Production Capacity:

5000 bottles/hour – 48000 bottles/hour

Applicable Products:

Dairy, water, fruit and vegetable drinks (carbonated and non-carbonated), alcohol, edible oil, soy sauce, vinegar and other liquid condiments and viscous materials

I 、Equipment selection principle:

1) The product has strong adaptability, complete functions, high degree of automation, maturity and stability, low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, good reputation.

4) Aim at the domestic advanced level as far as possible, giving priority to the use of mature and advanced equipment to achieve the processing of its key processes.

Suitable Container:

All kinds of glass containers

Filling Method:

Mechanical valve filling, electronic valve filling, flow control type, liquid level control type, weighing type, etc

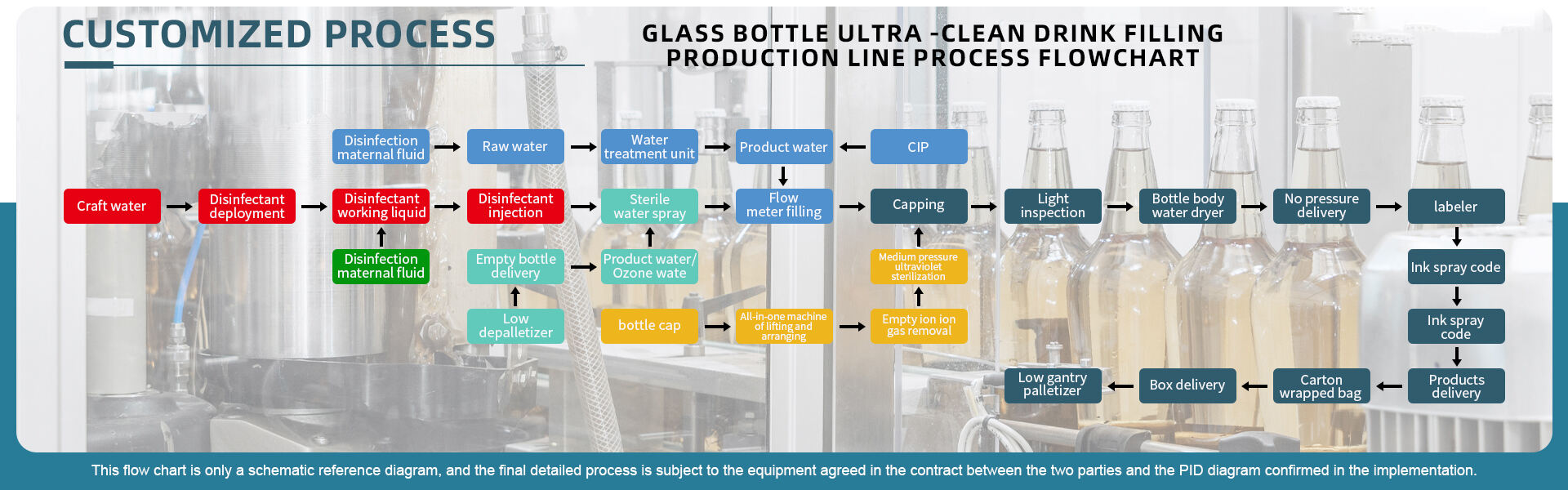

III 、Our customize PID

IV 、 Whole plant project

Characteristic:

This series of models run smoothly, accurate filling, and suitable for cold and hot filling.

The design of the machine is reasonable, the structure is compact, and the safety protective cover is added. The CQC Quality Certification of the China Quality Certification Center is passed.

Reasonable design and compact structure. All contact with the material is made of stainless steel 316.

The degree of automation is high. It can be automatically completed and automatically complete the processes such as the feeding bottle, filling, and bottle outlet. The operating speed uses the frequency conversion speed. It is equipped with a safety protection device such as the feeding bottle, inverted bottle, outlet blocking and automatic stop. The whole machine is safe and reliable.

The series of products with a series of products can meet all kinds of different production capacity and filling capacity. There must be one that can meet your needs.

Glass bottle carbonated beverage filling and packaging production line

Equipment Composition:

Including unloading machine, bottle washing machine, bottle preheating machine, filling and capping machine, capping machine, loading and unloading cage machine, sterilizer, bottle printer, packing machine, solid bottle delivery system, box delivery system, electrical control system and so on, including a complete set of filling and packaging production line.

Optional Equipment:

Box unloading stacker, box stacking machine, empty bottle electronic inspection machine, full bottle testing machine, full box testing, etc.

Glass bottles Other products:

Concentrated or sauce products: such as tomato sauce, jam, fruit and vegetable mud, chili sauce, honey, alfalfa, corn cricket, peanut butter, sand, etc., are also suitable for granular liquids, such as grain orange, bird's nest, aloe, rice wine, etc. Essence It is suitable for a variety of packaging containers such as tin cans, glass bottles, and hard plastic containers.

High -precision filling non-carbonated, low -viscosity, and high -hygiene standards: such as drinking concentrated fruit juice, tomato salad, chili sauce, soy sauce, vinegar, honey, edible oil, oyster sauce, chicken sauce, etc.