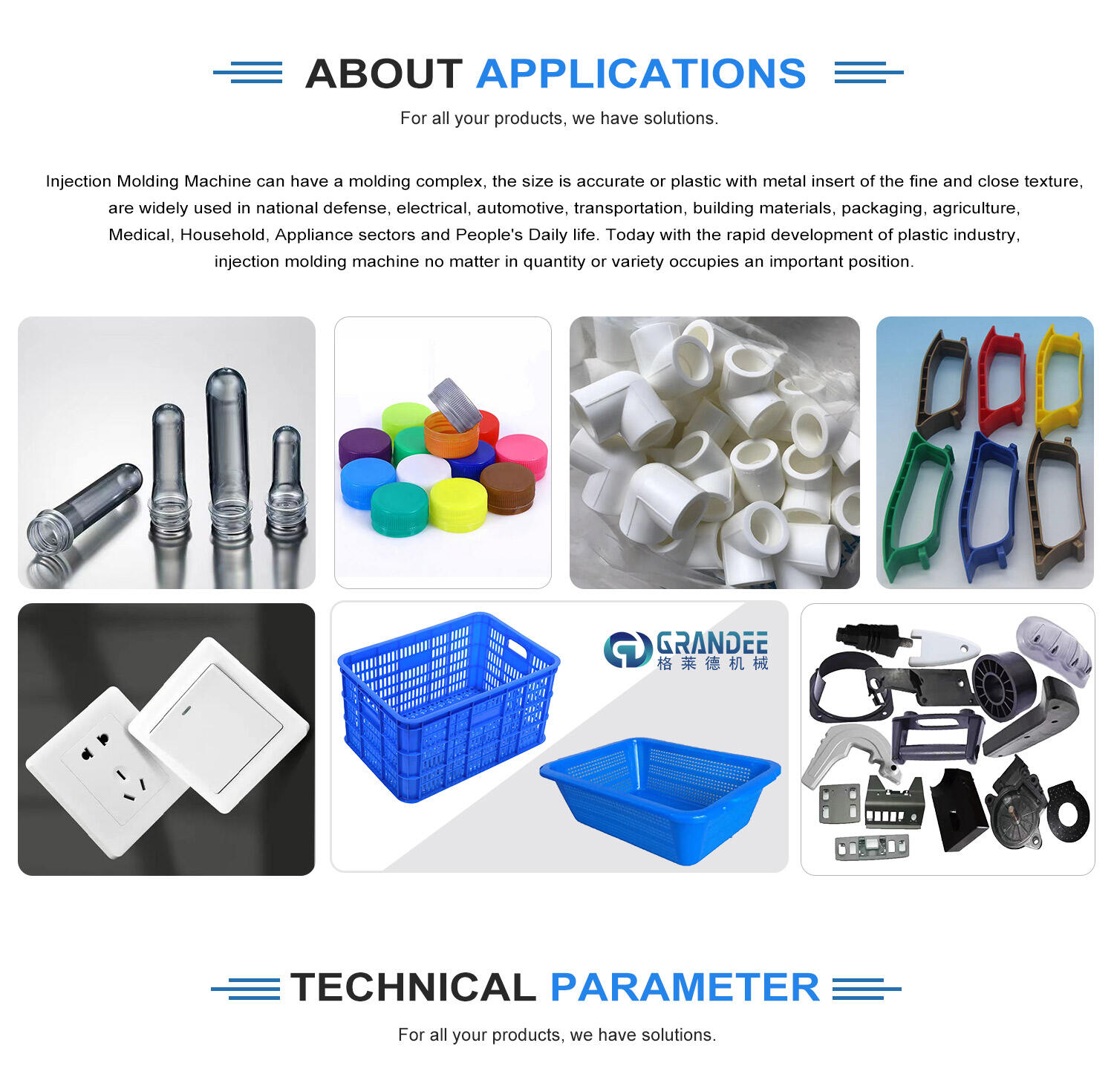

GRANDEE MACHINE laudatur dum introducit Machinam Formandi per Injectionem Bulbi Dripper Hydraulica Automatica Altae Velocitatis in Mensa. Haec machina innovativa est ad praecisionem et exactitudinem in industria manufactura plasticorum descripta. Est etiam sophistica et facilis ad usum, eam faciens optima optione tam pro professionistis quam pro principiantibus.

Machina Plasticam Faciens cum Systēmate Hydraulico Automātico Alte Velocitatis pro Bulbis Gutturis Injectionis Formae, praebet systēma hydraulicum validum, quod eam efficere potest partes plasticas optimae qualitatis. Celeritas eius est incomparabilis cum aliīs machinis similibus in mercātu. Hoc facit eam optima ad productionem massicam partium plasticarum, quae sunt in usu latōrum industriae, ut sunt automobilium, electronicarum et rebus domesticis.

Machina est plene automātica, quod significat eam exigere minimum interventionis humānae, celerem et efficientem reddens processum fabricationis. Comparāta cum methodis traditionalibus fabricationis, sicut formatura injectionis, huius machinae characteristicas automāticās faciunt eam excellentem optionem ad minuendam tempus productionis et ad minimizandum spilium materialis.

Firmitas et stabilitas sunt vitales factores in qualibet operatione fabricationis, et Machina Hydraulica Automatica Alta Velocitas pro Injectione Formarum Plasticarum cum Stilus Guttur Desktop est ad utrumque praestandum constructa. Ex materialibus optimi qualitatis confecta est, quae longam vitam eius certiores faciunt, et robustus eius cadaver excellens fundamentum operationi machinae praebet, productionem maximam garantians.

Machina est usor amica, quod eam facilem operationem reddit etiam his, qui novi sunt in industria fabricationis plasticarum. Cum instructionibus claris et facile sequendis venit, quae usores iuvant eam sine intermissione operare. Tabula controlis machinae ad simplificandam operationem fabricationis descripta est, et designum ergonomicum eius fatigam operatoris minuit, ita ut efficientia maxima per totum processum productionis conservetur.

Machina Hydraulica Automatica Alta Velocitatis pro Molding Plasticorum in Descripto, cum Functio Injectionis Globi Stillantis, est machina versatile quae potest producere latam varietatem partium plasticarum per varios processus formandi. Machina recipit varias species materiae primae, inter eas ABS, PC, PVC et PP et alias. Haec facultas facit eam investmentum eximium cuiusvis negotii volentis ingredi in industriam fabricandi plasticorum.

GRANDEE MACHINA est sita in Civitate Zhangjiagang, iuxta Shanghai in China. Sumus periti in campo machinarum imbuendarum liquidorum in orbe terrarum. Plusquam 10,000 metra quadrata officinae standard habemus, praebentes clientibus varietatem productuum evolutionis, ingeniique designii, consultii, servitiorum technicorum et aliorum integratorum solutionum EPC.

Proprietates Machinae:

Machina ad formandum per injectionem communiter constat ex systemate injectionis, systemate prehensionis, systemate hydraulico tractus, systemate electrico controlis, systemate lubricationis, systemate calefactionis et refrigerationis, systemate securitatis et aliorum componentium. Principium operationis machinae ad formandum per injectionem est simile syringae injectionis; per vim rotam (aut pistillum) bene plasticatum fusum (id est, in statum viscosum) bonum plasticum injectatur in clausam cavitas formae ut articuli formati post coagulationem obtineantur. Formatio per injectionem est processus cyclicus, cum quisque cyclo includente: quantificando alimenta - plastificando materiam sub pressione - injectione - implendo formam - refrigerando - aperiendo formam et colligendo producta. Tolle partes plasticas et iterum intra proximum cyclo operationis.

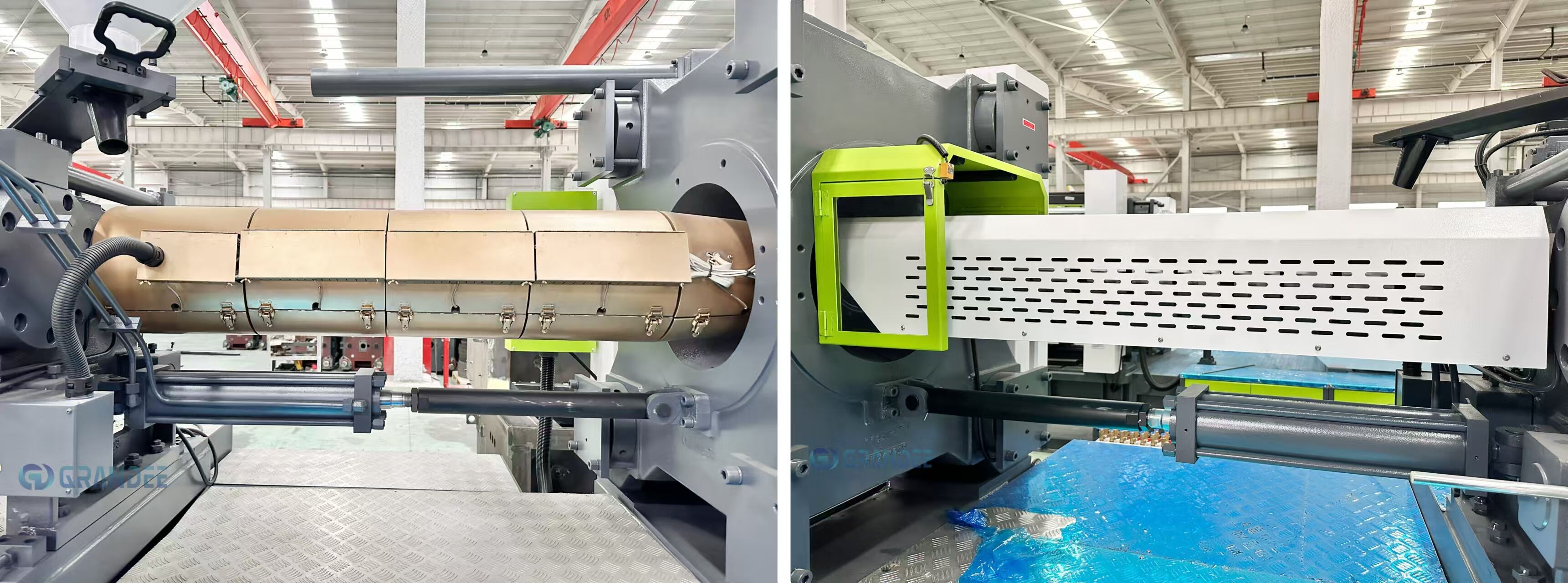

Circulus calefactionis infrarubri nanometrici:

Circulus calefactionis infrarubri nanometrici habet meliorem effectum isolationis, parvam amissionem caloris, citius calefaciens, citius praebens alimenta. Super hac basi, additur rostrum hydraulicum ut praeveniat materiam fluere extra.

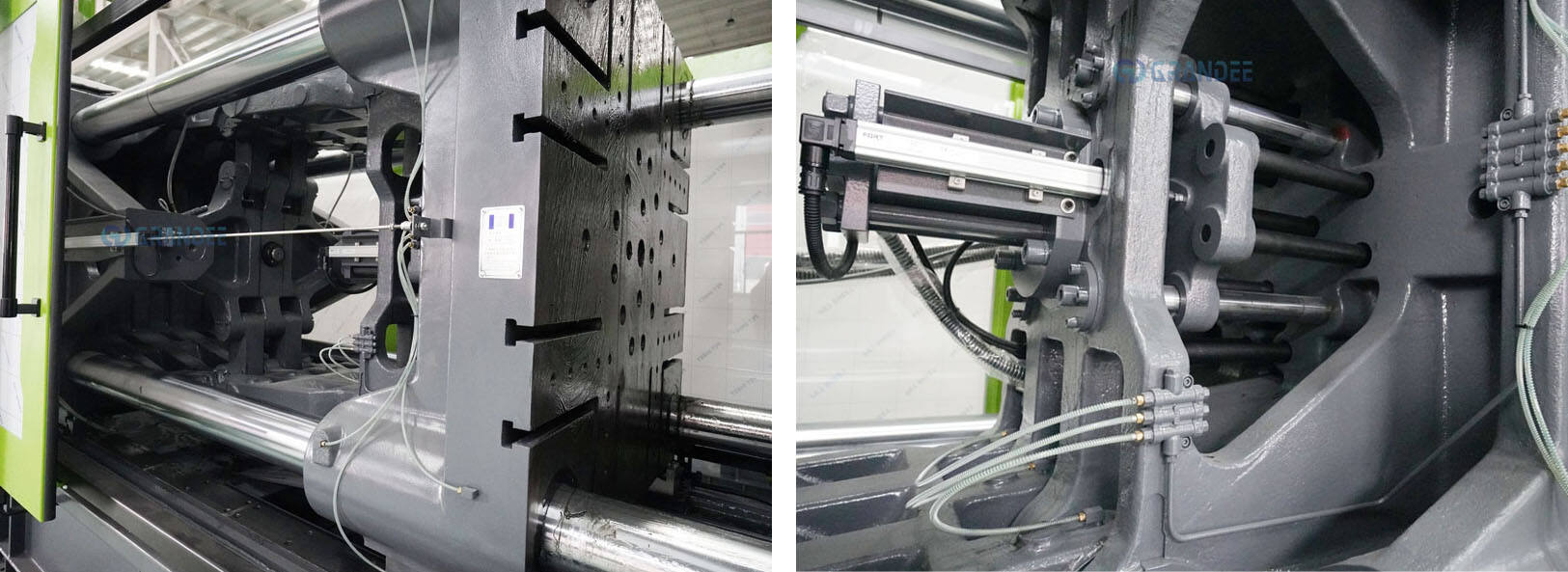

Unitas Prehensionis:

systema claudendi gemellum cum 5 punctis per software optimisationem modularem designatum. Claudendi fortitudo cum velocitate et stabilitate, ut conditionibus claudendi strictis satisfaciat. Ajustamentum altitudinis formae per systemam rotam hydraulice motam cum velocitate et stabilitate. Ajustamentum automaticum altitudinis formae secundum vires claudendi fixas optionale.

Unitas Injectionis:

Technologia cylindri injectionis duplis aequaliter distribuit vim super scrobem durante injectione celeri. Motor hydraulicus quinque stellis cum magnis momentis. Confirmat excellentes condiciones formandi plasticum. Investigatio et inventio diversarum scroborum secundum varias condiciones injectionis, apta propetuis demandis et maxime meliorat qualitatem injectionis.

CONTROL UNIT

Computator importatus specialiter pro Machina Formandi Injectionem cum multis functionibus et controllo precise processu. Componentes electrice mundiales famosae et hardware circuitus altae qualitatis cum operatione stabili et fida.

NON |

Nomen |

Marca \/ Materia |

Origin |

1 |

Fistula/barra |

Ouwei/Fuyi/Tongda, 38CrMoAL |

Sina |

2 |

Tres formae et caput iniectionis, secunda tabula |

QT500 |

Sina |

3 |

Motor servo |

Synmot |

Sina |

5 |

Hydraulica motoris |

Delson |

Italia |

6 |

Commutatio Gladii |

Honeywell\/OMRON\/Panasonic |

USA\/Japonia |

7 |

Air Switch |

SCHNEIDER\/LG |

Gallia-Corea |

8 |

Contactus AC |

SCHNEIDER |

Gallia |

9 |

Relay thermale |

SCHNEIDER |

Gallia |

10 |

Controller |

TECHMATION |

Taiwan, China |

11 |

Regula electronica |

Jiesheng |

USA |

12 |

PUMP |

Oufeite |

Sina |

13 |

Valva electromagnetica |

YUKEN |

Iaponia |

14 |

Sigillum olei/sigillum pulveris |

VALQUA/HALLITE |

Iaponia/ Britannia |

15 |

Anulus portans KDAS |

HALLITE |

Britannia |

16 |

Rector servus |

Mensura |

Sina |

Unum stadium vel Secundum stadium S.R. Systema tractandi aquam

Frons Aquae→ Frons Aquae Pompum→ Filtrum Arenae Quartzitae→ Filtrum Carbonis Activati→ Filtrum 5 Micron→ Filtrum 1 Micron→ Pompum Altæ Pressionis→ Dispositivum Primarium Osmosi Inversæ→ Intermedium Aquæ Vas→ Pompum Incrementi→ (Secundarium Pompum Altæ Pressionis→ Secundarium Dispositivum Osmosi Inversæ) → Mixtura Ozonis→ Pompum Puræ Aquæ→ Vas Puræ Aquæ→ Pompum Externum→ Tubus Filtrationis Titanii→ Externus Supply→ Ad Machinam Impletionis

Automata OPP BOPP calefaciens glutinans machina

Machina etichettatrice BOPP automatica est latae copiae idonea pro diversis materialibus recipientium et etichettarum. Costus uniuscuiusque etichettae est comparate inferior, quod potest satisfacere requisitis eorum usorium qui habent varios generes vasorum. Est una ex economiis maximis modellis ad faciendum productionem massicam et operationem integratam. Instrumentum usitavit conceptum designatus modularization in magna parte ut faciat facile et simpliciter pro usoribus commutare vasa. Sive a commutatione rotae stellae, tabulae ductricis sive adjustmente velocitatis manualis ad controllem velocitatis automaticam, veluti commutatio etichettae tantum requirit commutationem programmatum PLC, conceptus productivus quod instrumentum est usoribus et consideratum pro usoribus apparet ubique.

Machina Automatica pro Etichettis PVC PE Manicottis Contractionis

Haec machina completim automatica ad insigne brachiale apta est pro variis generibus phialarum, sicut phialae rotundae, quadratae, ovalis et cetera. Haec machina potest automate pelliculam praebere et incidere, et insignia accurate imponere, magna cum economia operis et incremento efficientiae operis. Machina hac potest late adhiberi pro phialis potus, phialis cosmetici, phialis shampoo et cetera.

Principium Operationis Machinae Imbutionis

Machina involucratoria unius partis pelliculae fundatur in characteristicis caloris contractionis pelliculae involutoriae. Ea photoelectricos commutatores sensorem adhibet ad online detectandum. Collecta signa sunt controlleta et processa per programmas PLC (programmatoris programmabilis). Taenia transportatrix adhibetur pro continua phiala praebendo, separando phialas, et totus processus per mecanismos tales ut pressura phiala, ponendo phialam, continua virga impellens et phiala, singula involventes pellicula, eligendo et formando pelliculam, canalem caloris contrahendo et frigore formando.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM