Production Capacity:

5000 bottles/hour – 48000 bottles/hour

Applicable Products:

Water, fruit and vegetable drinks (carbonated and non-carbonated), beer, and other liquid foods

I 、Equipment selection principle:

1) The product has strong adaptability, complete functions, high degree of automation, maturity and stability, low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, good reputation.

4) Aim at the domestic advanced level as far as possible, giving priority to the use of mature and advanced equipment to achieve the processing of its key processes.

Suitable Container:

Aluminum cans and iron cans of different capacities

Filling Method:

Mechanical valve filling or electronic valve filling

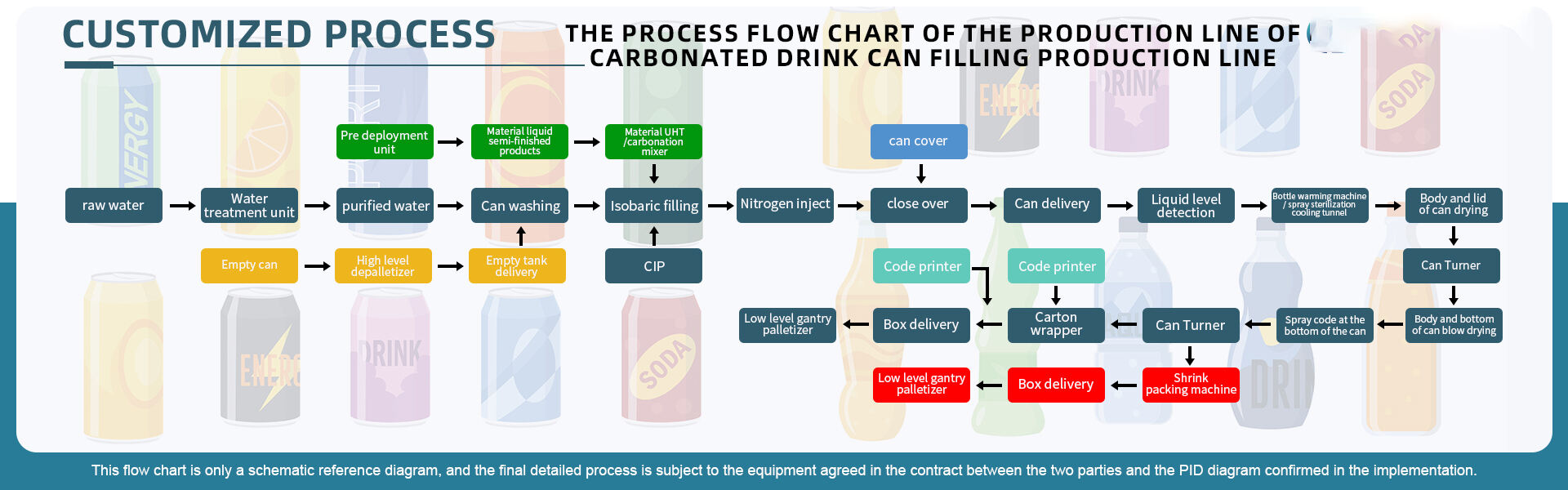

III 、Our customize PID

IV 、 Whole plant project

IVV 、Feature

The machine adopts high precision flow metering electronic filling valve, isobaric filling; The filling valve has the function of carbon dioxide air displacement, and the oxygen increase of the product is very low during filling.

All actions in the filling process: air displacement, carbon dioxide back pressure, wine filling, pressure relief, are automatically controlled by PLC; Filling amount, air displacement time, number of pressure relief stations, etc. can be set on the PLC control interface.

All dynamic seals of the filling valve are made of corrugated pipe or rubber diaphragm, no cleaning dead Angle, to ensure that the filling valve is in a sterile state. Filling valve with automatic CIP cleaning cup.

According to the supply of empty cans in front of the filling machine and the accumulation of solid cans on the conveyor belt behind the filling machine, the filling machine can be automatically controlled.

The rack platform is of hygienic design. Circular cylinder, no cleaning dead Angle. Adopt hygienic valve array.

Electronic filling valve with high precision flow measurement

Automatic operation, all actions can be set on the PLC control interface

It is suitable for filling of soft drinks and beer cans with or without gas

High degree of automation, stable performance, integration of filling and sealing