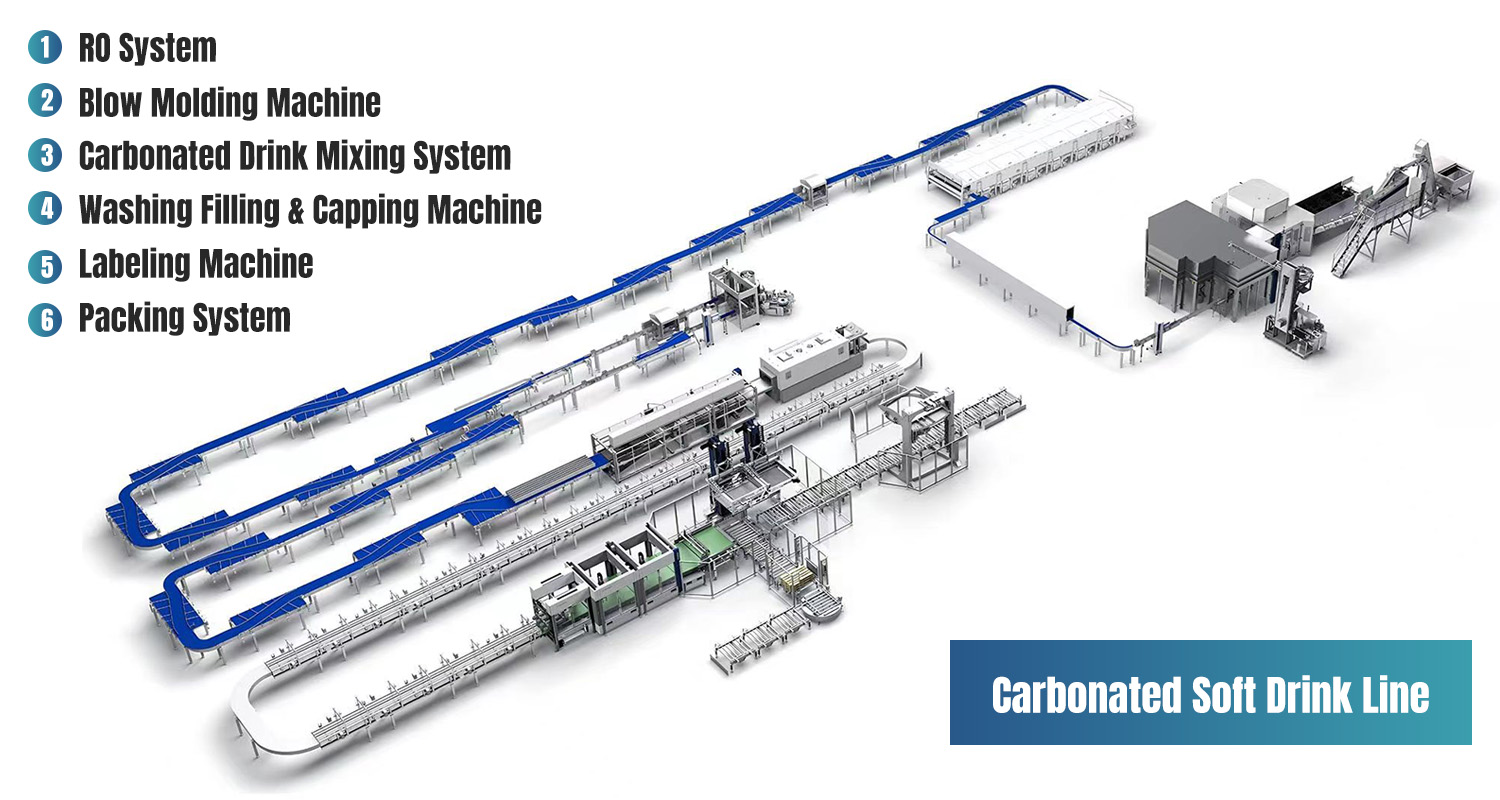

Carbonated Filling Machine DXGF50-50-12

Carbonated drink filling equipment adopts bottle neck holding transmission technology to realize fully automatic bottle rinsing, pulp filling, carbonated filling and cap screwing. It employs single cavity plunger type of fixing filling volume technique. It is equipped with CO2 accuracy pressure control, so that the liquid level is always stable. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation etc

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM