Capacity Range:

600 bottles/hour -3000 bottles/hour

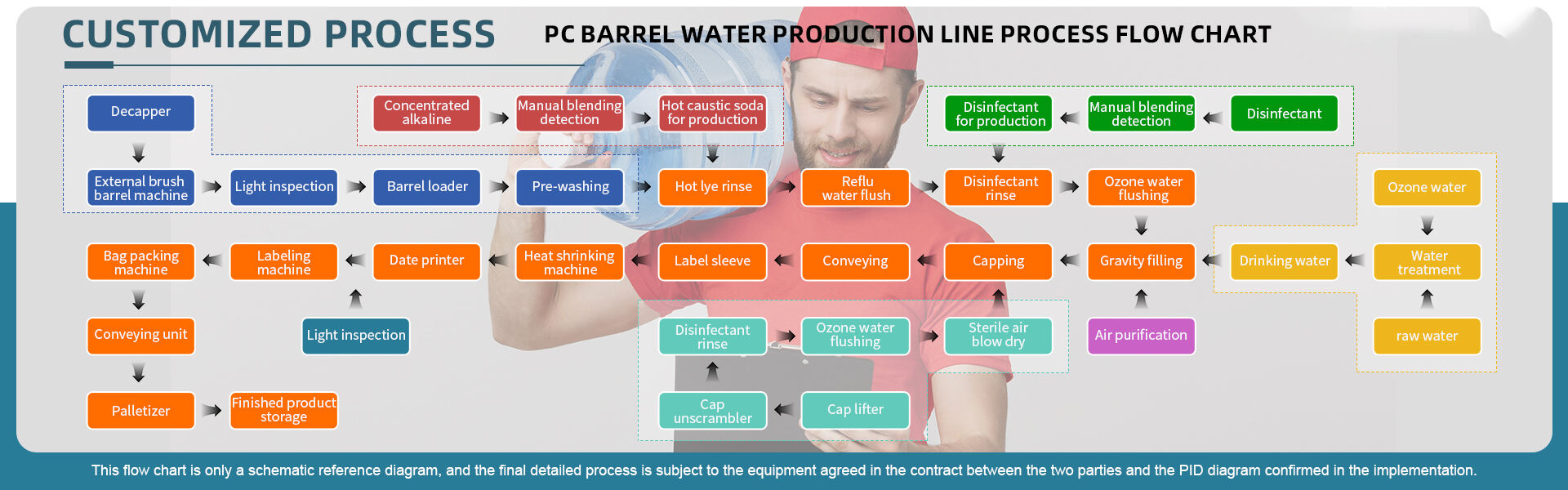

This production line is designed for online production of bottled drinking water. The production line can automatically complete the functions of cutting film, uncapping, cleaning outside the barrel, cleaning inside the barrel (lye, pharmaceutical liquid, sterile water washing, can be customized high-pressure washing), non-contact quantitative filling, online disinfection of bottle caps, cap management, cover, capping, sleeve label shrinkage, coding, bagging, palletizing, conveying, storage and so on. The production line has the features of complete functions, compact structure, novel design, high degree of automation, simple operation, stable and reliable operation, etc. It is a technical drinking water barreling equipment integrating machine, electricity and gas.

The control part of the production line adopts a split electrical control cabinet, which is operated by man-machine interface to achieve the functions of fault point display, automatic control of production detection and operation, and fault alarm function.

III 、Our customize PID

IV 、 Whole plant project

2、Composition of production line

Automatic film cutting machine

Automatic cover pulling machine

Automatic external washing machine

Automatic bucket loading system

Automatic barrel cleaning machine (including lye and liquid cleaning)

Intelligent filling and capping integrated (non-contact quantitative filling)

Automatic cover feeding machine

Online lid, disinfection and cleaning machine

Floor type LED light inspection box

Automatic barrel mouth marking machine

Automatic steam shrink machine

Laser coding machine

Automatic bagging machine

Automatic palletizer

Conveying and control systems

IVV、FillingFeature

Linear filling and capping machine

The equipment adopts frequency conversion filling, LYSF sanitary flow control valve, LYSF sanitary pneumatic diaphragm valve to realize timed quantitative filling, accurate filling quantity and smooth operation. The filling buffer tank balances the output pressure and flow of the filling pump.

For buckets of different heights, there is an active elastic adjustment system, with high inclusiveness;

The principle of chain gland is simple, the continuity of gland is good, and the sealing effect of gland is good;

The cover is continuously sealed with stainless steel chain. The cover is stable and accurate, the chain cover is stable and smooth, the bucket is not down, and the success rate is high.

The structure of the machine is compact and reasonable, which can greatly reduce the area of the purification workshop and save costs.

Rotary filling and capping machine

The filling and capping machine has a rotating structure. It is composed of transmission system, inlet and outlet barrel system, filling system and capping system. After cleaning the barrel, through the conveyor chain to the filling and sealing machine. The barrel is transferred into the filling machine by the intake drum wheel, and after filling to the specified capacity, the barrel is transferred into the sealing conveyor chain by the outgoing drum wheel, and the barrel mouth is sealed by the upper cover and gland.

Filling control: imported photoelectric beam can be used;

Each filling head can adjust the flow rate, the flow rate can be adjusted with the filling speed, and ensure that the filling at constant flow rate, each filling head can ensure that the quantitative filling liquid level is stable, no overflow;