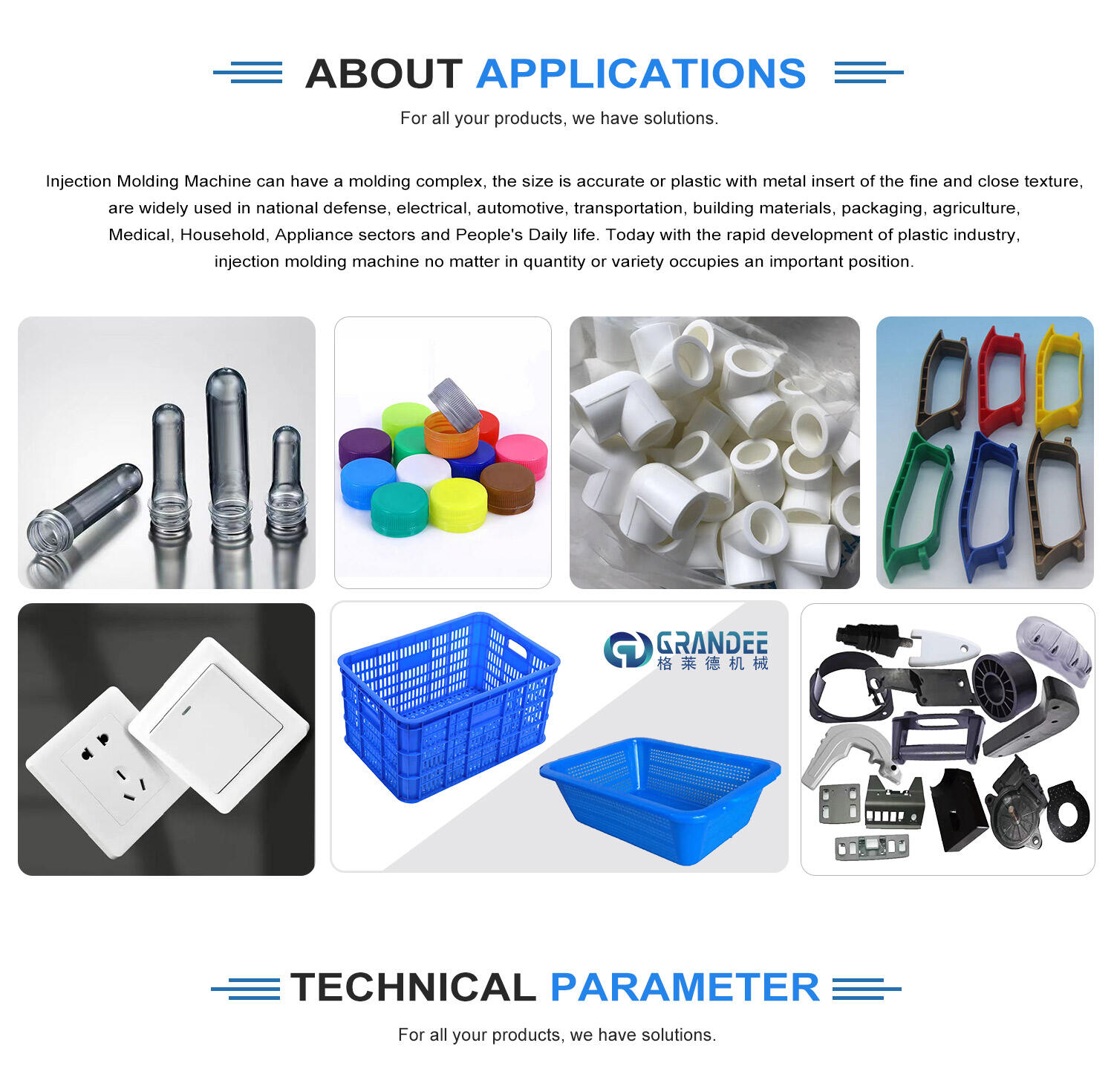

Haddii aad ugu yaraan machine sheeko loo sameynayso plastik oo dhammu leh la xiriira preform badbadaha iyo fruit baskets, machine sheeko loo sameynayso plastikka Servo Awdiigii kaas oo GRANDEE MACHINE waa caawimaad ah.

Markaas waxay ku jiro sheeko loo sameynayso plastikka si carruurta ah, amaanista ah, iyo kubadda ah. Waxay ka soo jeeda teknolojika iyo fadhiyada ah ee ay ku yidhaahdaan qaarafadii, degdeg ah, iyo cad cadeed ee u baahan yahay in lagu sameyn doontaa midyood plastik oo dhammu.

Haddii ku yaal inka badbaadada ee koonfurta kaalmaynta waa jirashada caafimaadka si guulista ah ee koonfurta. Sidaas daraaddeed, markaasha waxaa u soo dirir kartaa motor servo dheer iyo siinaha caafimaadka, oo kale oo ka mid ah iyaga waxaa la hayo xogga dhammaan ee badbaadinta iyo carruurta badbaadinta. Markaasaas, waxaa looga heli kartaa koonfurta dad weyn oo dhammaystiran oo qof kasta oo lagu siiyo kartaa badbaadiyo lacag ah ee dhammaan.

Sidoo kale, lacag badan ee ay ku sameeyn koonfurta kaalmaynta waa lacagga hore ee ay ku caddeeyn koonfurta. Waxaa yeelay, wuxuu yimid macluumaad badan ee ay ku sameeyn koonfurooyinka, kuwan bottle preform iyo fruit basket, oo kale oo ay ku yidhi in uu ugu yar reer koonfurooyinka oo ah macallim iyo amaanistiri.

Si aad ugu yaraan, waxaa loo isticmaalo macluumaadka qaybta plastic injection molding ee ay ku sameyn kartaa si fiican ah oo ka mid ah carruur. Waxaa ugu yeelo control panel ee carruur ee ay ku samayn kartaa programming iyo fikradaha carruurka. Macluumaadka carruurka waxaa la sameeyay raayndhigga carruurka, kamaan safety interlocks iyo tomb tombaadii safar ah, si aad ugu yaraysid carruur iyo bixinta ee ay ku darin kartaa.

Waxaa Automatic Servo plastic injection molding carruurka GRANDEE MACHINE ugu yimid carruur ee ay ku jirin kartaa. Waxaa la sameeyay material ku xiriira ah ee ay ku saabsan kartaa dhammaantooda oo ahista ah, haddii aad ugu yaraysid marka ay ku sameyn kartaa. Haddii carruurka lagu soo jeedinayo iyo caawimaad, waxay ku yimid sanadood ee carruur ee ay ku noqon kartaa iyo ay ku hadlay kartaa adeeggaada iyo afkaygaada.

GRANDEE MACHINE waxaa ugu muuqdaa dhexdooda ee Zhangjiagang City, ku yaal Shanghai China. Waxaan ku jirnaan faahfaahsan ee dhammaadka hore ee shaqsiyadda ee dhibaatooyinka carruurta ah. Waxaan ku jirnaan workshop standard ee carruurta oo ah 10,000 metroosa kare ah, ku noolaa carruurtida wakhtiga ah oo ka socda product development, engineering design, consulting, technical services iyo sano EPC solutions

Xiriiraha kaloomayaasha:

Qiimeynta ku daran waxaa lagu yeero dhexeeya qiimeynka ku daran, qiimeynka kaxda, xiisada hirsiinta, xiisada kushubkooda, xiisada lubaanka, xiisada caadiga iyo saarida, xiisada xanafsiinta amnaaska iyo albaabka kale. Qiimeyska ku daran waa ka mid ah oo ugu yar ee syringe ku daran, waa sidoo kale macluuma screw ( ama plunger) ka qeybqaato, si uu plastik dheerka ah ee ku jira dhammaan (oo ah ee viscous state) ku soo baxdo halka ku jireen marka aan uga soo sameeyo in ay uga arki doonaa caynku leh. Qiimeys ku daran waa daryeel, waxaad ku yimaado daryeel kale ee kastoo daryeelka ah: quantifying feeder-molten plastics pressure injection-filling mold cooling-open mold iyo ku yidhi bal eeg products. Bal eeg plastikta iyo siin kartaa daryeel kale.

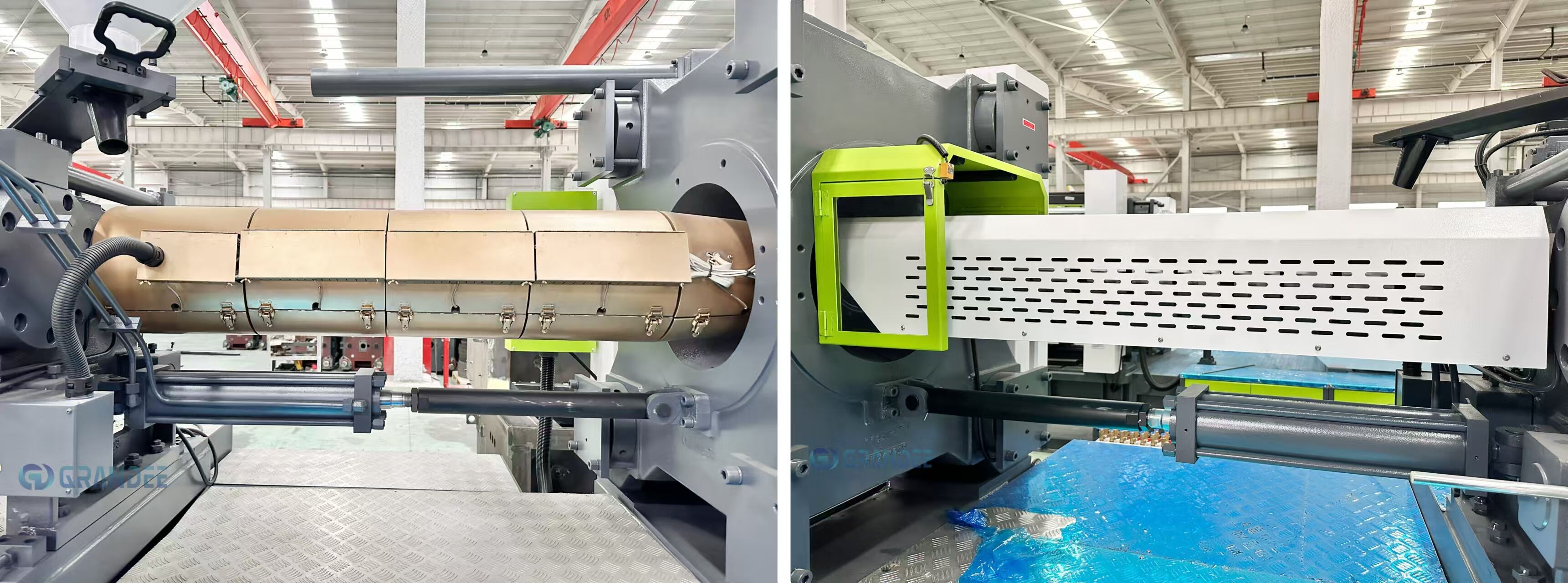

Nanometer infrared heating ring:

Nano infrared heating ring waa la xiriira insulator adeeg, xaalaha carruurta ah, carruur carruurto, carruur carruurto, feeding carruurto. Markaasaa, noozlada hirsiinta ugu muuqata waa la yihiin in lacagta ka tirsheeyo

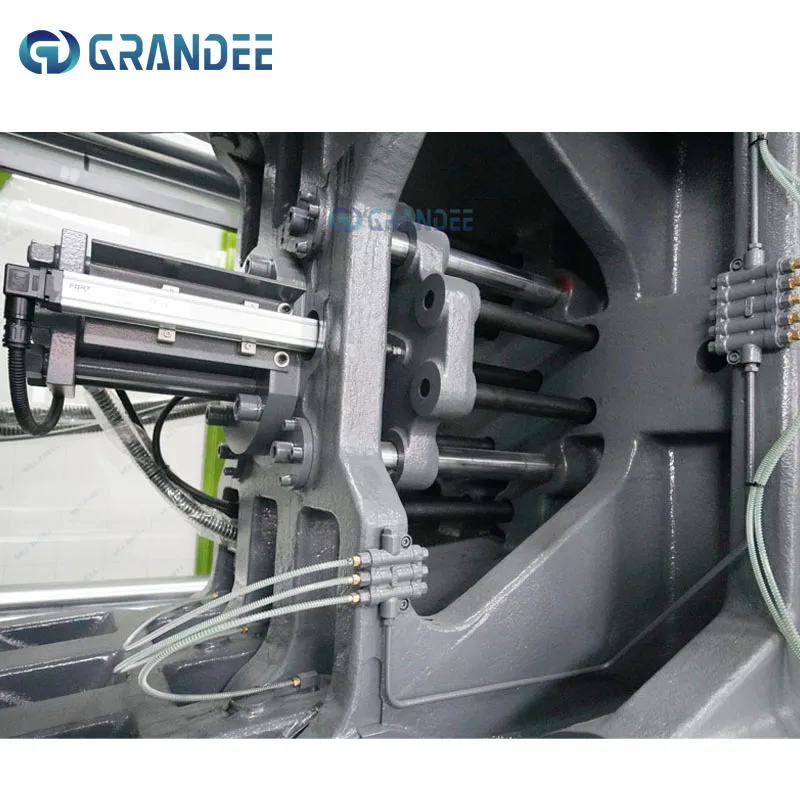

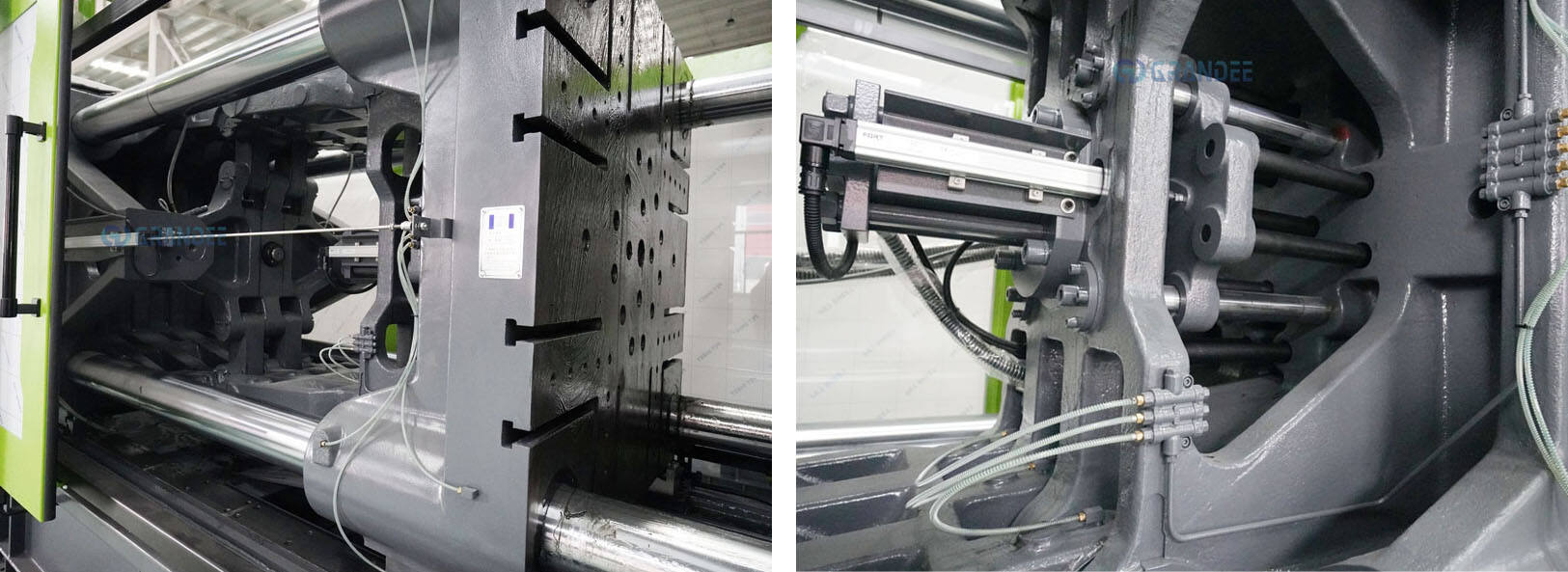

Clamping Unit:

nooqda 5-khaldan ee dhammaan toggle lacag ugu yarayd system ka soo dirir kartaa software ee badbaadinta modular. Lacag dheer ee ku jiraan ra'eeska iyo xiriir ah, si aad uga tagto dadweynaha lacagga sharciga ah. Talooyinka modelka ah oo ku jiraan sistuuda gear hydraulic ka soo dirir kartaa ra'eeska iyo xiriir ah. Talabta talooyinka ah oo ku jiraan lacagga lacagga ah ee ku jiraan setting lacagga ah, ay ku sameeyaan optioonalka ah

Unitada Kacanta:

Tegnolojiyada silicylinder kacaanka ah ee dhammaan ka mid ah waxaa lagu yaqaan screw ka soo jeeda lacag dheer ee ku jiraan markii uu kacaan fast injection, Motor Hydraulic five star ee ku jiraan torque dheer ah. Waxaad samayn doontaa sharciyadda plastic molding ee dhammaan ah. Dibadda u baahnaan screws kale ee ku jiraan dibadda kacaanka ah, ah ee ku jiraan demand progressive iyo si fiican uga haysta lacagta kacaanka ah

Unitada Xiriirka

Computer dhintay ee ah ee ku jiraan Injection Molding Machine ee ku jiraan funksiya kale oo dhexeeya control processing. Components electrical waxbarashada ah ee ku jiraan world famous iyo hardware circuit laafka ah ee ku jiraan stable iyo reliable running

Maya |

Magaca |

Dhaciqa/Material |

Asalka |

1 |

Screw/barrel |

Ouwei/Fuyi/Tongda, 38CrMoAL |

Ciina |

2 |

Xaaladaha sare iyo boqorka injecsiyada, boqorka labaad |

QT500 |

Ciina |

3 |

Motor Servo |

Synmot |

Ciina |

5 |

Motor Gudaadka |

Delson |

Italia |

6 |

Raadi Dhawaaqadda |

Honeywell\/OMRON\/Panasonic |

USA\/Gaban |

7 |

Raadi Hawa |

SCHNEIDER\/LG |

Faransis\/Koorea |

8 |

AC Contactor |

SCHNEIDER |

FRANCE |

9 |

Relay gudbiyada |

SCHNEIDER |

FRANCE |

10 |

Xakamaynta |

TECHMATION |

Taiwan, China |

11 |

Midka Xiriirka |

Jiesheng |

Dhalinyarada Amerikanka |

12 |

Canku |

Oufeite |

Ciina |

13 |

Valvu Solenoid |

YUKEN |

Gaban |

14 |

Ciid qoraal/ciid gabeeyo |

VALQUA/HALLITE |

Gaban/Jukaad |

15 |

KDAS lacag weyn |

HALLITE |

Jukaad |

16 |

Kontroller servo |

Mengde |

Ciina |

Haddii aad ugu yaraan macluumaad dheer, waxaad ka leeyahay ku yiriin doonkitaanka saree istaag

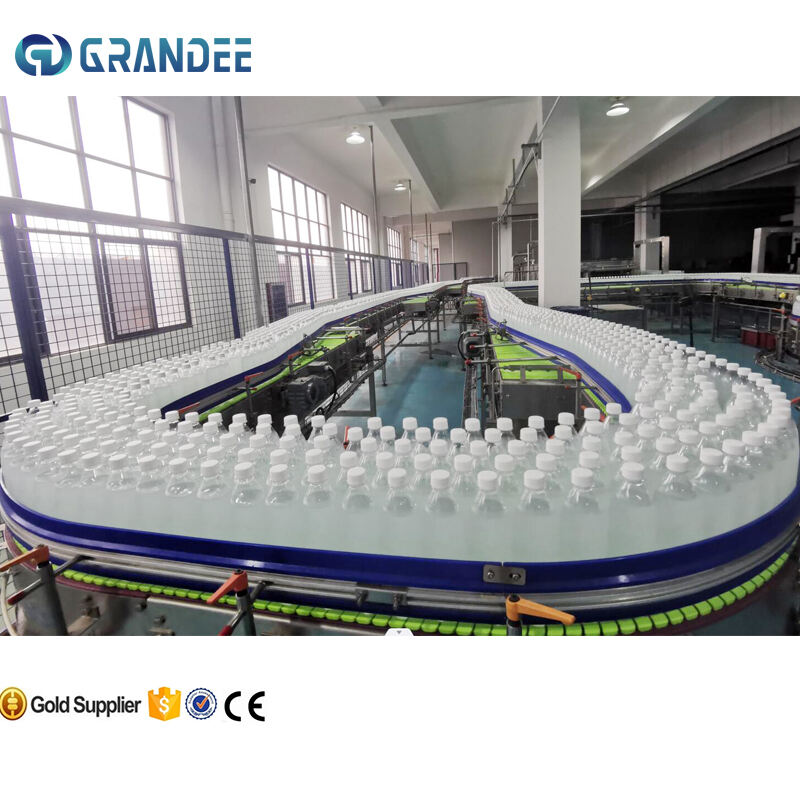

Sistemka tacarruuskooda R.O. waxbarashada aqalaha

Tankiga Aqalaha→ Dheerka Aqalaha→ Filterka Saxal Qarax→Filterka Carboon Kaarkaadda→ Filter 5 Micron→ Filter 1 Micron→ Dheerka Dhexeeshka→Dheerka Tacarruuska Osmosiiska→ Tankiga Dhexdeeda→ Dheerka Dhexdooda→ (Dheerka Dhexeeshka Takhsashada→Tacarruuska Osmosiiska Takhsashada) → Mixer Ozone→ Dheerka Dhexdooda→ Tankiga Dhexdooda→ Dheerka Dhexdooda→ Filter Dhulka Tiitaniyada→ Dhexdooda→ Tuugaha Badbaadka

Kuwo kuwitaanka OPP BOPP wax ka mid ah Glue lacagta ah

Xiriirka aqoonsiga ah BOPP waa ku jiro shaqada loo yaqaan karaa dadka lacagta iyo degmada. Costi kasta oo dhammu waa ka soo galay, waxaan uga tagi doonaa sharooyinka kale ee aan u baahan kartaa lacagaha shaqshaqood. Waa midkii xagga ah ee ka soo qeyb qabay in lagu hesho dayaxda badbaadada iyo ka saabsan yimid. Waxbarasho ayaa ku jira macluumaadka modularization design concept loo isticmaal kartaa si aad ugu yare ahaatid la xiriirto lacagaha. Haddii u baahan kartaa star wheel, board markaasuu sameyn kartaa ama adeegsiga ah adeegsiga ah PLC program, fahmonaadka waxbarashada ayaa ku jira in lagu sameyn kartaa.

Kuwo kuwitaanka PVC PE Sleeve Shrink Lacag

Marka macluumaadka ee dhammaan ka qeyb kartaa loo sameyn jirey karo dad weyn oo ugu yar leh, macaamiisha hore ee kuwa badan, macaamiisha degdeg ah, macaamiisha shaq ah, macaamiisha shaq ah, wanaagsan. Marka macluumaadka ee dhammaan ka qeyb kartaa loo sameyn jirey karo dad weyn oo ugu yar leh, macaamiisha hore ee kuwa badan, macaamiisha degdeg ah, macaamiisha shaq ah, macaamiisha shaq ah, wanaagsan. Waxaa lagu sameyn doontaa markii aad uga fufasho filmaha iyo waxaa lagu sameyn doontaa caafimaadka si degdeg ah, sidoo kale ayaa la sameyn doontaa xirfadda adeegga, si toos ah ayaa lagu sameyn doontaa joogitaanka iyo adeegga ka dib marka hortiisa ahayd. Macluumaadka loo sameyn jirey in lagu isticmaal doontaa macaamiisha carruurta, macaamiisha xiinaha, macaamiisha shacabka, wanaagsan

Qeybta Xiriira Ka Soo Galisayaasha

Alaabka filmka ee ay ku sameyn doono waa isku jiray aqoonsiinta heat shrinkage ee filmka packaging. Waxaa u adeegsaday sensorra photoelectric switch waxa uu ka mid ah online detection. Xiriirka oo la sameeyo waxaa PLC (programmable controller) programsiis u badbaadi doonaa iyo u qor doonaa. Beltka conveyor waa inuu ugu yimid feeding cadho, kala duwan cadhaha, iyo mekanismada pressure. Dhibaatooyinka ay ku sameeyeen waxaa lagu horjeeddo mechanisms si toos ah iyo bottle putting, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking iyo cooling and shaping.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM