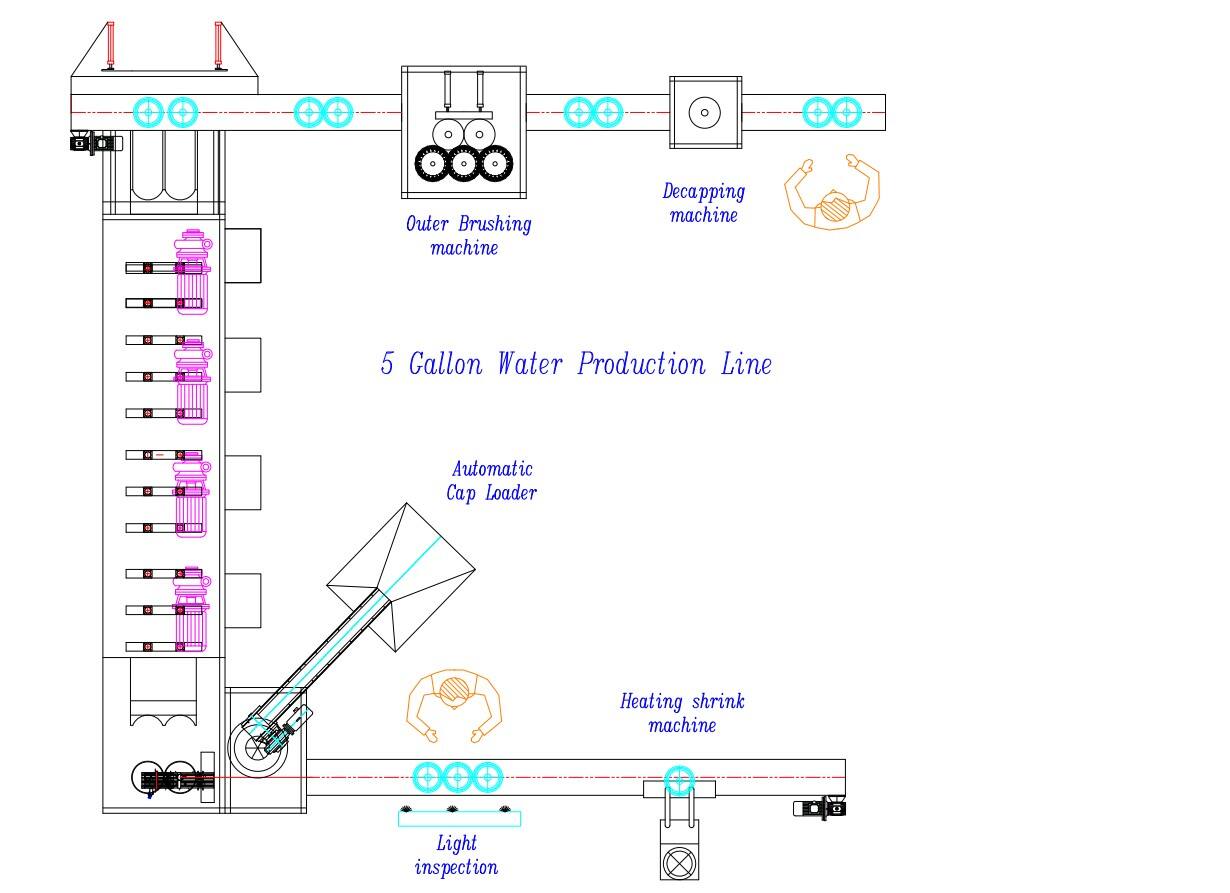

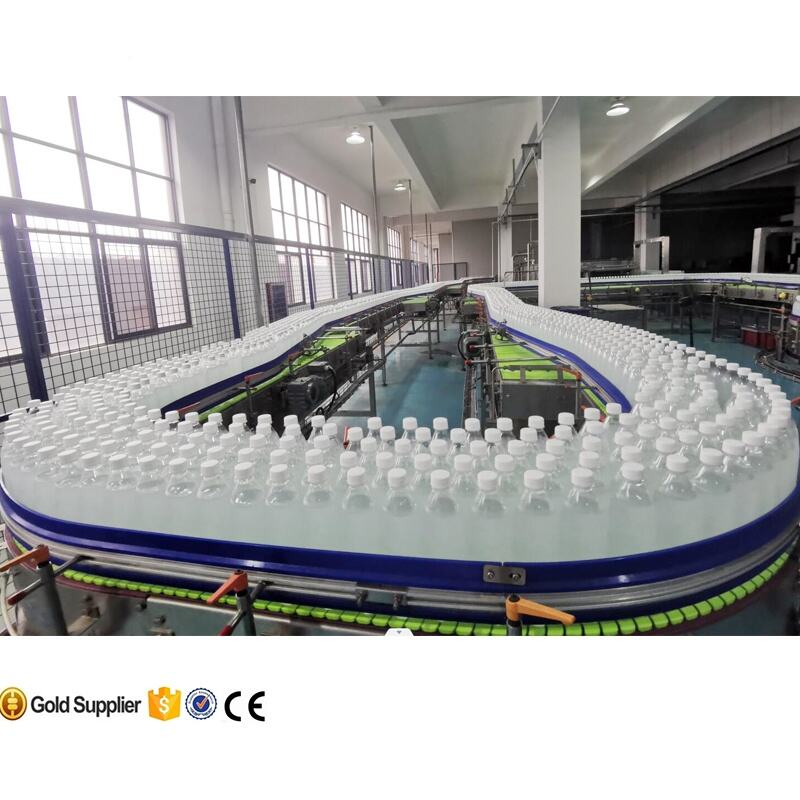

The 5 gallon water filling line specially for 3-5 gallons barreled drinking water, with type QGF-150, QGF-200, QGF-300, QGF-450, QGF-600, QGF-900, QGF-1200. It integrates bottle washing, filling and capping into one unit, in order to achieve the purpose of washing and sterilizing, The washing machine uses multi-washing liquid spray and disinfectant spray, the disinfectant can be used circularly. The capping machine can be cap barrel automatically. The line equips with water spraying device in order to ensure those caps sterile and clean, it also can automatically carry out barrel, washing, sterilizing, filling, capping, counting and products discharging, with complete function, modern design and high degree of automation, It is a new kind of barreled water auto producing line, which integrates mechanism, electricity and pneumatics technologies together

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM