GRANDEE MAHINA tezlikdagi avtomatik hidravlika stol bulblari injektsiya formash plastik ishlab chiqarish mashinisi haqida guruhga taklif etmoqda. Bu innovatsion mashin plastik ishlab chiqarish sanoatida to'g'ri va aniqlik uchun dizaynlangan. Bu mashin sofistike qilingan va bir vaqtning o'zida oson foydalanish orqali, bu uni ikkadalar va boshlang'ichlar uchun ham yaxshi tanlov qiladi.

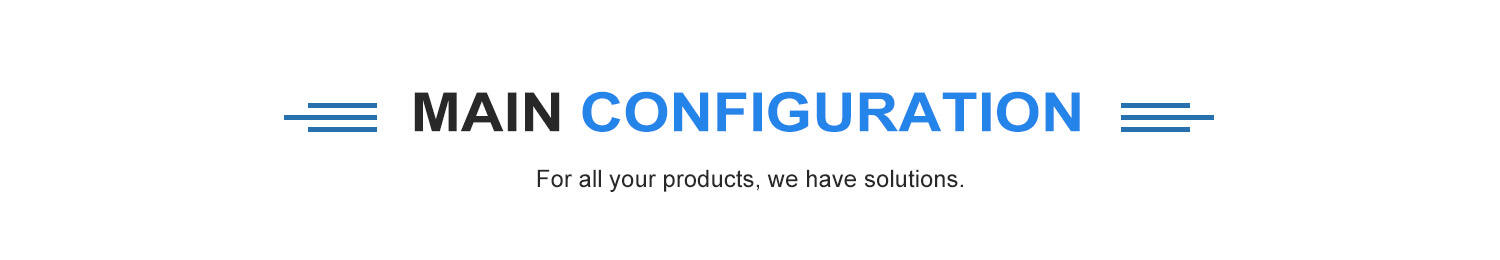

Uchta Tezlikli Avtomatik Hidravlika Dekstop Dripper Bulb Inieksiya Forma Mashini plastik ishlab chiqarish uchun mo'ljallangan va kuchli hidravlika tizimiga ega, bu esa unga yuqori sifatdagi plastik qismlarni ishlab chiqarish imkoniyatini beradi. Uning tezligi boshqa o'xshash mashinalarga nisbatan oson yoqiqlikda yutuqlidir. Bu uni avtomobil, elektronika va uy ishlari kabi turli sanoatlar tomonidan foydalaniladigan plastik qismlarning katta hajmdagi ishlab chiqarish uchun ideal qiladi.

Mashinaning butunlay avtomatik bo'lishi sababli, bu ishlab chiqarish jarayonini tez va efektdor qilish uchun odamning kamida ham kasbiy kirishi talab etiladi. Oddiy inieksiya forma kabi klassik ishlab chiqarish usullariga nisbatan, ushbu mashina ishlab chiqarish vaqti niyatlangan va materialni ishlatib tashlashni kamaytirish uchun eng yaxshi tanlov hisoblanadi.

Osonlik va qarorli bo'lish har qanday ishlab chiqarish jarayonida muhim omillar hisoblanadi, va Uchboq Automatic Hydraulic Desktop Dripper Bulb Injection Molding Machine Plastic Making Machine shu ikkalasini ta'minlash uchun dizaynlangan. U yuqori sifatli materiallardan tuzilgan va uning odobiy asosida mashina ishlashiga mustaqil asos beradi, maksimal ishlab chiqarish natijalarini ta'minlaydi.

Mashina foydalanuvchi uchun qulay, bu esa plastik ishlab chiqarish sohasiga yangi kelsa ham oson ishga tushirishini ta'minlaydi. U aniq va oson tushuniladigan talablarga ega bo'ladi, bu esa foydalanuvchilarga uni osonroq ishlatish imkonini beradi. Mashina kontrolli paneli ishlab chiqarish jarayonini oddiylashtirish uchun dizaynlangan va ergonomik dizayni operatorning xavoti yo'qotishini kamaytiradi, shuning uchun ishlab chiqarish jarayonida maksimal effektivlik ta'minlanadi.

Uchta Tezlikli Avtomatik Hidrolik Jadval Dripper Bulb Inieksiya Forma Mashini Plastik Ishtirok Mashini - bu turli xil forma jarayonlar orqali ko'p turdagi plastik qismlarni ishlab chiqarish mumkin bo'lgan keng qabul qilinadigan mashinadir. Mashinaning ABS, PC, PVC va PP kabi turli xil to'qim sovrallaridan foydalanishi mumkin. Bu xususiyat, plastik ishlab chiqarish sanoatiga kirishni xohlagan har qanday biznes uchun yaxshi sarmoya hisoblanadi

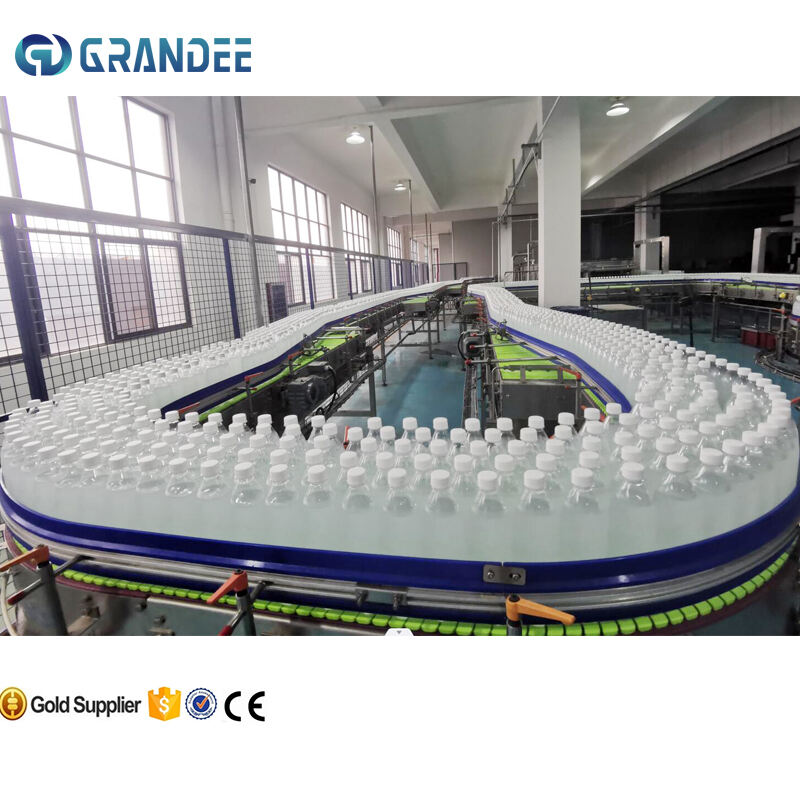

GRANDEE MACHINE zhangjiagang shahri, Xitoyning Shangha yordamida joylashgan. Dunyodagi suv paketlash mashinalari sohasida ekspertizm o‘rgatamiz. Kengaytirilgan standart ish xonamiz 10,000 kvadrat metr bo‘lib, mijozlarga turli xil mahsulot ishlab chiqarish, inzheneriyaviy dizayn, konsultatsiya, texnik xizmatlar va boshqa integrallangan EPC yechimlarini taqdim etamiz.

Mashina xususiyatlari:

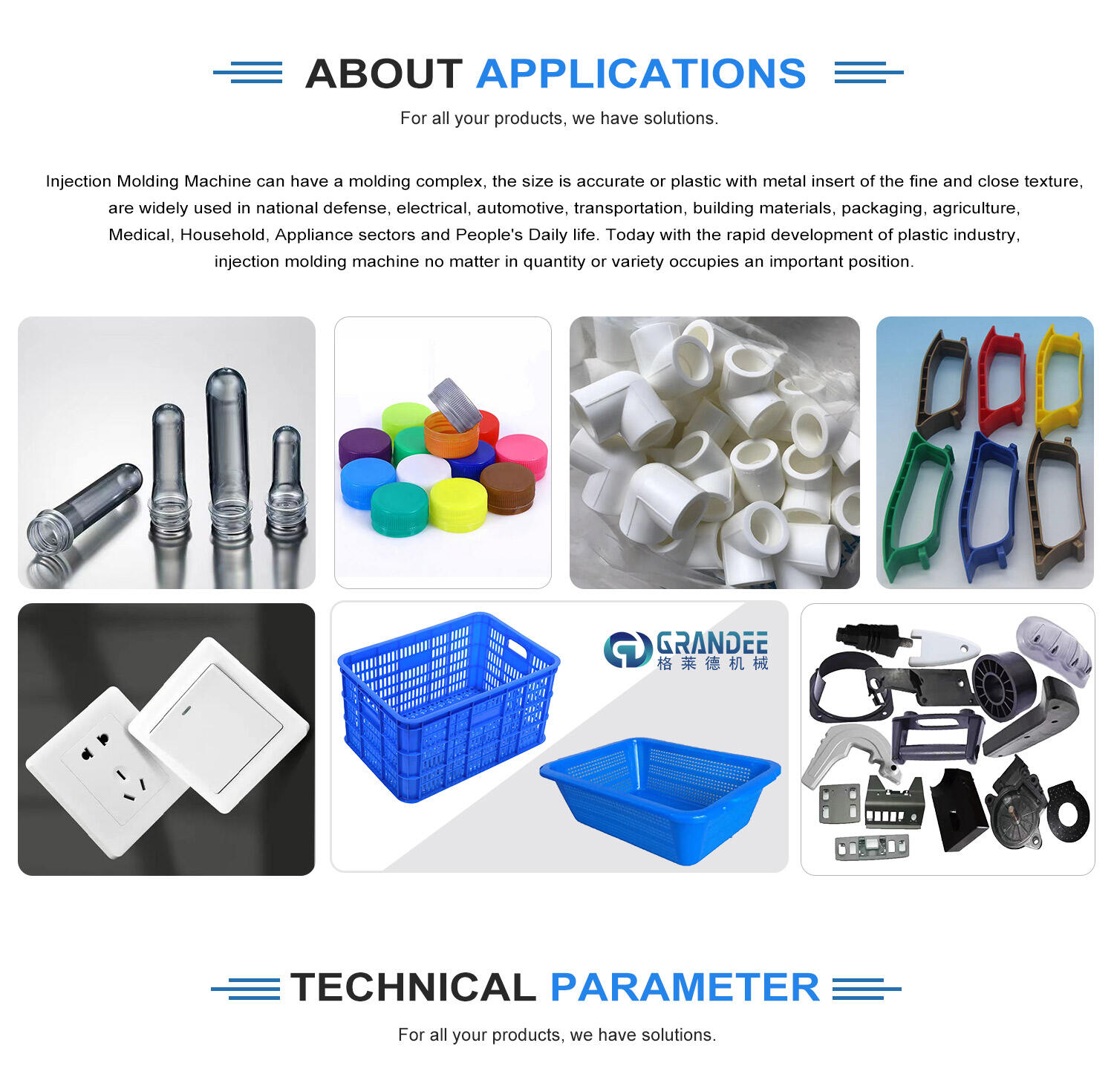

Inketsiya mashini umumiy ro'yxatda inketsiya tizimi, shunga qo'shnish tizimi, hidravlika sur'ati tizimi, elektrik kontrol tizimi, yoroshlangich tizimi, ishtirok va sochilish tizimlari, xavfsizlik monitoring tizimlari va boshqa komponentlardan iborat. Inketsiya mashinining ishlash printsipi inketsiya shiringa bilan o'xshaydi, bu butun plastifikatsiya qilingan (ya'ni, voqei holatida) plastik material uchun yopiq shablon maqsadga yetarlicha tortib berilgan tortib bo'yicha tortib berilgan tortib (yoki pishloq) orqali tortib beriladi. Inketsiya - bu takrorlanadigan jarayon, har bir tsikl quyidagilardan iborat: miqdoriy taomlash-mol polimer plastik bosim ostida inketsiya-shablon to'ldirish-sochilish-shablon ochish va mahsulotni olish. Plastik qismlarni olgandan so'ng keyingi tsikl operatsiyasiga o'tiladi

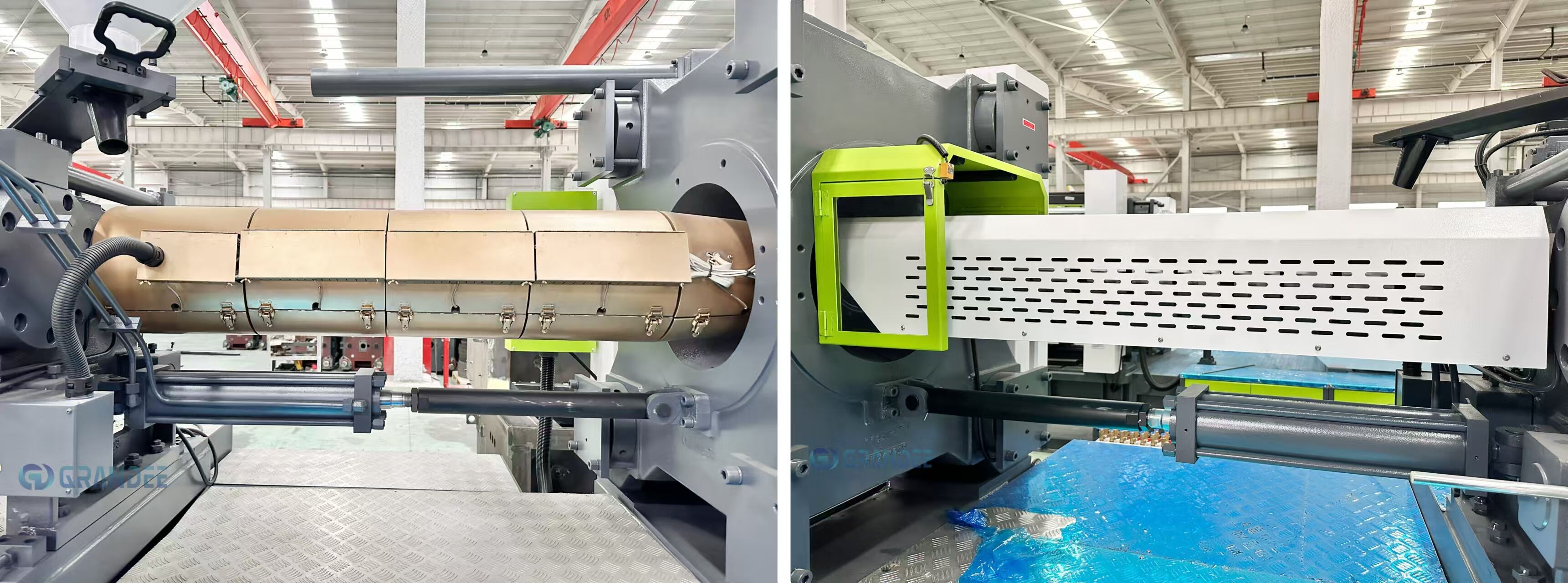

Nanometr infrakrasni issiqdiriltma yuzi:

Nano infrakrasni issiqdiriltma yuzi yaxshi isolatsiya effekti, kichik issiq yo'qotishi, tezroq issiqdiriltma, tezroq ta'minlash. Shu asosda hidravlika musuvchi qo'shilgan, bu materialning chiqishi oldini oladi

Shunga qo'shnish uniteti:

modular optimizatsiya dasturi orqali ishlangan 5-noktalik ikkilavashli shunga tizimi. Tez va qat'iy shunga holati bilan muvofiqlik etish uchun kuchli va tez shunga. Hidravlika erga sistemasi yordamida tez va o'zgaruvchan kalip balandligini tartiblash. Konservativ shunga kuchi bo'yicha kalip balandligini avtomatik tartiblash imkoniyati mavjud

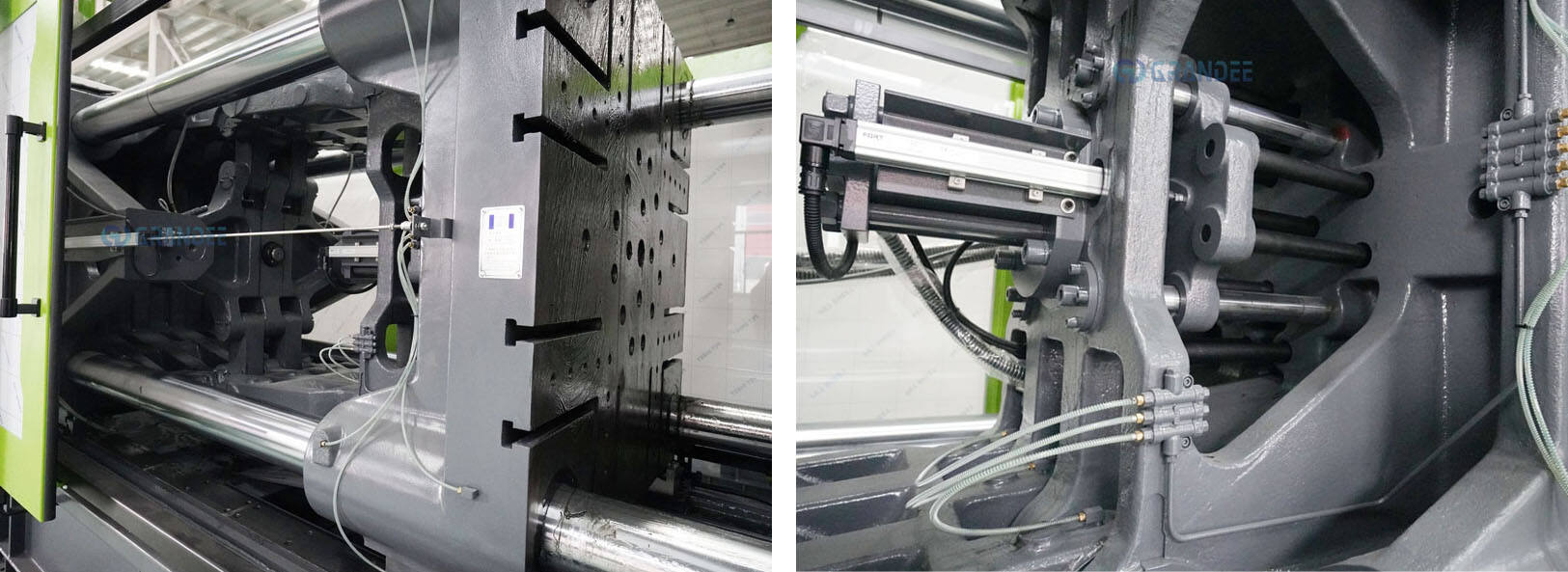

Egirmon biryordam:

Tenglamachilik doyirlarini egirmon davomida tez egirishda qabul qilish uchun muvofiqlashtirilgan doyirlar bilan muvofiqlashtirilgan tekislikni ta'minlash texnologiyasi. Katta og'irlik bilan besh yulduzli hidravlika motori. Imlo holatiga qarab turli xil egirmon sharti uchun turli egirmonlarni tadqiq qilish va rivojlantirish, progressiv talablar uchun muvofiqlik va egirmon sifatini ko'tarish

Boshqaruviy unit

Ko'plab funktsiyalar va aniqlik nazorat jarayoniga ega import qilingan kompyuter Egirmon mashinasi uchun. Duniyodagi mashhur elektrik komponentlari va sifatli muloqot apparati tez va ishonchli ishlaydi

|

|

|

|

Shunga qo'shilish kuchi, KN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Yo'q |

Ism |

Brand/Material |

ASLI |

1 |

Vituska/bo'r |

Ouwei/Fuyi/Tongda, 38CrMoAL |

China |

2 |

Uch qabta va injeksiya boshlig'i, ikkinchi pleyta |

QT500 |

China |

3 |

Servo motor |

Synmot |

China |

5 |

Hidro motor |

Delson |

Italiya |

6 |

Chizg'i shakli vilka |

Honeywell\/OMRON\/Panasonic |

AQSH\/Yaponiya |

7 |

Havo perkusiya |

SCHNEIDER\/LG |

Fransiya\/Koreya |

8 |

AC kontaktor |

Shnayder |

Fransiya |

9 |

Termik relé |

Shnayder |

Fransiya |

10 |

Nazoratchi |

TECHMATION |

Tayvan, Xitoy |

11 |

Elektron ichki chizg'ich |

Jiesheng |

AQSH |

12 |

Pompasi |

Oufeite |

China |

13 |

Solenoid valv |

YUKEN |

Yaponiya |

14 |

Maslo yopqich/yuzoq yopqich |

VALQUA/HALLITE |

Yaponiya/Ingiltir |

15 |

KDAS xarajat qog'ozi |

HALLITE |

Birlashgan Qirollik |

16 |

Servo regulator |

Mengde |

China |

Barcha bosqichlardagi yechim

Birinchi yoki ikkinchi bosimli R.O. suv tozalash tizimi

Asl suy qutusu → Asl suy pompi → Kuvarsqo'sh filter → Faol уголь filter → 5 mikron filter → 1 mikron filter → Yuqori bosimli pompi → Boshlang'ich revers osmos uskasi → Orta suv qutusi → Ko'taruvchi pompi → (Ikkinchi yuqori bosimli pompi → Ikkinchi revers osmos uskasi) → Ozon mixeri → Toza suv pompi → Toza suv qutusi → Tashqi ta'minot pompi → Titanyum tube filter → Tashqi ta'minot → To'ldirish mashinasiga

Avtomatik OPP BOPP issiq yoqlig'i bilan label qo'yish mashinasi

Avtomatik BOPP etiketlelash mashini konteynerlar va etiketlar uchun turli materiallardan foydalanishga qaramasdan bog'liq. Har bir etiketning narxi nisbatan past, bu turli xil turdagi konteynerlarga ega bo'lgan foydalanuvchilar talablariga javob beradi. Bu kengaytirilgan ishlab chiqarish va integrallangan operatsiyalar uchun eng ekonomik modellardan biridir. Texnikada modullarlangan dizayn tushunchasi keng tarqalgan, bu foydalanuvchilarga shaffof va oddiy ravishda butaklarni almashtirish imkonini beradi. Yulduzcha davrlari, yo'naltirish pleytlarini almashtirish yoki eskisi bilan tezlikni automatik ravishda boshqarish kabi, etiketni almashtirish uchun faqat PLC dasturini almashtirish kerak bo'ladi, texnika foydalanuvchilar uchun va foydalanuvchilarni hisobga olgan mahsulot tushunchasi hamma joyda ifodalanadi.

Avtomatik PVC PE Shrift Sutqich Etiketlash Mashini

Bu butunlayoq avtomatik sleev etiketlash mashini turli xil turdagi butelkalar uchun muhim, masalan, yuqori butelkalar, kvadrat butelkalar, oval butelkalar va boshqalari. Ushbu mashinaning filmlarni avtomatik ravishda ta'minlash va kesish imkoniyati mavjud, shuningdek, etiketlarni to'g'ri joylashtirishi mumkin, bundan sabab, ish kuchini ko'p kamaytirib, ish effektivligini oshiradi. Mashina ichki ichimliklar uchun ham, kosmetika butelkalari uchun ham, shampon butelkalari uchun ham qo'llanilishi mumkin.

Paketlash mashinasining ishlangan principi

Bitta qismli film yopish mashini paketlash filmining issiqdan chiqarish xususiyatlari asosida ishlaydi. U photoelektrik perizod sensorlaridan foydalanadi onlayn tekshirish uchun. Yig'ilgan signallar PLC (dastlabki programm bilan boshlang'ich) dasturi orqali boshqariladi va ishlash jarayonida. Tashqi band传送 belt butelkalarni davom etuvchi ravishda taqdim etadi, ularga ajratilgan bo'limlar beriladi va bosim mekanizmi orqali barcha jarayonlar amalga oshiriladi, jumladan, butelka qoyish, davom etuvchi sur'atda sur'shib borish va butelka, bitta film bilan yopish, filmni tanlash va shakllantirish, issiq orqali yopish va sochish va shakllantirish

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM