Hvis du leter etter en høykvalitets plast injeksjonsformingsmaskin for å produsere flaskepreformer og fruktkurver, er Automatisk Servo plast injeksjonsformingsmaskin fra GRANDEE MACHINE et utmærket valg.

Denne maskinen er designet for å gi fremragende ytelse, pålitelighet og effektivitet i dine plast injeksjonsformingsoperasjoner. Den er utstyrt med avansert teknologi og funksjoner som sikrer nøyaktighet, konsekvens og fart i produksjonen av høykvalitets plastprodukter.

En av de fremragende funksjonene på denne injeksjonsformingsmaskinen er dens automatiske servosystem. Dette systemet bruker en toppkvalitets servo-motor og drivsystem, som tillater nøyaktig kontroll av injeksjons- og holdningstrykket. Dette betyr at maskinen kan produsere konsekvente, høykvalitets plastprodukter hver gang, med minimale variasjoner i utdata.

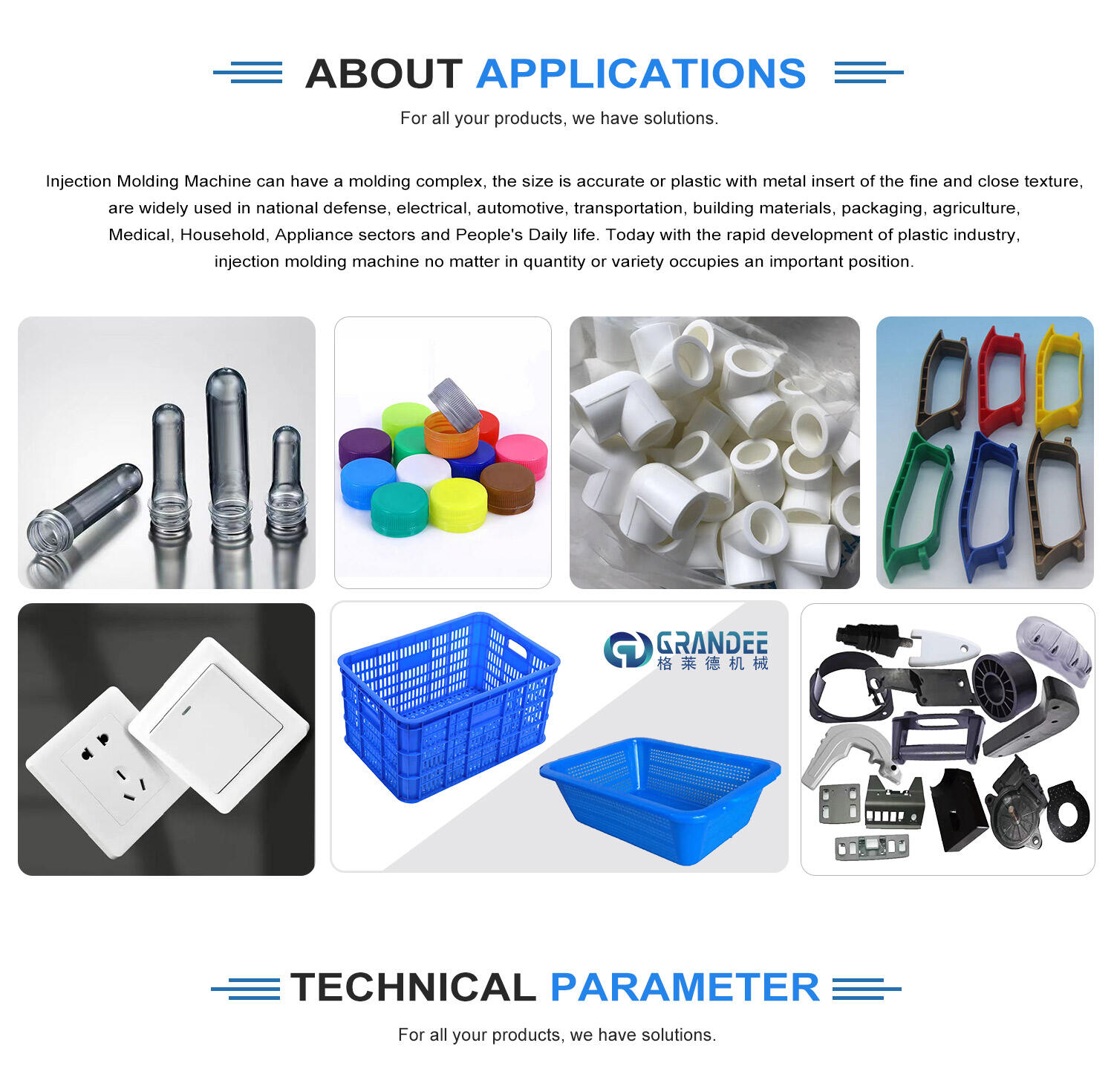

En annen funksjon som skiller denne injeksjonsformingsmaskinen ut er dens brede anvendelsesområde. Den egner seg for å produsere en stor variasjon av plastprodukter, herunder flaskepreformer og fruktkasser, noe som gjør den til en verskelig og pålitelig valg for produsenter av plastprodukter.

I tillegg er denne plastinjeksjonsmaskinen utformet med brukervennlige funksjoner for å gjøre den enkel å bruke og vedlikeholde. Den har et brukervennlig styringspanel som tillater enkel programmering og overvåking av maskinens ytelse. Maskinen har også en rekke sikkerhetsfunksjoner, inkludert sikkerhetslåser og nødstoppknapper, for å sikre operatørens og produktets trygghet.

Den automatiske Servo-plastinjeksjonsmaskinen fra GRANDEE MACHINE er bygd for å vare. Den er konstruert med høykvalitetsmaterialer som sørger for varighet og lengde, selv i de mest kravstillede miljøene. Med riktig vedlikehold og omsorg vil denne maskinen gi år av pålitelig tjeneste og hjelpe deg å øke produksjonen og fortjenesten.

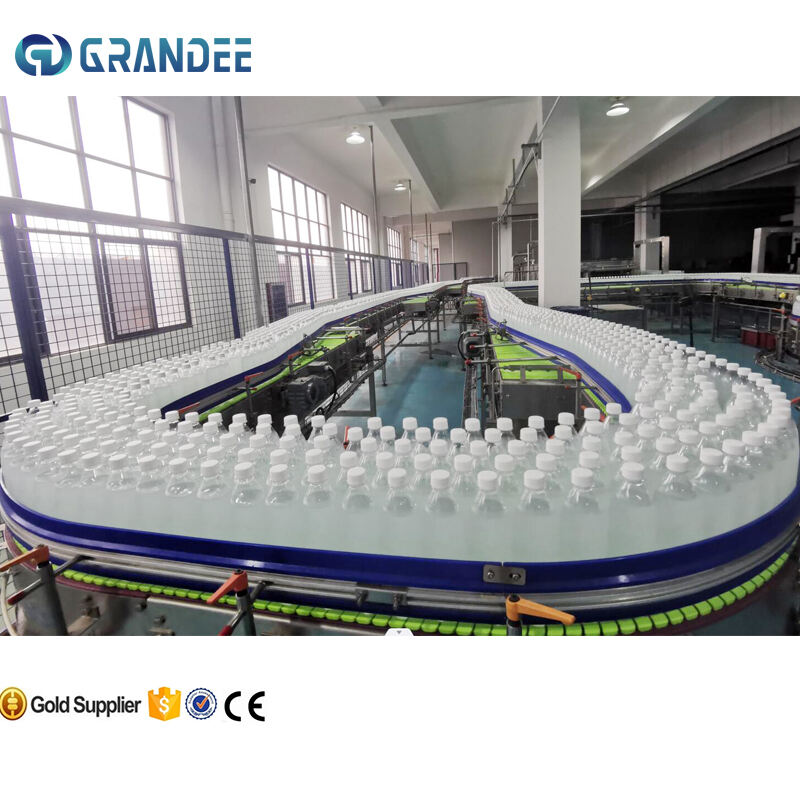

GRANDEE MACHINE er beliggende i Zhangjiagang-byen, nær Shanghai Kina. Vi er eksperter innen feltet for pakking av væsker over hele verden. Vi har mer enn 10,000 kvadratmeter standardverksted, som tilbyr kundene en rekke ulike produktutviklinger, ingeniørforslag, rådgiving, tekniske tjenester og andre integrerte EPC-løsninger

Maskinfunksjoner:

En sprutemaskin består vanligvis av en sprutsystem, klampesystem, hydraulisk drivsystem, elektrisk kontrollsysteem, smøringssystem, varmings- og kjølingsystemer, sikkerhetsovervåkningssystemer og andre komponenter. Arbeidsprinsippet til en sprutemaskin er likt et sprutsyringe; det er ved hjelp av en skrue (eller støter) som gir trykk for å sprute godt plastifisert smeltet (dvs., i klebrig tilstand) plast inn i den lukkede formgjengen for å få formerte produkter etter polymerisering. Spruting er en sirkulær prosess, hvor hver syklus inkluderer: kvantitativt fôring-melting av plast-under trykk-spruting-fylleformkjøling-åpne form og hente produktene. Ta ut plastdelen og gå så inn i neste syklusoperasjon.

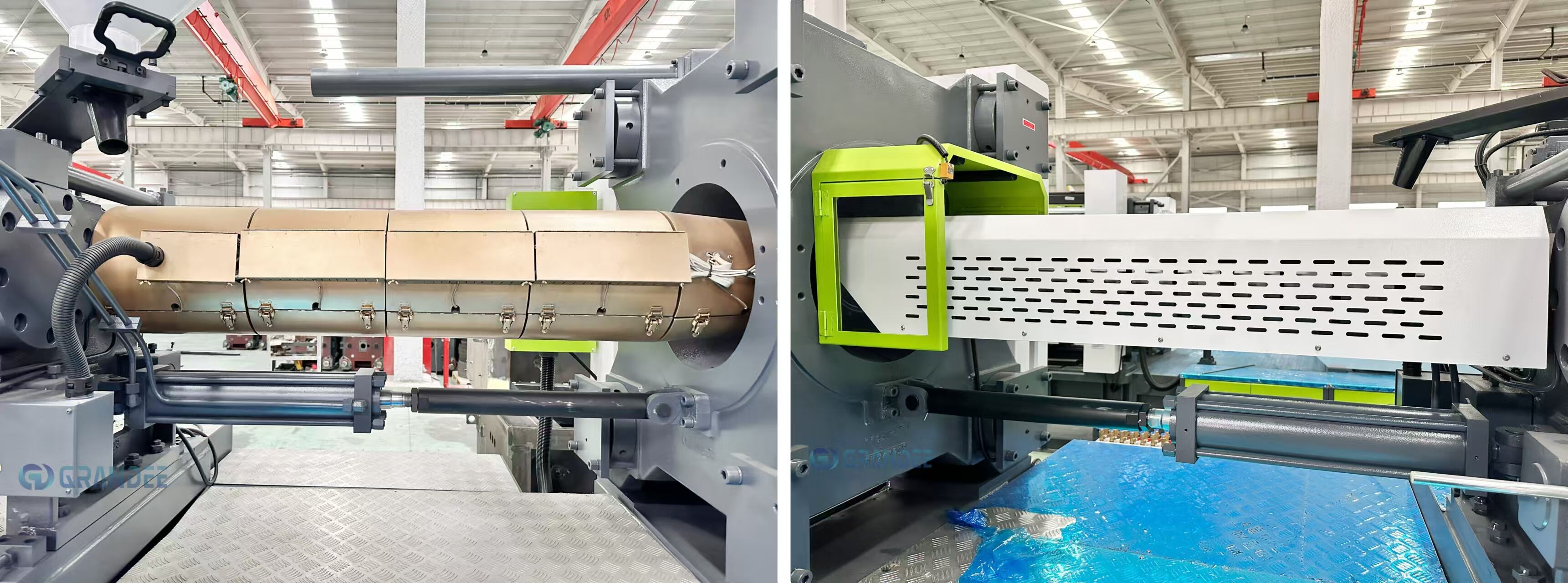

Nanometer infrarød oppvarmingsring:

Nano infrarød oppvarmingsring har bedre isolasjons effekt, liten varme tap, raskere oppvarming, raskere fôring. På denne grunnlaget, er det lagt til en hydraulisk sludd for å forebygge at materialet løper ut.

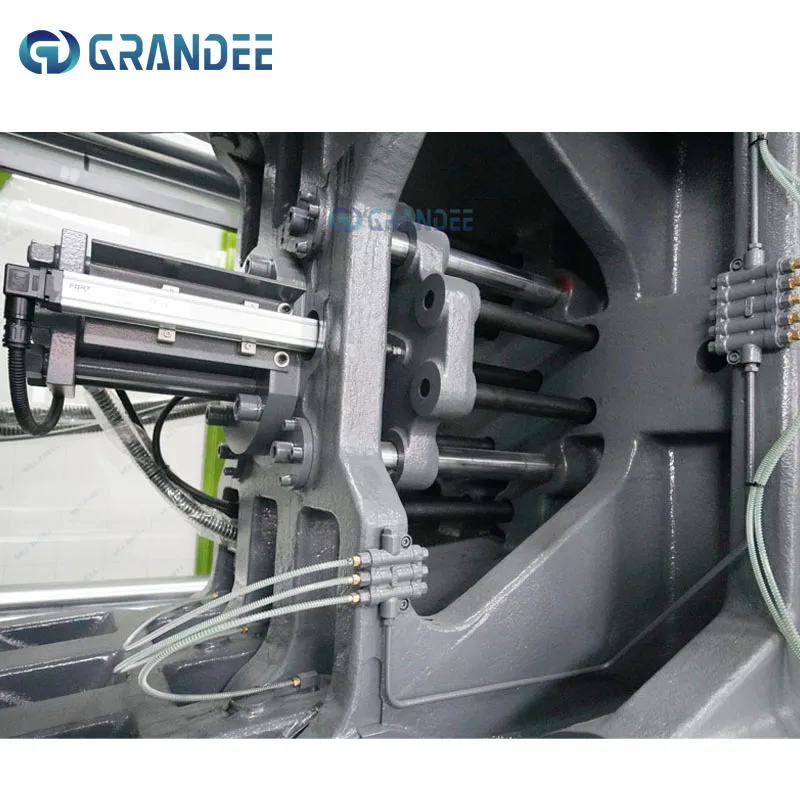

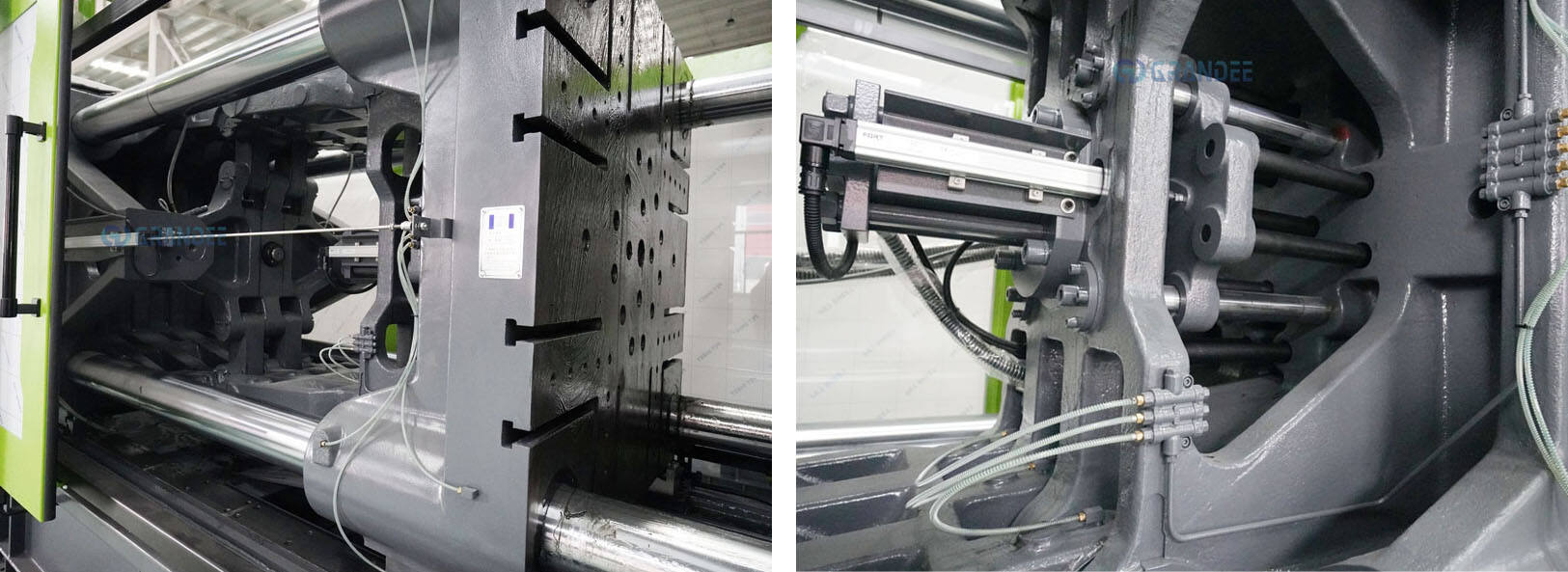

Klamps enhet:

5-punkts dobbelt toggle fastsystem av modulær optimeringsprogramvare for design. Sterk festing med rask og stabil, for å møte strenge festingsbetingelser. Formhøydejustering ved hjelp av hydraulisk drevet gear system med raskt og stabilt. Automatisk formhøydejustering etter innstillingen av festekraft, valgfri

Injeksjonenhet:

Balansert dobbelt injeksjonsylinder teknologi gjør at skrua har jevnt fordelt kraft under rask injeksjon, fem stjerner Hydraulisk motor med stor dreiemoment. Sikrer den utmerkede plastformingsbetingelsen. Forsker og utvikler ulike skruer etter forskjellige injeksjonsbetingelser, egnet for den gradvisne kravene og forbedrer betydelig injeksjonskvaliteten

Styringsenhet

Importert datamaskin spesielt for Injeksjonsmaskin med flere funksjoner og nøyaktig kontrollbehandling. Verdenskjente elektriske komponenter og høykvalitets kretsapparat med stabilt og pålitelig kjøring

Nei |

Navn |

Merkelapp/Materiale |

Opprinnelse |

1 |

Skruer/barel |

Ouwei/Fuyi/Tongda, 38CrMoAL |

Kina |

2 |

Tre skisser og injeksjonshode, andre plate |

QT500 |

Kina |

3 |

Servomotor |

Synmot |

Kina |

5 |

Hydraulisk motor |

Delson |

Italia |

6 |

Stroke Switch |

Honeywell/OMRON/Panasonic |

USA/Japn |

7 |

Luftskrua |

SCHNEIDER/LG |

Frankrike/Korea |

8 |

AC-kontaktor |

Schneider |

Frankrike |

9 |

Varmerelé |

Schneider |

Frankrike |

10 |

Styringsenhhet |

TECHMATION |

Taiwan, Kina |

11 |

Elektronisk linjal |

Jiesheng |

USA |

12 |

Pump |

Oufeite |

Kina |

13 |

Solenoidventilen |

YUKEN |

Japan |

14 |

Oljedampe/dusteslutt |

VALQUA/HALLITE |

Japan/UK |

15 |

KDAS bæringsring |

HALLITE |

Storbritannia |

16 |

Servostyring |

Mengde |

Kina |

En fase eller To fasers R.O. Vannbehandlingsanlegg

Råvannstank → Råvannspumpe → Kviskersandfilter → Aktivt karbonfilter → 5 Mikronfilter → 1 Mikronfilter → Høytrykkspumpe → Førstegradsmotstand Osmoseapparat → Mellemtanks → Forsterkningsspumpe → (Andregradshøytrykkspumpe → Andregradsmotstand Osmoseapparat) → Ozonblanding → Rent vannspumpe → Rent vatntank → Ekstern Forsyningsspumpe → Titanrørfilter → Ekstern Forsyning → Til Fyllingsmaskin

Automatisk OPP BOPP varmelim etikettmaskin

Automatisk BOPP-etikettmaskin er velegnet for ulike typer beholder- og etikettmateriale. Etikettkostnaden er relativt lav, og den kan tilfredsstille kravene fra brukere med mange forskjellige typer beholdere. Dette er en av de mest økonomiske modellene for massaproduksjon og integrert drift. Maskinen har brukt et omfattende modulær designkonsept for å gjøre det enkelt og greit for brukere å bytte ut flaskehoder. Uansett om det handler om å bytte ut stjernehjulet, veiledningsplaten eller manuell hastighetsjustering mot automatisk hastighetskontroll, som å bytte ut etikett krever bare at du endrer PLC-programmet, og produktfilosofien som sier at maskinen er laget for brukere og tenkt på brukerne, er synlig overalt.

Automatisk PVC PE Slip Shrink Etikettmaskin

Denne fullstendig automatiske armemerkemaskinen er egnet for ulike typer flasker, som runde flasker, firkantede flasker, ovalte flasker osv. Denne maskinen kan automatisk levere og klippe film, og den kan plassere armemerker nøyaktig, noe som sparet mye arbeid og forbedrer arbeids-effektiviteten. Maskinen kan brukes bredt til drikkeflasker, kosmetikkflasker, shampoflasker osv.

Driftsprinsipp for pakkeautomat

Den enkeltstykkede filmoppakningsmaskinen bygger på varmekontraksjonsegenskapene til oppakningsfilmen. Den bruker fotoelektriske skruesensorer for å oppdage online. De samlede signalene kontrolleres og behandles av PLC (programmerbar kontroller) programmer. En transportbånd brukes for kontinuerlig flaskelevering, flaske-separasjon, og trykk. Hele prosessen utføres av mekanismer som flaskeplassering, flaskeputting, kontinuerlig støttestang og flaske, enkeltfilmoppakning, filmhenting og formering, varmingskanalforstellet og kjøling og formgiving

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM