GRANDEE MACHINA est sita in Civitate Zhangjiagang, iuxta Shanghai in China. Sumus periti in campo machinarum imbuendarum liquidorum in orbe terrarum. Plusquam 10,000 metra quadrata officinae standard habemus, praebentes clientibus varietatem productuum evolutionis, ingeniique designii, consultii, servitiorum technicorum et aliorum integratorum solutionum EPC.

Machina Flati Phialarum Implendorum et Capparum Combiblock

1. Systema controlis progressivum Machina ad flatus butyrum rotatoria automatica alta velocitate CGX, quam nostra fabrica conficit, systemate controlis utitur, quod ex SIMATIC HMI interfacie humani cum machina, systemate controlis industrialis Siemens S7 seriei et systemate PLC atque relevantibus mechanismis detectionis et actuationis constat. Totum systema stabile, fidum et promptum est.

2. Systema protectionis securitatis machinae Omnis punctus torsionis et punctus clavis machinae praeditus est protectis torsionis, commutatoribus photoelectricis, commutatoribus itineris protectionis et aliis mensuris protectionis, ut securitatem operationis instrumenti conservet, vim operationis robotis vitet, ita vitam utilitatis machinae prolongando et onera conservationis accessoriis minuendo.

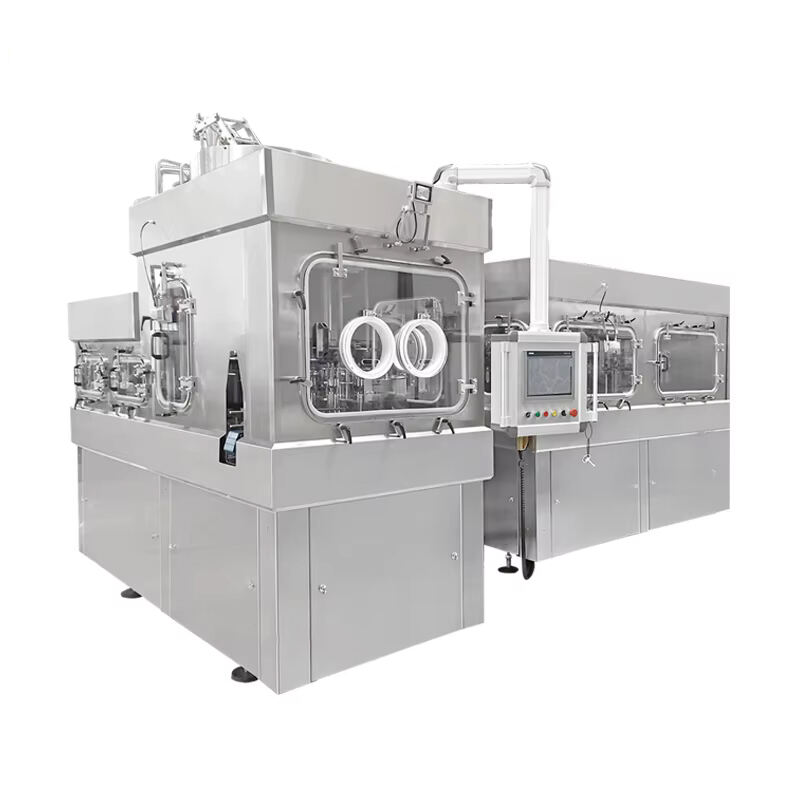

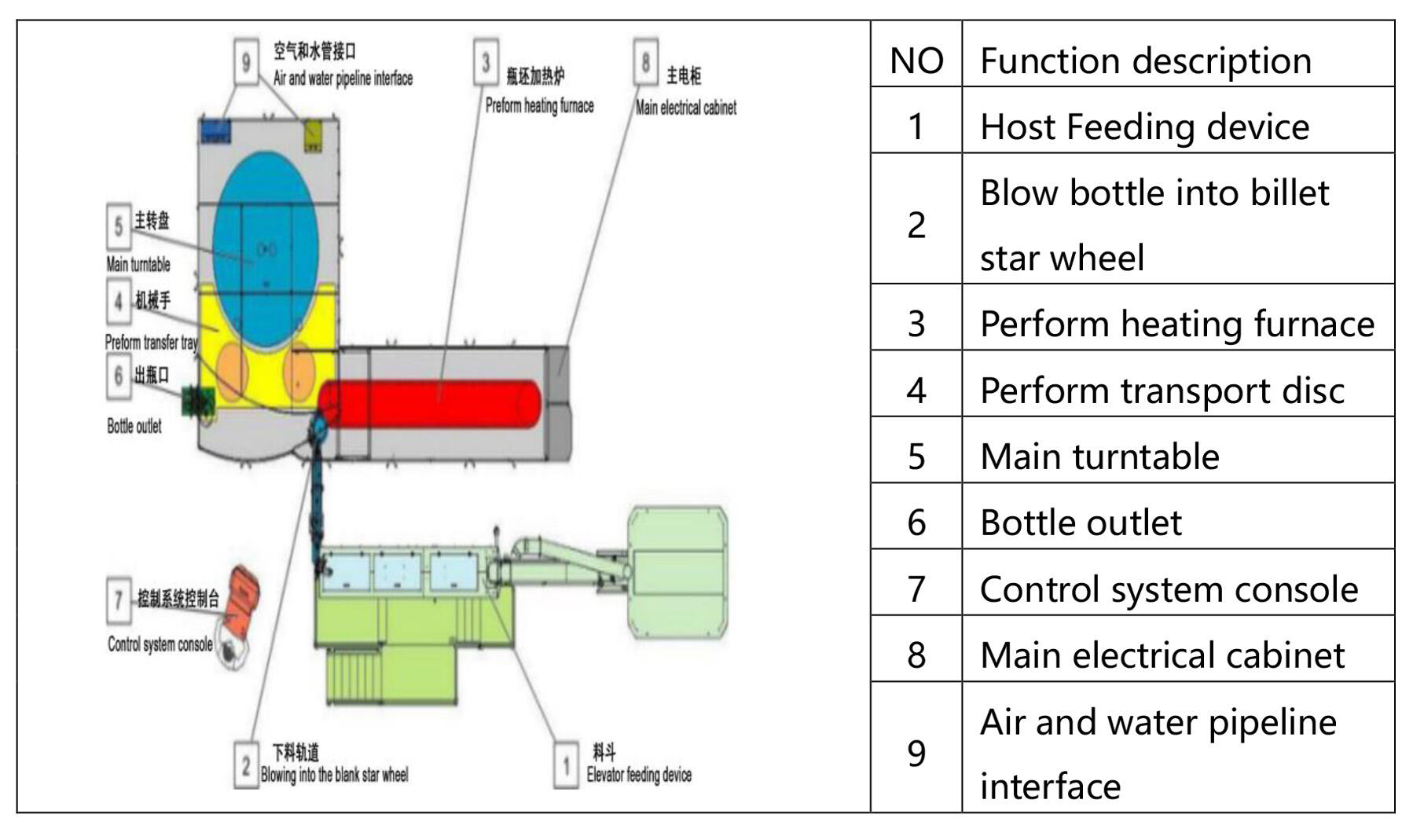

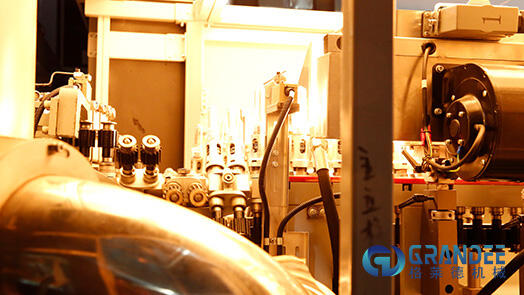

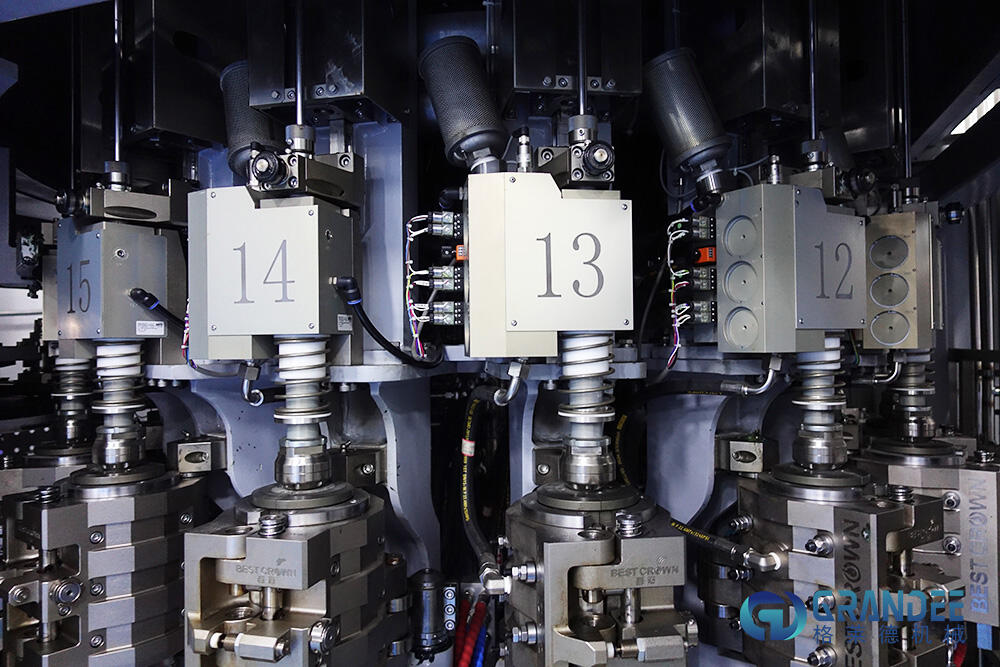

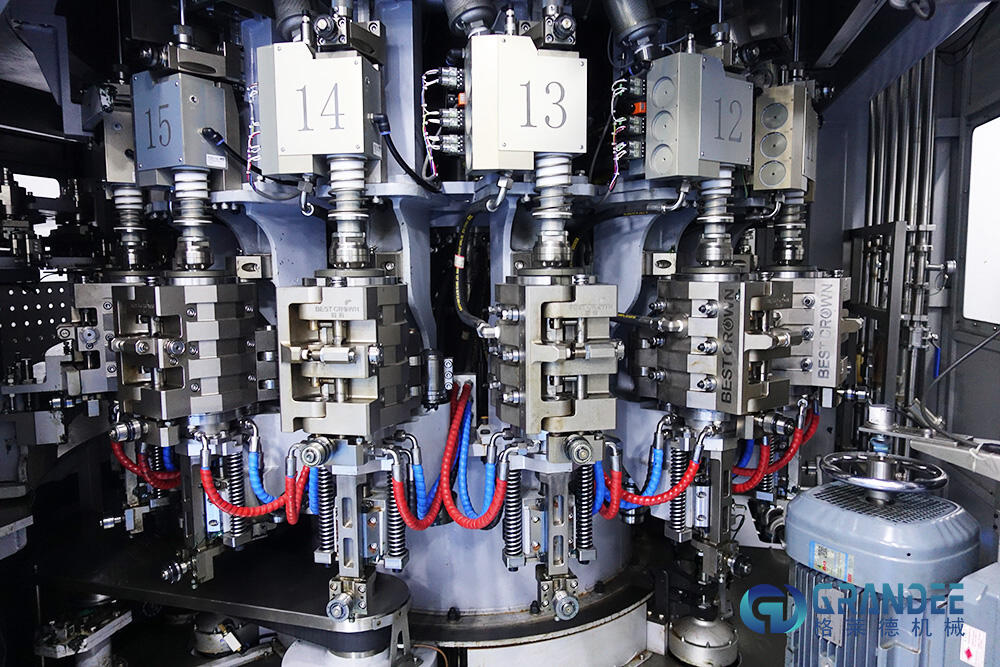

3. Species exterior machinae ad flatus butyrum in figura ostenditur. Machina rotatoria automatica ad sufflando est machina ad sufflando bidivi velocis, feliciter inventa a nostra societate ut absorbeat technologiam maximam in fabricando butylis praesentem in mundo hodie. Haec machina constat ex apparatu alimentario automatico, silo, mechanismo elevandi, tractu alimentario integro, fornace calefaciendo, machina principalis ad sufflando, systemate controlis electrici et systemate controlis pneumatici.

|

NON

|

Exemplum

|

Capacitas

|

Mensura Lagonis

|

|

1

|

8-24-8

|

12000BPH

|

500ml

|

|

2

|

8-32-8

|

15000BPH

|

500ml

|

|

3

|

8-40-10

|

16000BPH

|

500ml

|

|

4

|

12-42-10

|

18000BPH

|

500ml

|

|

5

|

16-40-15

|

24000BPH

|

500ml

|

|

6

|

20-60-18

|

36000BPH

|

500ml

|

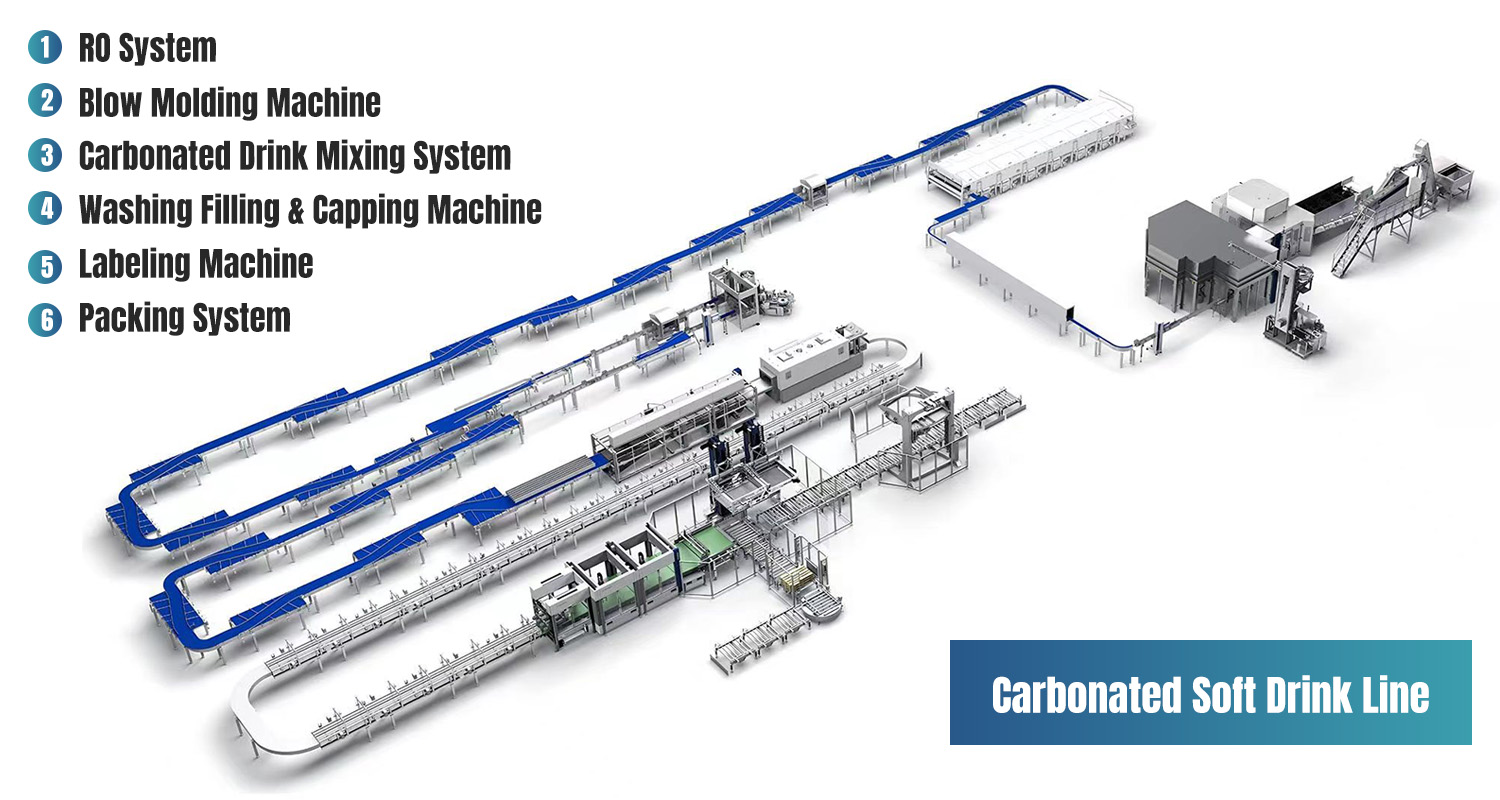

Diagramma Fluxus Processus Operantis

Pelagus Technical Parameter

|

Capita

|

|

Machina implendae: 24, cingulorum applicatio: 8

|

|

10Capacitas

|

|

12000BPH 600ml putescens

|

|

Applicabilis Typus Fiaculae

|

|

PET Recipaculum

|

|

Applicabilis Typus Fiaculae

|

Ambitus diametri butyri

|

D=50~97mm

|

|

|

Ambitus altitudinis butyri

|

H=150~310mm

|

|

Consumptio aeris compressi

|

|

0.8m3/min 0.7MPa/h

|

|

Aquae refrigerationem consummatio

|

|

3000L/H

|

|

Temperatura aquae refrigerantis

|

|

1-5℃

|

|

Voltage Laborans

|

|

380V, 50HZ

|

|

Tensio controlis DC

|

|

24V

|

|

Torque operis

|

|

0.6~2.8Nm Ajustabilis

|

|

Potentia

|

|

4.0kW

|

|

Dimensio L*W*H

|

|

2450x3100x3100mm

Subiectum est duci finali

|

|

Pondus

|

|

Circa 12T

|

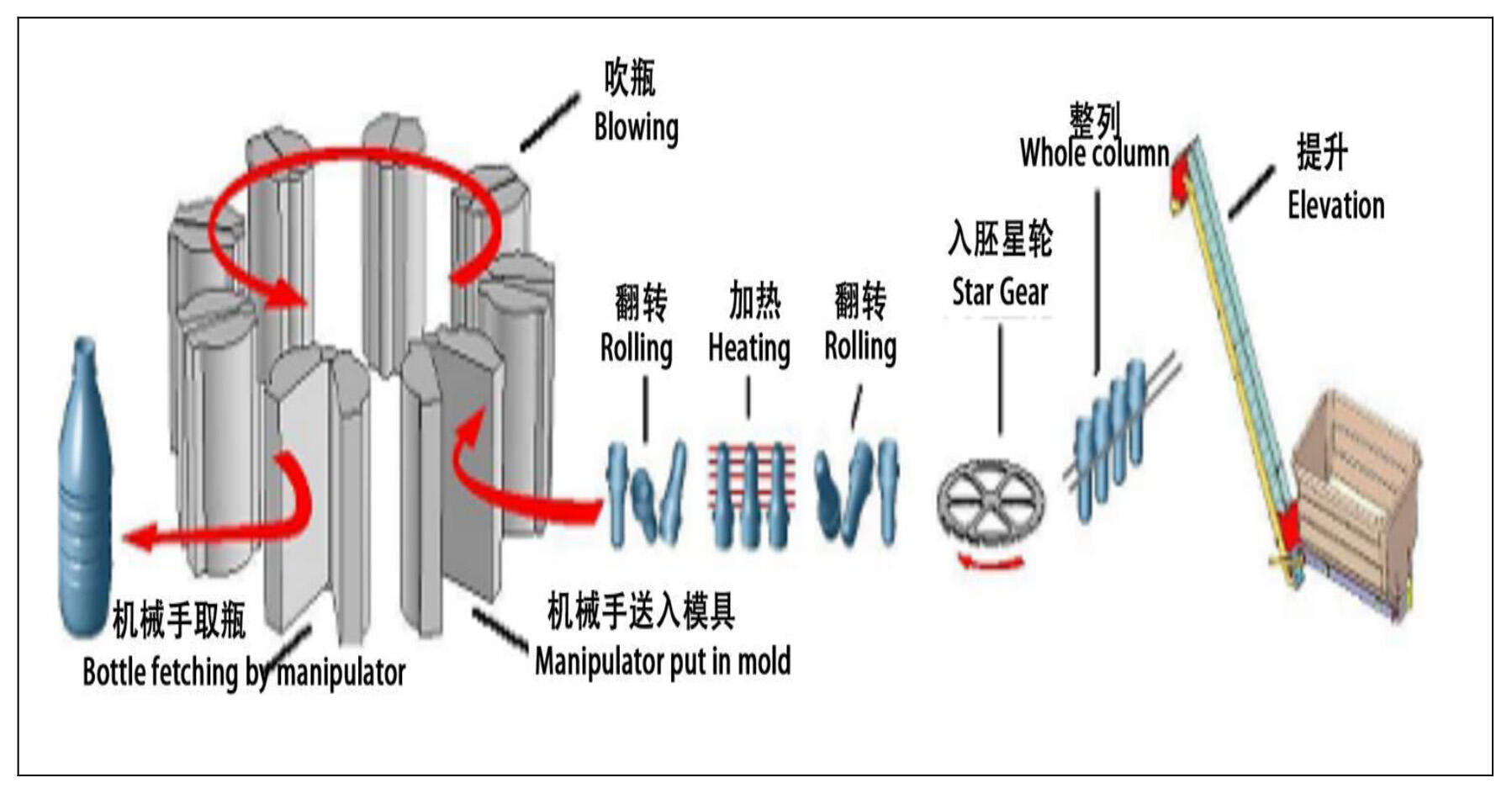

1. Praeforma introducendi et dissolvendi

Utitur matura methodo standardizata in toto orbe terrarum pro praestantia introductionis et ordinandi praeformarum, per quam praeformae pergerunt per elevatorem praeformarum et traducuntur ad dispositivum praeformarum. Intra dispositivum praeformarum, praeformae sunt automate dispositae et deferuntur duobus cylindris inclinatis eadem cum velocitate, et reliquiae capientur rota stellata et remittentur ad recipaculum praeformarum. Totus processus ordinandi praeformarum est plene automaticus et habet altam efficientiam sine praeformis exculptis.

Introducio ad machinam sufflando Partes principales, sicut cylindrus sigillarius insulae valvae sufflationis butyri, omnes importantur et personaliter conficiuntur a SEITZ. Sufflatio butyri applicat recuperationem gas altae pressionis ad necessitates gas bassae pressionis. Structura fornacis inversa economizat energiam per 15%. Sufflatio butyri habet detectionem pressionis et functionem reiectionis mali butyri. Status operationis systematis potest monitari remote. Uti formis foratis altius fortium, apparatus operatur efficienter et stabiliter. Orbita operationis apparatus est patentia, cum vibratione minima, sono parvo, et operatione stabili et fida.

Forma automatae machinae sufflando Forma est factor importantis qui adfectat processum PET flaschae soufflant, et forma formae poterit difficultatem processus adjustmentis diminuere vel augere. Exempli gratia, fortificatio, arcus zonis transitionis et calor dissipationis condicio in fundo habent impactum super processum adjustmentis et directe adfectant qualitatem flascae, ita recommendamus clientibus attendere ad novam et unicum productum packaging et pulchrum simul, considerare an electa flasca species possit satisfacere usus requisitionibus, optime est ut per nostros professionales designers revisetur. Quando forma customizatur, necessarium est praecipue materiam et installationem dimensionem definire. Productum capacitas altitudinis requisitiones faciunt.

Virtutes machinae impletionis et cappandi

1) Disacus rotans conficitur ex aere inoxydabili ANSI304 2) Magnus planus rotor, suavis et fidelis operatio 3) Impletio adoptat methodum impletionis per gravitatem. Specialis designatio foraminis valvae impletionis potest efficaciter evitare stillantiam. Simul, specialis designatio itineris fluxus valvae impletionis potest conservare parvam et stabilem columnam fluidi impletionis 4) Adoptatur cylindrus liquidus annularis, et nivelletur liquor per sensorem continualem et valvam regulandi fluxum 5) Valva impletionis instruitur calice lavandi, qui potest perficere integram cyclicalim lavationem valvae impletionis 6) Utitur capite claudendi cum torqui magnetico constante, et effectus claudendi est stabilis et fidelis 7) Installatur series commutatorum photoelectricorum in raila ductu capsulorum. Quando non est capsula in raila ductu capsulorum, machina cessabit automate currere, quod potest efficaciter evitare apparitionem capsulae sine bottulis 8) Praebetur commutator detegentis bottuli ingressus in machina claudendi, et cylindrus clausus capsulae coniugatae cum raila ductu capsulorum et tabula capsulae inter se controllat emissionem capsulae, conservans ut capsula sistatur quando non est bottulus et minuens damnum capsulae

Systema Unguentationis pro Traductione

Unguenta traducens catenam, apta ad usum in industria ciborum, aquae, potiones, cervisiae, condimenta et alia commercia unguationis catenae tabularum traductionis.

|

Nomen

|

Notam

|

Area

|

|

PLC

|

Siemens

|

Germania

|

|

Inverter

|

Siemens

|

Germania

|

|

Contactor

|

Siemens

|

Germania

|

|

Tactus screen

|

Siemens

|

Germania

|

|

Inverter

|

Siemens

|

Germania

|

|

Motor

|

ABB

|

SWISS

|

|

Partes pneumaticae

|

FESTO

|

Germania

|

|

Partes electricae

|

SCHNEIDER

|

Gallia

|

GRANDEE MACHINA

8000-10000bph Combiblock asepticum lac pasteurizatum ventilatio impletio apparatus est cappatura yogurt processus line – solutio optima est ad requisita casei processus et bottling

Facta cum praecisa ingeniaria et technologia progressiva ut certificetur effectus sit optimus. Praesentia ventus impletio combinata, et procedura cappatura certificatur productionem sit ordinata et velocior productionis costus

Facta pro praesens in creatione lactis, yogurt, et potiones saporatas. Est remedium ideale casei quod flores volunt systema efficientissimum et fidem. Productum monstrat quod cibus casearius tuus geritur hygienice et impletur ad exacta requisita impletionis ad cappationem

Factum cum pasteurizatione alta qualitatis quod certificat cibum casearium tuum esse tutum ad consumendum. Productum factum est ut calefaciat lac ad 72°C per 15 momenta antequam refrigeret ad temperaturam impletionis

Perficientissime et directe ad usum, haec linea butylandi creari potest pro simplici conservando, tempus inopinatum minuendo et efficientiam auctam. Systema elementa comprehendit quaedam que saepius possunt dissolvi ad lavandum et hygienam meliorem.

Instrumentorum valvulae implentur separatim ab sensoribus electronicis qui accurate et constanter implet. Praeterea habet cappam automatice, certificando ut omnis vas ad quantitatem rectam impleatur et penitus claudatur.

Venditur cum Interface Human-Machine (HMI) quae facit operationem mercimoni simplem et intuitivam. Tabula ostendit declarationes veras de mercedis operatione, inclusive eius pretii productionis et usus mercimoni, praebens operatoribus informationem tempore reali qua possunt uti ad optimam faciendum huius mercedis operationem.

Decide tentare nostram MACHINAM GRANDEE 8000-10000bph Combiblock asepticum pasteurizatum lac blowing apparatus quod implet cappat processus yogurt bottling linea hodie et habe differantiam

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM