GRANDEE MACHINE praebet novissimam suam Velocem Machinam Injectionis Plastici pro industria cistarum fructuum et holusculorum. Haec machina est descripta ut praestet productionem altissimae qualitatis et efficientiae cistarum.

Machina est aedificata cum structura perdurabili et robusta, quae certificat eius performance diuturnam. Praedita est cum characteristicis recentibus, quae faciunt eam capax producendi cistas variorum magnitudinum et formarum cum velocitate et exactitudine. Hoc facit eam optima optione pro productione in scala magna.

Praeparatum utitur systemate hydraulicum, ut praebat lenem et constantem motum, certificando quod productum finis respondeat summam normarum qualitatis. Praeparatur cum systemate celeris controlis quod utitur recentissimis technologiis ad controlandum et monitum singulos gradus processus productionis. Hoc systema certificat quod productum finis sit summae qualitatis et quod productio sit efficax et effectiva.

Praeparatum formandi operatur utendo systemate plene automato, quod certificat quod processus productivus sit efficax, securus, et frugalis. Praeparatum continet interfaciem usor-amicae quae permitit operatoribus facile controlare et monitum processum productionis. Haec interfacies permittit facilem et velociorem dispositionem, faciendo id simplex ut machinam adjustes ad producendum cistulae diversarum formarum et magnitudinum.

Machina formandi etiam praedita est varietate characterum securitatis quae certam faciunt tutelam operatoris et machinae. Hi characteres comprehendunt buttonos stop emergentium, ianuas securitatis, et sensus automaticos qui detectant omnes abnormitates in productione.

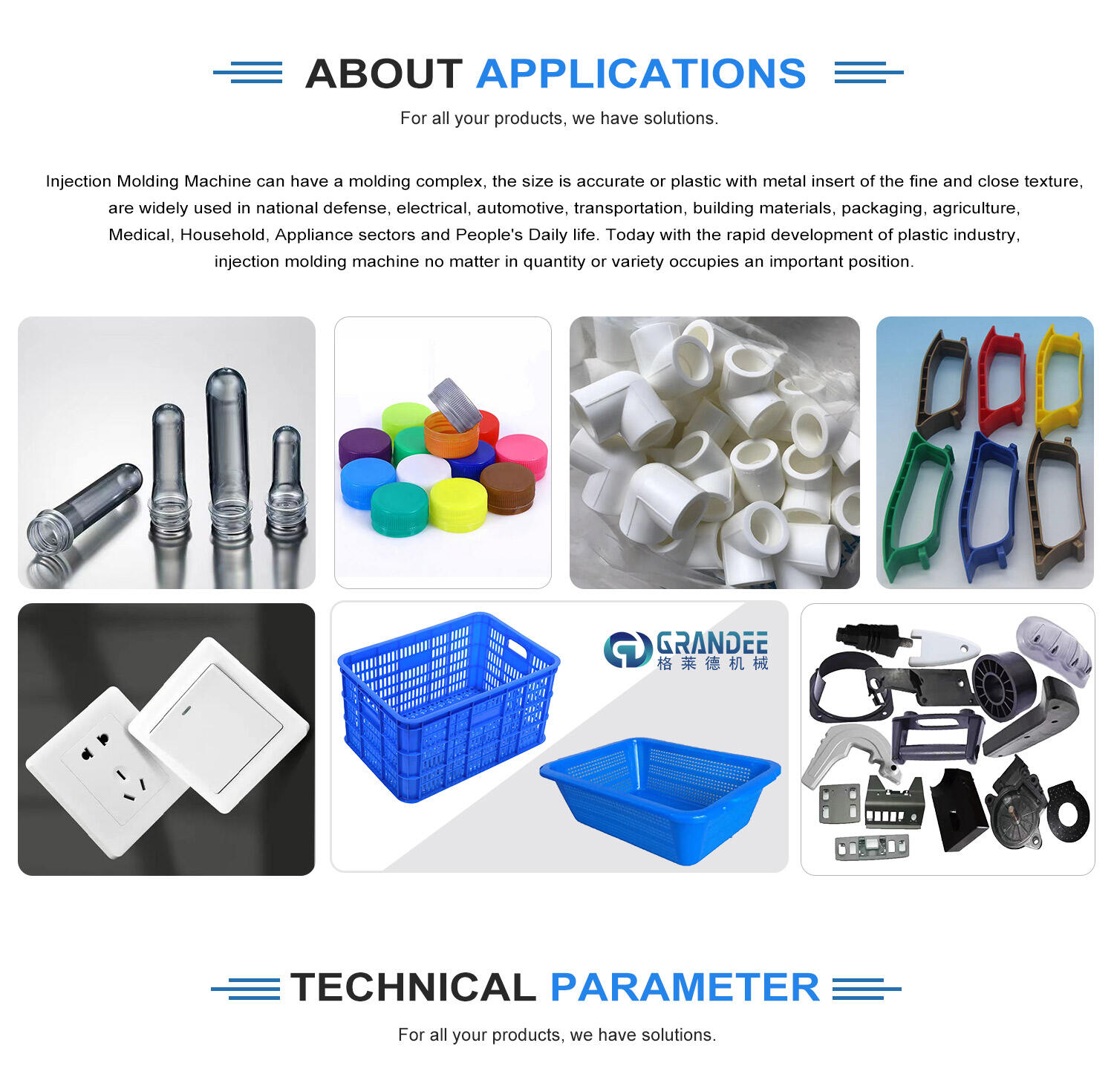

GRANDEE MACHINE nota est propter producenda fida et alta qualitas machinamenta quae sunt descripta ad satisfaciendum exigenti bus industriarum modernarum. Machina Injection Formandi Plastic velociter pro industria cestorum fructuum et olerum non est exceptio. GRANDEE MACHINE sperat hoc novum machinamentum mutare modum quo societates producunt cestos, certificantes quod possint producere producta altae qualitatis efficienter et economice.

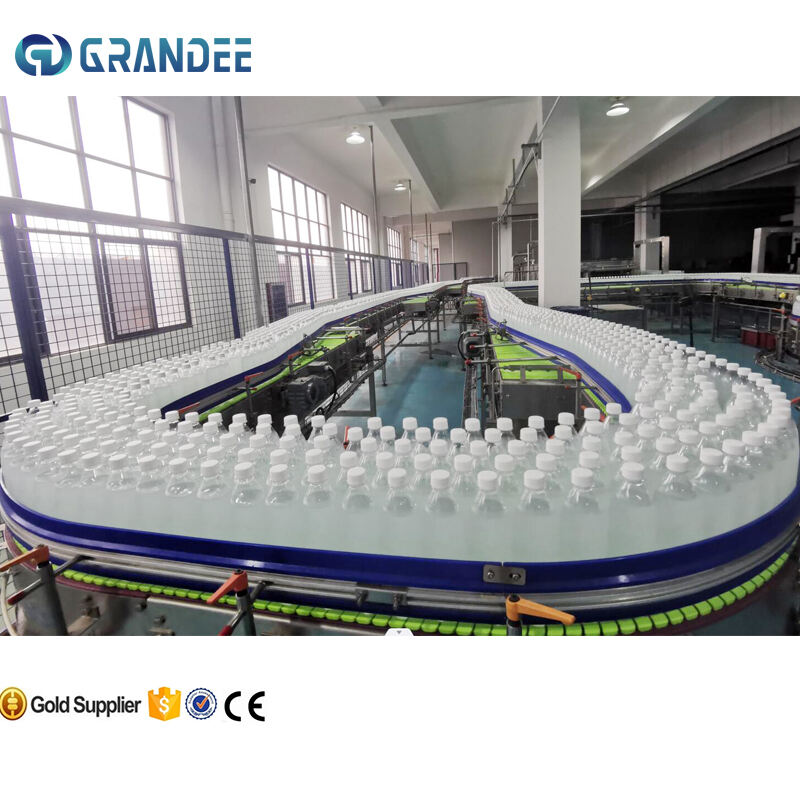

GRANDEE MACHINA est sita in Civitate Zhangjiagang, iuxta Shanghai in China. Sumus periti in campo machinarum imbuendarum liquidorum in orbe terrarum. Plusquam 10,000 metra quadrata officinae standard habemus, praebentes clientibus varietatem productuum evolutionis, ingeniique designii, consultii, servitiorum technicorum et aliorum integratorum solutionum EPC.

Proprietates Machinae:

Machina ad formandum per injectionem communiter constat ex systemate injectionis, systemate prehensionis, systemate hydraulico tractus, systemate electrico controlis, systemate lubricationis, systemate calefactionis et refrigerationis, systemate securitatis et aliorum componentium. Principium operationis machinae ad formandum per injectionem est simile syringae injectionis; per vim rotam (aut pistillum) bene plasticatum fusum (id est, in statum viscosum) bonum plasticum injectatur in clausam cavitas formae ut articuli formati post coagulationem obtineantur. Formatio per injectionem est processus cyclicus, cum quisque cyclo includente: quantificando alimenta - plastificando materiam sub pressione - injectione - implendo formam - refrigerando - aperiendo formam et colligendo producta. Tolle partes plasticas et iterum intra proximum cyclo operationis.

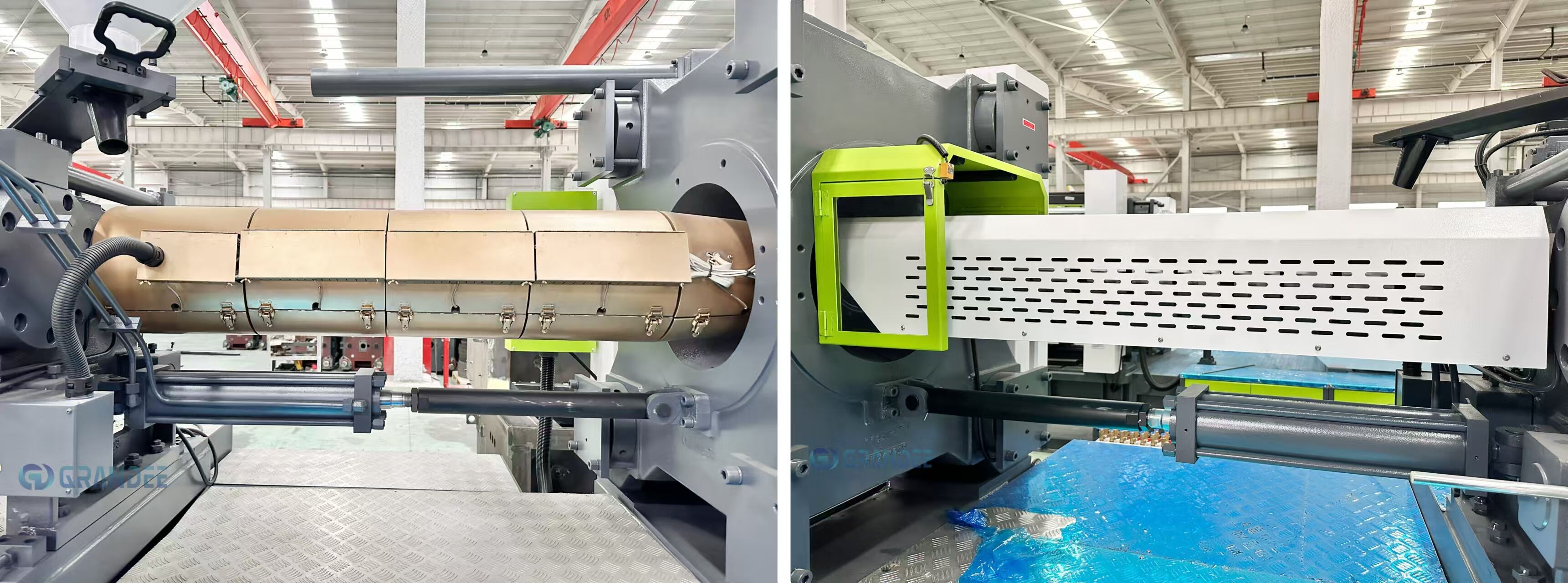

Circulus calefactionis infrarubri nanometrici:

Circulus calefactionis infrarubri nanometrici habet meliorem effectum isolationis, parvam amissionem caloris, citius calefaciens, citius praebens alimenta. Super hac basi, additur rostrum hydraulicum ut praeveniat materiam fluere extra.

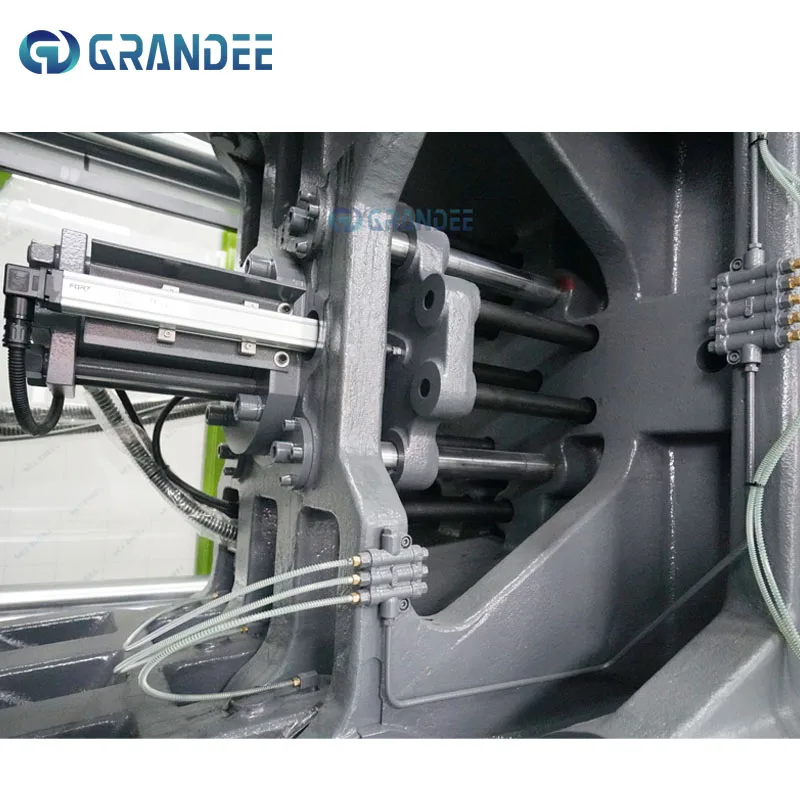

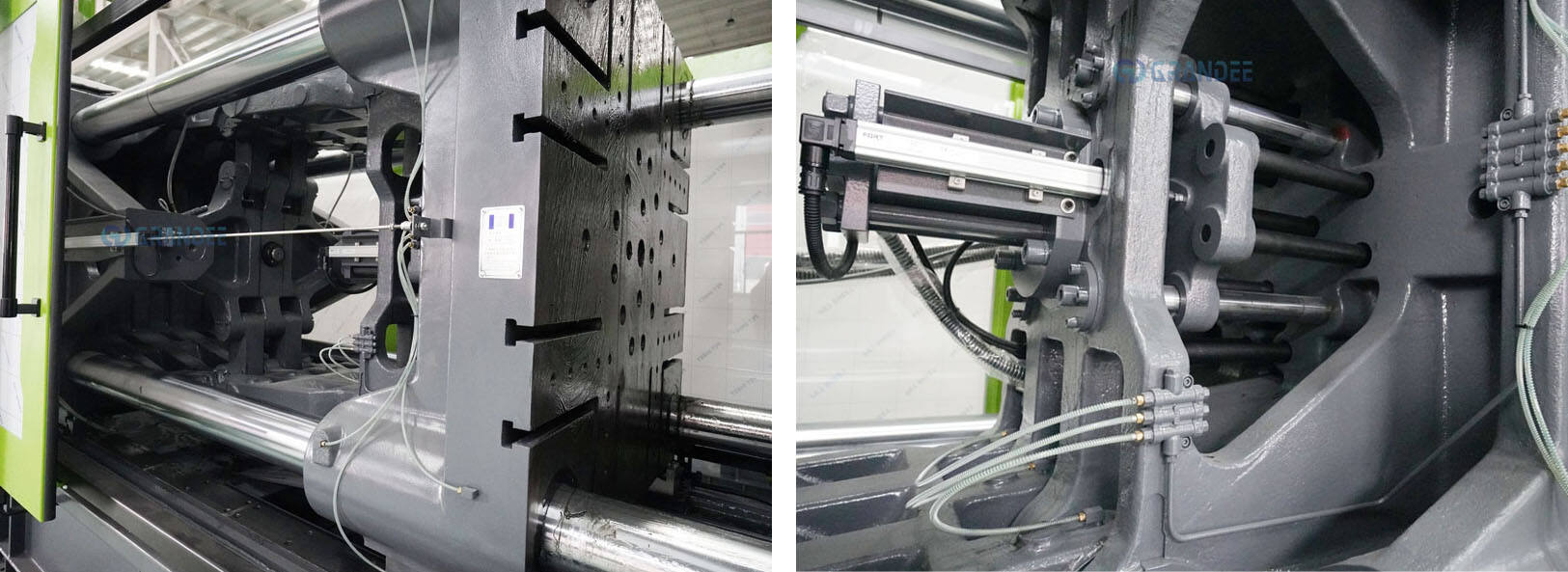

Unitas praehensionis:

systema claudendi gemellum cum 5 punctis per software optimisationem modularem designatum. Claudendi fortitudo cum velocitate et stabilitate, ut conditionibus claudendi strictis satisfaciat. Ajustamentum altitudinis formae per systemam rotam hydraulice motam cum velocitate et stabilitate. Ajustamentum automaticum altitudinis formae secundum vires claudendi fixas optionale.

Unitas Injectionis:

Technologia cylindri injectionis duplis aequaliter distribuit vim super scrobem durante injectione celeri. Motor hydraulicus quinque stellis cum magnis momentis. Confirmat excellentes condiciones formandi plasticum. Investigatio et inventio diversarum scroborum secundum varias condiciones injectionis, apta propetuis demandis et maxime meliorat qualitatem injectionis.

CONTROL UNIT

Computator importatus specialiter pro Machina Formandi Injectionem cum multis functionibus et controllo precise processu. Componentes electrice mundiales famosae et hardware circuitus altae qualitatis cum operatione stabili et fida.

NON |

Nomen |

Marca \/ Materia |

Origin |

1 |

Fistula/barra |

Ouwei/Fuyi/Tongda (38CrMoAL) |

Sina |

2 |

Tres formae et caput iniectionis, secunda tabula |

QT500 |

Sina |

3 |

Motor servo |

Synmot |

Sina |

5 |

Hydraulica motoris |

Delson |

Italia |

6 |

Commutatio Gladii |

Honeywell\/OMRON\/Panasonic |

USA\/Japonia |

7 |

Air Switch |

SCHNEIDER\/LG |

Gallia-Corea |

8 |

Contactus AC |

SCHNEIDER |

Gallia |

9 |

Relay thermale |

SCHNEIDER |

Gallia |

10 |

Controller |

TECHMATION |

Taiwan, China |

11 |

Regula electronica |

Jiesheng |

USA |

12 |

PUMP |

Oufeite |

Sina |

13 |

Valva electromagnetica |

YUKEN |

Iaponia |

14 |

Sigillum olei/sigillum pulveris |

VALQUA/HALLITE |

Iaponia/ Britannia |

15 |

Anulus portans KDAS |

HALLITE |

Britannia |

16 |

Rector servus |

Mensura |

Sina |

Unum stadium vel Secundum stadium S.R. Systema tractandi aquam

Frons Aquae→ Frons Aquae Pompum→ Filtrum Arenae Quartzitae→ Filtrum Carbonis Activati→ Filtrum 5 Micron→ Filtrum 1 Micron→ Pompum Altæ Pressionis→ Dispositivum Primarium Osmosi Inversæ→ Intermedium Aquæ Vas→ Pompum Incrementi→ (Secundarium Pompum Altæ Pressionis→ Secundarium Dispositivum Osmosi Inversæ) → Mixtura Ozonis→ Pompum Puræ Aquæ→ Vas Puræ Aquæ→ Pompum Externum→ Tubus Filtrationis Titanii→ Externus Supply→ Ad Machinam Impletionis

Automata OPP BOPP calefaciens glutinans machina

Machina etichettatrice BOPP automatica est latae copiae idonea pro diversis materialibus recipientium et etichettarum. Costus uniuscuiusque etichettae est comparate inferior, quod potest satisfacere requisitis eorum usorium qui habent varios generes vasorum. Est una ex economiis maximis modellis ad faciendum productionem massicam et operationem integratam. Instrumentum usitavit conceptum designatus modularization in magna parte ut faciat facile et simpliciter pro usoribus commutare vasa. Sive a commutatione rotae stellae, tabulae ductricis sive adjustmente velocitatis manualis ad controllem velocitatis automaticam, veluti commutatio etichettae tantum requirit commutationem programmatum PLC, conceptus productivus quod instrumentum est usoribus et consideratum pro usoribus apparet ubique.

Machina Automatica pro Etichettis PVC PE Manicottis Contractionis

Haec machina completim automatica ad insigne brachiale apta est pro variis generibus phialarum, sicut phialae rotundae, quadratae, ovalis et cetera. Haec machina potest automate pelliculam praebere et incidere, et insignia accurate imponere, magna cum economia operis et incremento efficientiae operis. Machina hac potest late adhiberi pro phialis potus, phialis cosmetici, phialis shampoo et cetera.

Principium Operationis Machinae Imbutionis

Machina unica pro pellicula involutoria basatur in characteristicis contractionis caloris pelliculae involutoriae. Utitur sensoribus commutatorum photoelectricorum ad detectandum online. Signa collecta controlantur et processantur per programmas PLC (programmabilis controller). Fita transportatoria utitur ad alimentationem continuiam buticularum, separationem buticularum et pressionem. Totus processus completur per mechanicas tales qualis buticuli, ponere buticulum, impellere continua virga et buticulum, involvere singulam pelliculam, eligere et formare pelliculam, canalem calefacientem contrahentem et refrigerationem et formam.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM