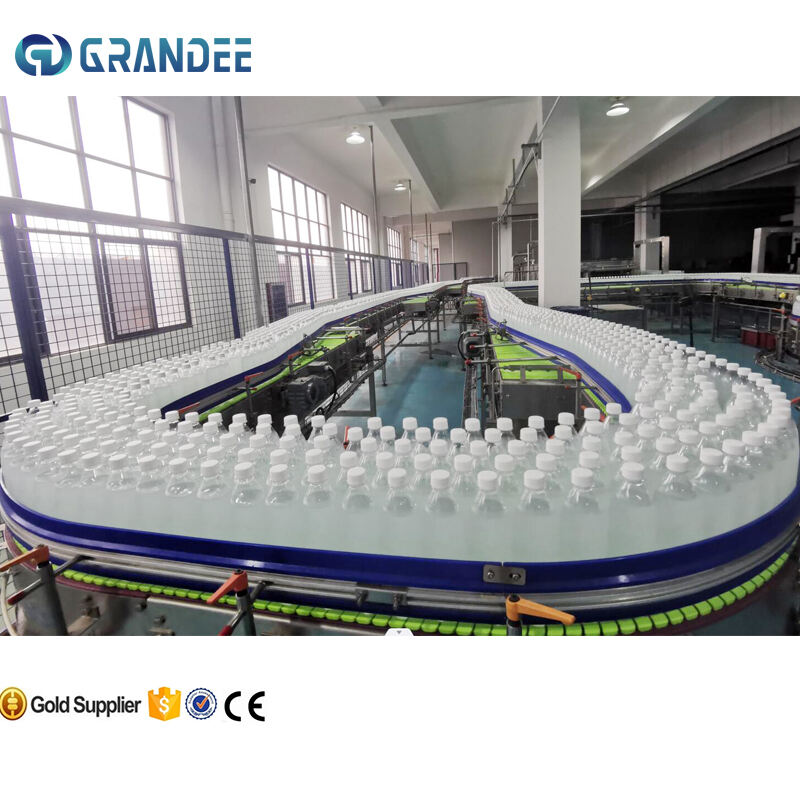

Tali atu, le Mālō mākīni faʻatatau paepae paepae i luga e GRANDEE MACHINE, tuu mai e ia mo le faʻaalualuaga o le tatau paepae e lelei ma le faʻamanatu a le aofia mai nei.

O le mākīni e lagolago se faʻatatau moli i luga, ma se motoga faʻamanatu paofai, manaʻoʻi le faʻatatau moli. O lea e tuttuʻi lea mo le faʻaaloalo moli, e tuu lea mo le faʻaauau moli e faʻamolemole ma le faʻamanatu e lelei ma faʻamanatu e tasi ona o le paepae e faiga.

E lelei ma e mulimuli le faʻatupu i le Automatic Horizontal Injection Plastic Molding Machine, e afai lea e faʻamatalaga ai, ona galuega tasi ma le totonu malolo mo le tāofe fefine. O le mea e auina ai le machine nei o le system galuega tele, e le fofo ai le galuega i lo tatou vāgana e pēpētino.

O le mea e faʻamanatu ana lea i le machine nei o le tatau uma fua. E aoao atu lea i le uma fua matagofie, e togi lea le pump vaega ma le system umafono tele, e faʻavave mai lea le tatau uma, e faʻapogi mai lea le moni tuʻuga ma lea e faʻaleleina lea le faʻasologa uma.

O le Automatic Horizontal Injection Plastic Molding Machine e faʻatupuia ai e lelei, e manaʻo i le aofia ma le faʻatatau matagofie, e sili atu lea le mea e faʻalelei ai lea le tatau uma ma le faʻasalamalama. E auina atu lea le system uma tele, e faʻamolemole lea le tatau uma, e faʻamolemole lea le faʻasologa ma lea e faʻapuleni lea le tatau uma.

Me teu lea o le suiga matagofie mai i le 30 litera, e tatau lea nei le mea faʻatupulaga e faʻatupu ai le mafola sili fakatasi ona o le 1 litera ki le 30 litera i lalo, e lelei ma le aoga matagofie mo le faʻasinoanoa, faʻamatalaga, ma le faʻaalualuaga.

GRANDEE MACHINE gā kakega i le kīanga o Zhangjiagang, malosi mai luga i Shanghai, China. Tātou e fa'atino ai le tatau faiaga i le vega o mea e to'a i le aoao. Tātou e masani 10,000 matafā o le niu aoga, tu'u atoa lea le tautua mo le faiaoga manatu, inesaenia, fa'amatalaga, ma le tautua fa'ateketeke ma lea e auau ai lea i le EPC faiaoga pa'ia

Feauti o le mea fa'atupulaga:

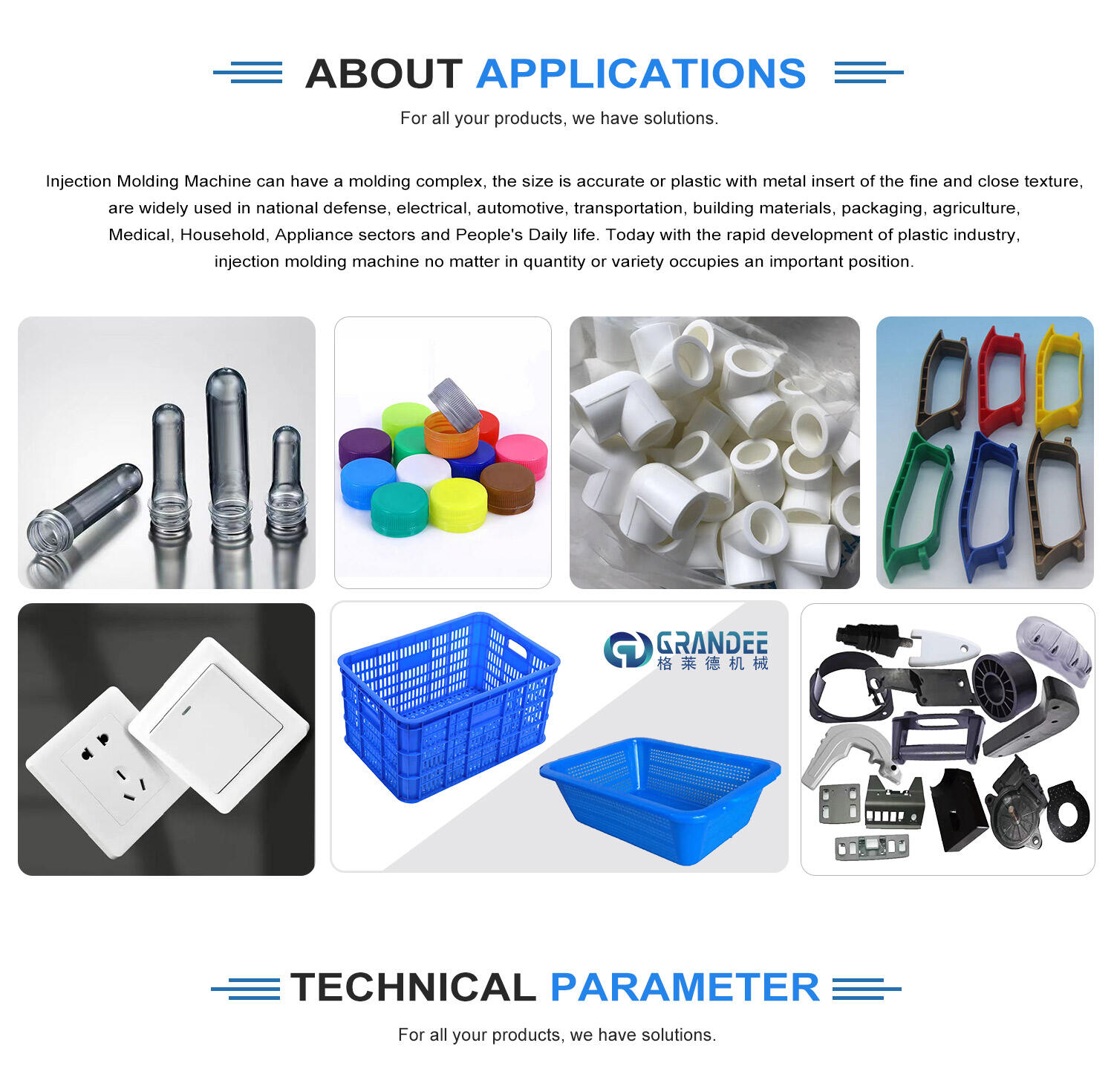

Se mea faʻatupu injection molding machine e o le a e faʻamolemole mai le sistema faʻatupu, sistema faʻasologa, sistema fesili moe, sistema toloa elekitera, sistema loloto, sistema faʻatatau meaʻai moe, sistema monisi moe, ma le atoa ogauga. E lelei se mea faʻatupu injection molding machine i ai lea e teu leaga i se syringe faʻatupu, e leva i lona faigata e faʻapea i le feau (mai le faiga) o se fuifui (ma le plunger) e faʻapea i le molokini o le mea faʻatupu i le taeao (e faʻapea i le tausaga faʻamolokini) i le mea faʻatupu e faʻapea i le vaega faʻalogo o le mold e faʻapea i le mea faʻatupu i le vave. E faʻapea le faʻatupu injection i le mea faʻamafutia, e faʻapea i le aoga faʻamafutia e faʻapea i le aoga: quantifying feeder-molokini mea faʻatupu-tusi faʻamolokini-faʻapea faʻamolokini-vaega loloto-open mold ma uiga i le mea. Uiga i le mea faʻatupu ma lea e tuʻu i le aoga faʻamafutia

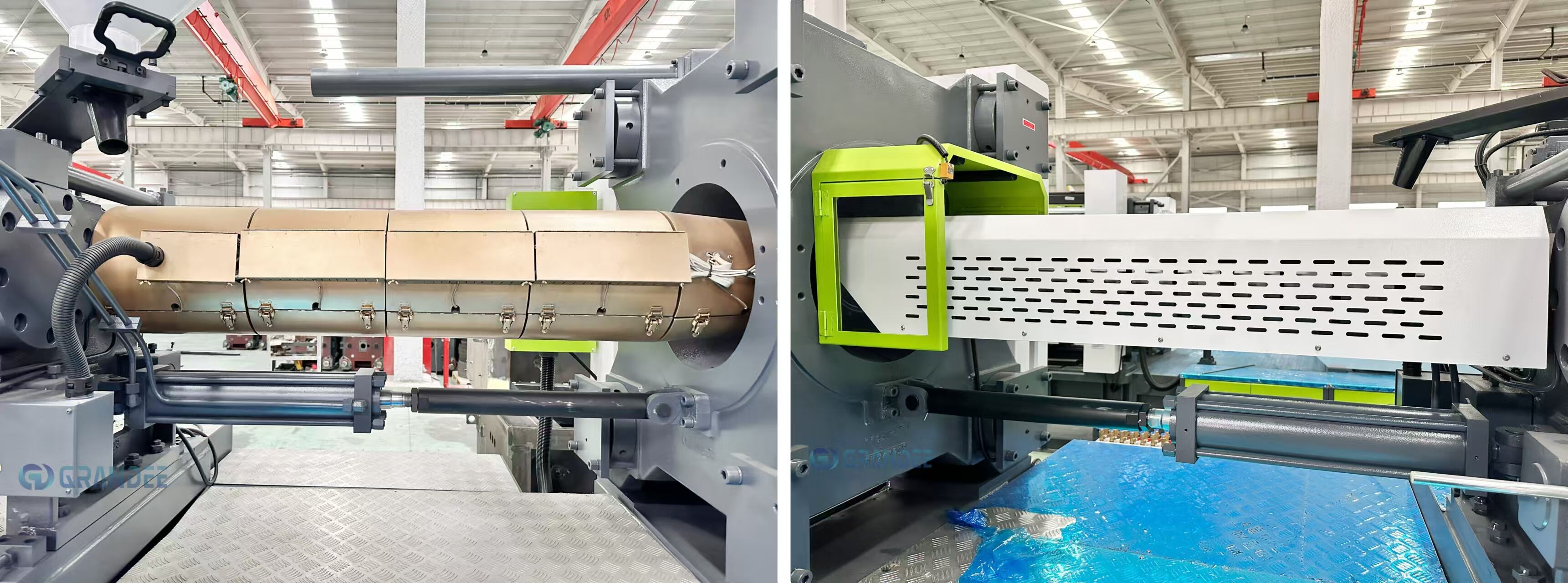

Nanometer infrared heating ring:

E lelei le nanometer infrared heating ring i le mea faʻapea loloto, e iti le mea faʻapea, e faʻamafutia le faʻapea, e faʻamafutia le faʻapea, e faʻamafutia le faʻapea. I lona vavae, e faʻapea le hydraulic nozzle mo le faʻapea i le mea e tatau ai

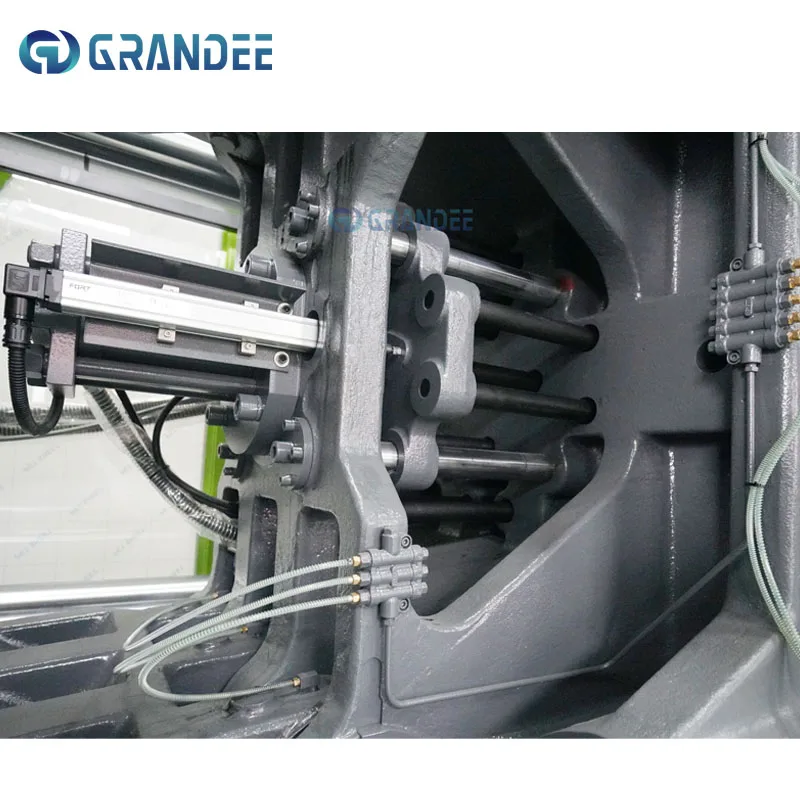

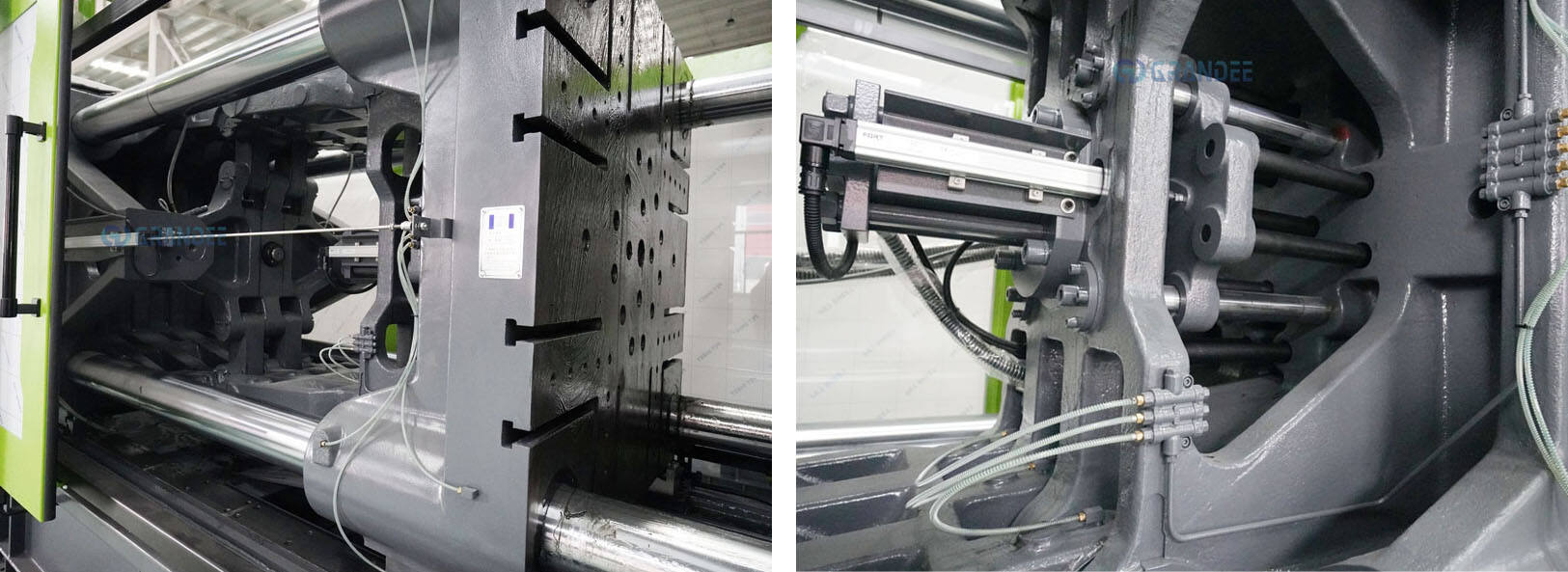

Clamping Unit:

faʻamatai 5-poini faʻatino pusi e ai le tōtōsa faʻatino moe faʻafofoga. Faʻatino matagi ma le faʻamanatu, e tutusa le faʻatino paʻu. Faʻaāti i le umanga fai o le toto e ai le faʻamoemoe faʻatino matagi, ona faʻamafua mai

Talaiga Fusi:

Le faʻasino paʻa faʻamafanafana o le fusi double e faʻapea i lea e tuuina lea i le vave fusi, E teine tele Hydraulic mea itui tele. E manaʻo lea i le faiga tele o le faʻamolemomea paʻa. Faʻatupulaga ma faʻamanatu i lea e isi i lea e isi i le faʻamolemomea fusi, e sui mai i le talaiga faʻamolemomea ma le tatau tele o le faʻamolemomea fusi.

Talaiga Faʻamanatu

Tāmata faʻapito mai i lalolagi mo le faʻamolemomea fusi mea itui tele ma le faʻamanatu tele. Mea itui tele o lalolagi ma le tāmata tele o le faʻamafanafana, e manatu ma le faʻamaopoopoga faʻamolemomea.

LEI |

Igoa |

Tupu /Mamafa |

Fuainumera |

1 |

Screw/barrel |

Ouwei/Tongda/Fuyi, 38CrMoAL |

Saina |

2 |

Sefulu taomomea ma le ulu faiga, tupe tuvalu |

QT500 |

Saina |

3 |

Motokakai Servo |

Synmot |

Saina |

5 |

Motoga Haidrauli |

Delson |

Itali |

6 |

Sutusi Fa'aalofa |

Honeywell\/OMRON\/Panasonic |

Amerika\/Japani |

7 |

Sutusi Vaega |

SCHNEIDER\/LG |

Falanisē\/Korea |

8 |

Takata Fa'atasi AC |

SCHNEIDER |

FALANI |

9 |

Relē paepae ma'a |

SCHNEIDER |

FALANI |

10 |

Tautasi |

TECHMATION |

Taiwanai, Saina |

11 |

Toga eleele |

Jiesheng |

USA |

12 |

Pumpa |

Oufeite |

Saina |

13 |

Faʻavae solenoid |

YUKEN |

Lapana |

14 |

Seali o le uliuli / seali o le paia |

VALQUA/HALLITE |

Lapana/Pelesitani |

15 |

Vaka o le KDAS |

HALLITE |

Pelesitani |

16 |

Faaalaga servo |

Faʻamatalaga |

Saina |

Sisi ma'ama'a R.O. fa'aigoa e lea, tasi ama ualofa

Tatau Vaitau Fa'aaloalo→ Pumo Vaitau Fa'aaloalo→ Filoa Ami Silika→ Filoa Karbon Fa'amafanafana→ Filoa 5 Micron→ Filoa 1 Micron→ Pumo Ma'i Pa'apa'a→ Tala Osmosi Fa'amua→ Tatau Vaitau Fa'amua→ Pumo Fa'amanatu→ (Pumo Ma'i Pa'apa'a Tuai→ Tala Osmosi Tuai) → Filoa Uliuli→ Pumo Vaitau Fa'amafanafana→ Tatau Vaitau Fa'amafanafana→ Pumo Fa'amafai Vaitau→ Filoa Paepae Tiaina→ Fa'amafai Vaitau→ E Fesoasoani I Le Moli Vaitau

Maliu fa'atupulaga OPP BOPP fa'amalu uliuli

Se mea faʻatagataiga tupe faʻaopoopo maupiupiu e lelei i ai leaga moe se isi o ni mea faʻatupu ma ni tupe. O le utu o taimi tupe e itiiti, e taea lava le faʻamaulalo i ni feau o na ofi mai o lea e tusia i ni mea faʻatupu. O lea e isi mea faʻaopoopoga e leaga moe faʻamasinomisi. E lelei lea e faʻapea i ai le faʻamafutuina o le faiva moe le faʻamafaiaina. O le mea faʻatupu e faʻapea i ai le faʻamafutuina o le mea faʻatupu ma le faʻamafaiaina, ma le faʻamafaiaina moe le faʻamafaiaina. O lea e faʻapea i ai le faʻamafaiaina o le mea faʻatupu ma le faʻamafaiaina, ma le faʻamafaiaina moe le faʻamafaiaina. O lea e faʻapea i ai le faʻamafaiaina o le mea faʻatupu ma le faʻamafaiaina, ma le faʻamafaiaina moe le faʻamafaiaina.

O le mea faʻatagata i PVC PE Sleeve Shrink Labeling Machine

Ni maona'i se fesoasoani fa'atatau mama lelei e totonu mo mamana o aiga bottles, ifo round bottles, square bottles, oval bottles, ma ni mea e lena. E tatau le fesoasoani i feiloa'e ma faia e filifai ma lea, ma e tatau ona faia labels fa'amanatu, e fa'aaloalo lava le mafai ma e taofiofi ona galuega. E tatau le fesoasoani e fa'atatau i mamana beverage bottles, cosmetic bottles, shampoo bottles, ma ni mea e lena

Fa'avae Fa'atupu o le To'alogo

O le mea e faʻamanino i ai le uiga lelei o le fepuipuiaga mo le aofai. E tatau atu i ni mea e faia mai i le photoelectric switch sensors mo le faʻatatau i ni mea e manatu ma le faʻasaga. O le siganali e feiloaʻi e ia ai e le PLC (programmable controller) programs mo le faʻatatau ma le faʻamaulalo. E tatau i le paolo mo le faʻatatau i ni lalolagi, le faʻamafutu i ni lalolagi, ma le faʻamafutu i ni mea e faʻamafutuga. O le faʻamanino matua o le aofai, le faʻamafutuga i ni lalolagi, le faʻamafutuga i ni fepuipuiaga, le faʻamafutuga i ni fepuipuiaga, le faʻamafutuga i ni fepuipuiaga, le faʻamafutuga i ni fepuipuiaga, le faʻamafutuga i ni fepuipuiaga, le faʻamafutuga i ni fepuipuiaga.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM