Production Capacity:

10000 bottles/hour -72000 bottles/hour(500 ml); for the bottle types of 150ml-2000ml

Applicable Products:

Mainly used for packaging various types of PET bottles of carbonated beverages

I 、Equipment selection principle:

1) The product has strong adaptability, complete functions, high degree of automation, maturity and stability, low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, good reputation.

4) Aim at the domestic advanced level as far as possible, giving priority to the use of mature and advanced equipment to achieve the processing of its key processes.

III 、Our customize PID

IV 、 Whole plant project

IVV、Feature

PET bottle containing steam: carbonates, beer and other beverages containing steam, carbon dioxide dissolved content 2.5-4.2 times CSD;

Gas-filled and non-gas-filled beverage filling valves are compatible.

Achieve segmented exhaust, fast and slow exhaust, inhibit foam, achieve 15-18 degrees Celsius filling, saving energy.

Plant t model selection

High-precision sugar-water mixing system: The rationing system is composed of water pump, water mass flowmeter, syrup pump, syrup mass flowmeter, syrup regulating valve and industrial computer. It can be adjusted online, and the mixing accuracy is extremely high, and the sugar degree deviation of the finished product reaches the set value of ±0.05, or even lower.

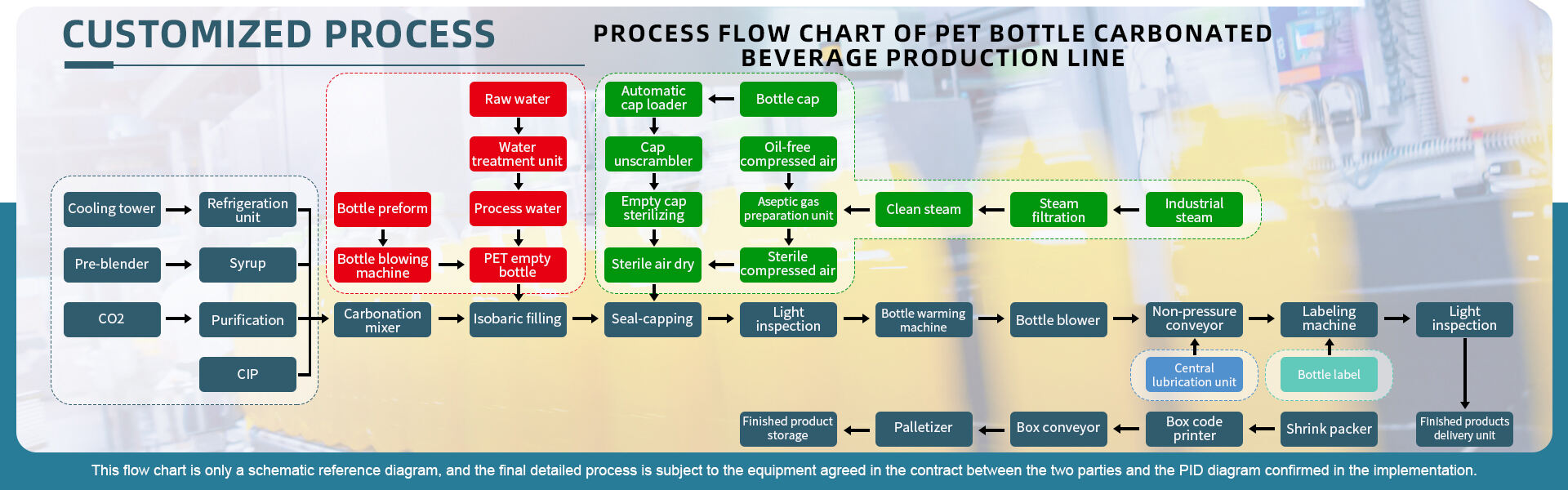

PET bottle carbonated beverage filling and packaging production line

Can use advanced electronic isobaric filling valve, suitable for a variety of materials, high filling temperature, high filling level accuracy, less carbon dioxide consumption.

Equipment composition:Including automatic bottle blowing machine, wind conveying line, bottle filling screw cap three line, cap conveying machine, mixing machine, warm bottle machine, OPP labeling machine, inkjet machine, shrink film packaging machine, palletizer, winding machine, solid bottle conveying system, box conveying system, electrical control system, etc.

Optional equipment: automatic bottle sorting machine or manual bottle sorting system, bottle warehouse, automatic bottle unloading machine, label machine, carton packaging machine, etc.