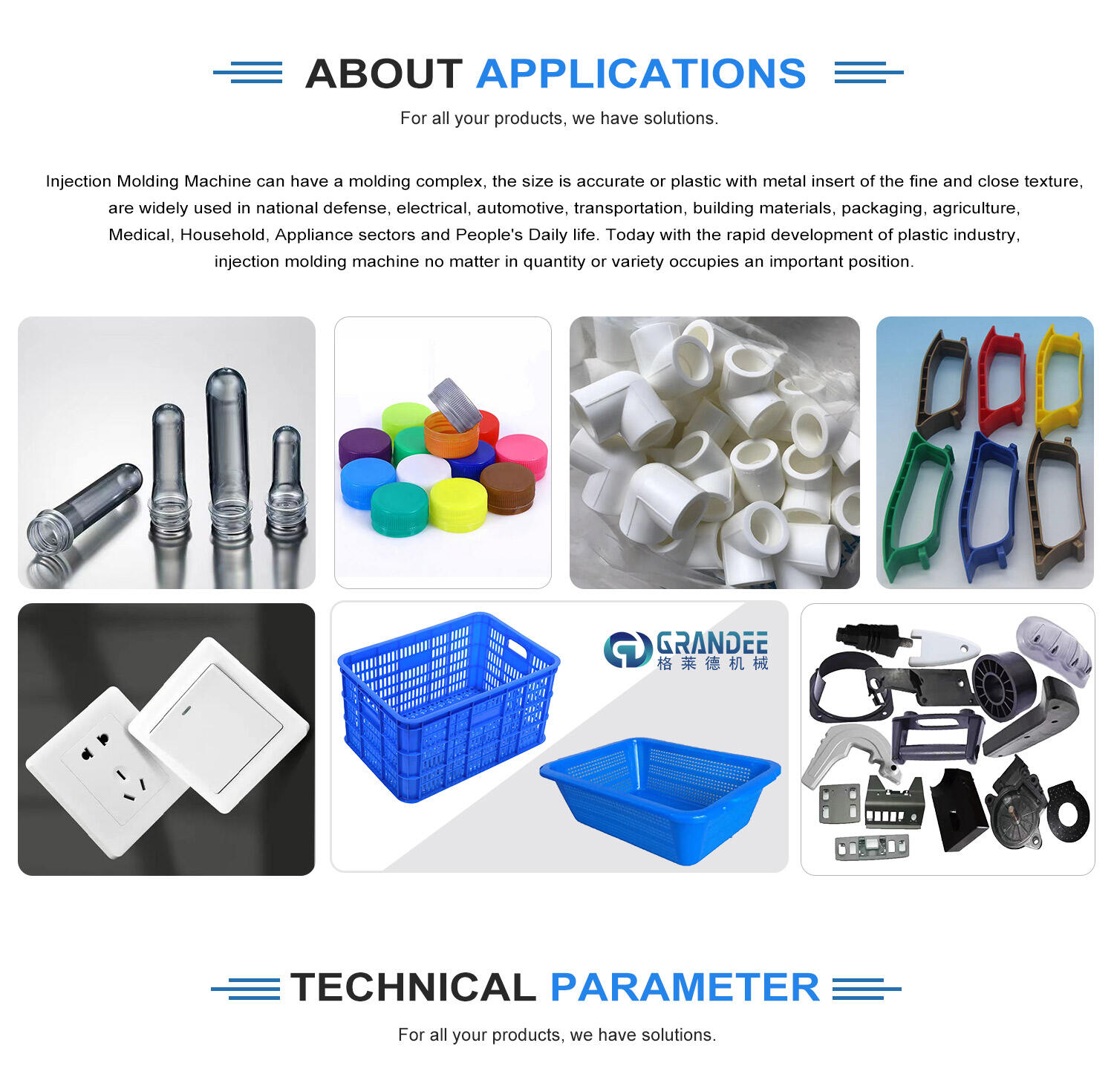

LA MASHIN GRANDEE fièr prezenre Mashin Modelaj Injeksyon Boul Dripe Rapide Automatik Hidraulik Dezyebo a. Machin inovatif sa desan pou presizyon ak eksaktid nan industri fè plastik. Li sofistike ak fasil pou sèvi an san mem, fè li yon bon chwa pou kenbe ak pofesyonèl.

Mashin fòs vitès lajanmatik hidraulik ki sèvi pou fabriker boul plastic sou tabye a te gen yon sistèm hidraulik puiissant, k ap fè l kapab pwalise pi bon kouto partrè yo. Vitès li pa gen konpare avè machin lot ki nan mache a. Sa a fè li idéal pou produksyon enmas nan partrè plastic ki sèvi nan plizyè zòn antre okipasyon, elektronik, ak objè domesik.

Mashin an tout krimatik, sa vle di li bezwen minimum interbasyon moun, sa ki fè pwosesis fabricasyon li vit e efisyan. Lè ou karege ak metòd tradisyonèl fabricasyon kòm modelaj injeksyon, karakteristik krimatik mashin an fè li yon chwa sanble pou diminye tan produksyon ak minimiz sya malrez.

Fiabilite e stabilite se faktè kritik nan tout proses manjman, ak machin Driper Bulb Injection Molding Hydraulic Automatic Vites Nan Bwò Dekstop a desann pou founi de. Li konstri ak materyo kalite ele ki asire lonjevite li, e pye li fi ofri yon baz ekslan pou operasyon machin la, garanti prodiksyon maksimal.

Machin an antilat pou itilizatè, ki fè li soti senp pa gen pwoblem mem pou yo ki nouvo nan industri fabriksyon plastik. Li vin ak instrkisyon klè e fasil pou siwi ki ede itilizatè yo operasyone l san entrap. Panè kont lou machin an desann pou simplifie proses fabriksyon an, ak dizèn ergonomik li redwi lezotaj operatè, asire efikasite maksimal nan tout proses prodiksyon.

Machin Moulaj Bul Driper Hidravlik Otomatik Vites Lèt sou Bèb Desko a se yon machin polyvalan ki ka pwodüi yon gren variété piyas partrè a travè dife moudaj diferan. Machin an aksepte divè tip matyè premye, antre l yo ABS, PC, PVC, ak PP, epi lòt. Sistèm sa a fè li yon investisman ekstravadjan pou tout biznis ki vle antre nan sèk lajan plastik.

GRANDEE MACHINE ap jwenn nan vil Zhangjiagang, pres nan Shangai Chine. Nou se ekspè nan domèn mashin pakaj lide nan mondan. Nou gen plis pase 10,000 met kare atèl standa, ki fèt pou bay klant yo yon variète devlopman pwodwi, desen jennik, konsiltasyon, sèvis teknik ak lòt solyisyon EPC integre

Karakteristik machin :

Mashin modelaj pa injeksyon sòtman konsète nan sistèm injeksyon, sistèm klejan, sistèm driva hidraulik, sistèm kontròl elektrik, sistèm liyann, sistèm chofe e refrezi, sistèm monitòj sekirite ak lòt komponent. Fonksyonman mashin modelaj pa injeksyon te simitè ak yon syring injeksyon, li fonksionnen pa bizon (o pa piston) pou pouse, fè plas ajoute nan etat fon (kak se, nan etat viskoz) nan yon kat mwa fèmen pou otenyen atik formè aprè kijan. Modelaj pa injeksyon se yon proses siklik, ak chak sikli gen anplis: dosaj aliman - plastizasyon dous - injeksyon dous - rempi a kat - refrezi - desklejan ak retire pwodwi. Retire piyas plasik la akòdonn anviwonman nan sik li yo.

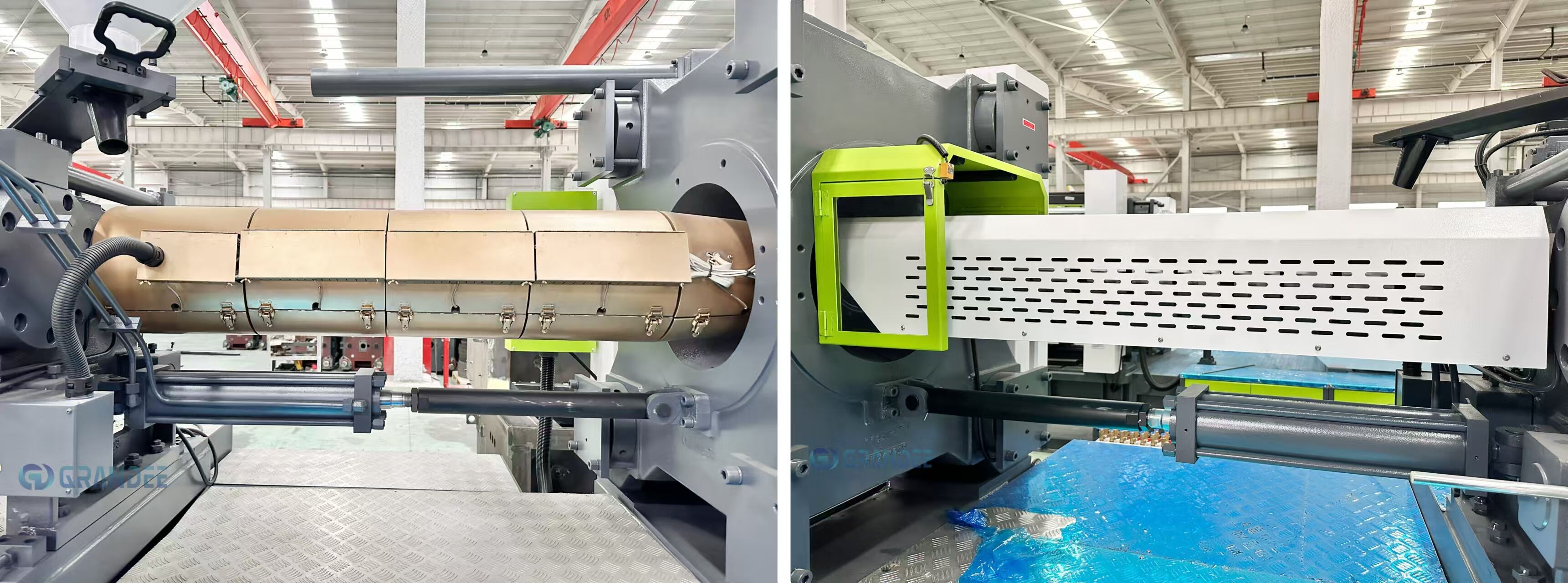

Bague chofe infrarouj nanometrik:

Bague chofe infrarouj nanometrik gen efè isolasyon pi byen, pèdi chalèf pi piti, chalèf pi vit, epi pi vit pou rantre nan materya. Nan baze sa a, yon bec hidraulik te ajoute pou empeche materyo sorti.

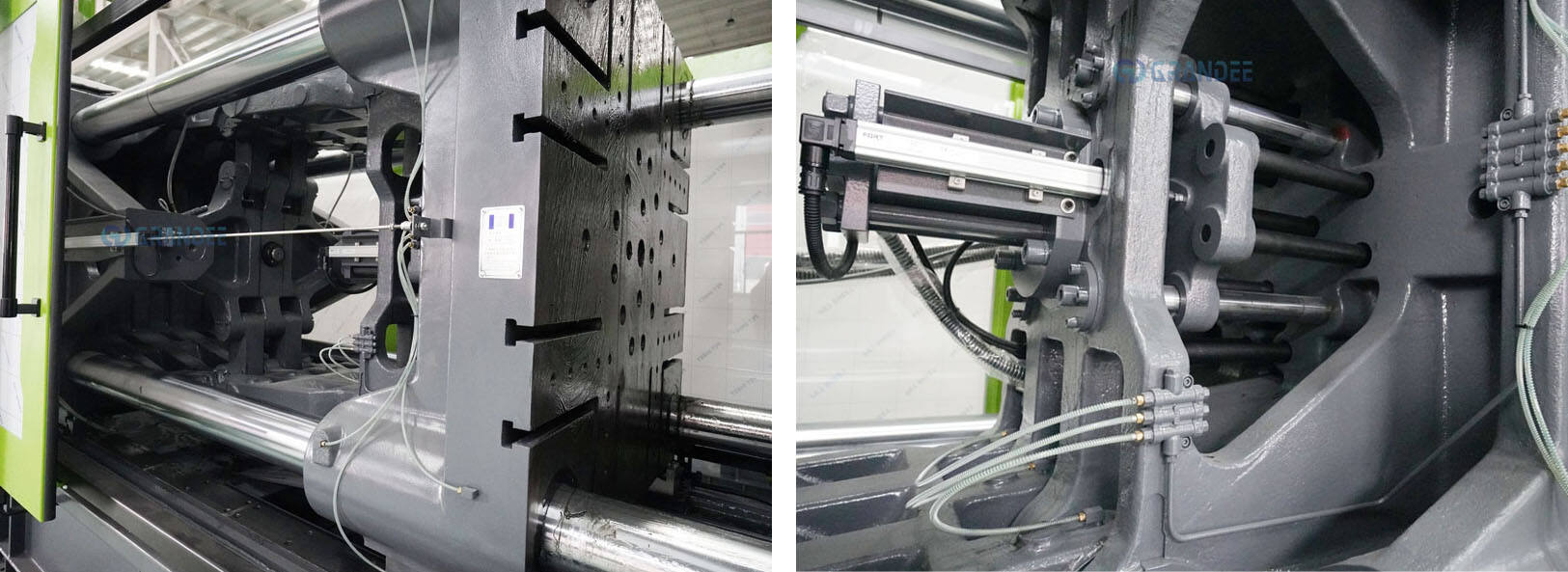

Sistèm Klejan:

sistèm d'atrèt jumè a 5 pwa pou optimizasyon modilaire ak logisel konpoze. Atrèt fò epi rapid ak stabilite, pou satisfo kondisyon atrèt an konsa. Ajustman lè mou nan hydraulik ak sistèm driviye dant pou rapidite ak stabilite. Ajustman awtomatik lè mou an selon fòs atrèt an regle opsyonèl.

Yunit Injeksyon:

Tèknoloji dubl silendri injeksyon balansye fè sikwè a gen fòs distribiye yoniman pandan injeksyon vit, Mote Hydraulik sink wouj ak tor sanble. Sajir pou kondisyon plastisaj ekselan. Rechèch ak devlopman diferens sikw yo selon kondisyon injeksyon diferan, konpatib ak demann progresif ak amelyore kalite injeksyon anpil pi.

Yunit Kontro

Ordinate ekspòte spesyal pou Machin Injeksyon Plastik ak fonksyon anpil ak kontwo presiz. Komponent elektrik mondmè a ak matyèl sirkwi de kvalite superie ak travay stabil ak fiab ann.

NON |

Non |

Marke \Materiyèl |

Jijan |

1 |

Vi\barèl |

Ouwei\/Fuyi\/Tongda, 38CrMoAL |

Chine |

2 |

Twa modèl ak tèt inyeksyon, dezyèm plat |

QT500 |

Chine |

3 |

Mòtè sevo |

Mote Hydralik |

Chine |

5 |

Mote Hydralik |

Delson |

Itali |

6 |

Lamèt Zòn |

Honeywell\/OMRON\/Panasonic |

Etazini\/Japon |

7 |

Lamèt Air |

SCHNEIDER\/LG |

Frans\/Kòre |

8 |

Kontaktele AC |

SCHNEIDER |

FRANS |

9 |

Relè termik |

SCHNEIDER |

FRANS |

10 |

Kontrolè |

TECHMATION |

Taiwan, Chine |

11 |

Rèj elèktronik |

Jiesheng |

Eti Aziken |

12 |

Pòmp |

Oufeite |

Chine |

13 |

Valv solenòid |

YUKEN |

Japon |

14 |

Sgèl lop lajwa |

VALQUA/HALLITE |

Japon/Angleterre |

15 |

KDAS bague dousman |

HALLITE |

Angleterre |

16 |

Kontrolè serval |

Mengde |

Chine |

Sistèm tratman dlo R.O. nan yon etap oswa dezye etap

Reservoir d'Eau Brute → Pomp d'Eau Brute → Filtre à Sable Quartz → Filtre à Charbon Actif → Filtre 5 Microns → Filtre 1 Micron → Pomp à Haute Pression → Dispositif de Dialyse Inversée Primaire → Réservoir Intermédiaire → Pomp Booster → (Pomp à Haute Pression Secondaire → Dispositif de Dialyse Inversée Secondaire) → Mélangeur à Ozone → Pomp d'Eau Pure → Réservoir d'Eau Pure → Pomp d'Approvisionnement Externe → Filtre à Tube en Titane → Approvisionnement Externe → Vers la Machine de Remplissage

Machin automatik pou kol lajan ak etikèt BOPP OPP

Mashin etiketaj BOPP otomatik se pa gen anpil dife pou soti ak diferan materyèl nan kantwon yo ak etikèt yo. Kòs chak etikèt an pi piti, li ka kontan jan mizaje ki gen diferan tè a. Se yon nan modèl ki pi ekonomik pou fè pwodiksyon en mas ak operasyon integre. Machineri a te jwenn kèk dezèn konsept desen modularis pou fasilite pou uzatè a chanje boutèy la. Sipoze de remplaçman roug tankou rouj, lamèd gòn oswa adjistman vites manwayèl a jiska kontwo selikotik ak vites la, tankou chanje etikèt la, li pral dwe chanje pogram PLC la, konsept ki montre ke machineri a te desann pou uzatè a ak konsidèrasyon pou yo reflete nan tout.

Machin etiketaj retréchi PVC PE otomatik

Machin etikè manch ki fonksyone tout automatik la ta bon pou dife senk lòt ti boul, komin boul ron, boul kare, boul oval, e s. Machin an ka alimen e koupe film automatikman, ak li kapab met etikè ak prezision, enpòtan econòmi travay ak eleve efikasite travay. Machin an ka sèvi pou dife senk lòt machandiz, komin boul dlo, boul kozetik, boul shampu, e s.

Prinsip Fonksyonman Machin Pakaj

Machin envelopaj ki fè yon pòs ye bazye sou karakteristik retrait chalou pou film empaquetaj. Li sèvi de senyè fotokoutik pou detekt lajan anlè. Siyèl ki akolte se kontre e traite pa program PLC (kontrolè programab). Band kònveye sèvi pou antre bòt an koninyete, separe bòt yo, ak mèkanizasyon prese. Tout pwoses a fini pa mèkanizasyon konsa: mete bòt, pousye bòt, pousye rod koninyete ak bòt, envelopaj film sèl, chwazi ak fòme film, kanal chof pou retrait ak refroidi ak fòme.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM